A method and system for solving internal tin connection of 0402 type rcl parts

A kind of technology of parts and types, applied in the field of computer board and card manufacturing, can solve problems such as tinning, poor tinning, unreasonable design of PCBPAD, etc., to achieve great economic benefits, save cost resources, and increase production efficiency.

Active Publication Date: 2019-06-25

ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

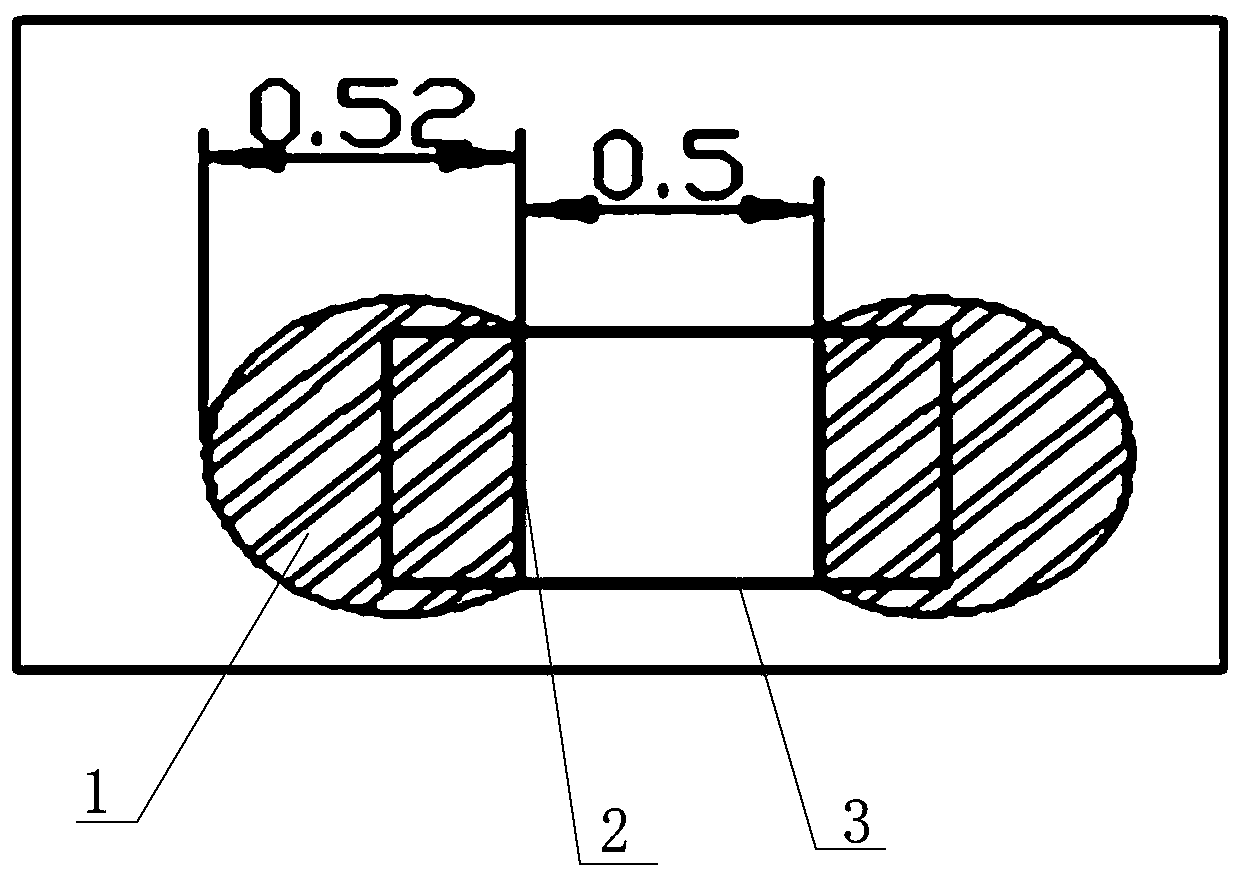

After analysis, it is confirmed that the reason for this kind of internal tin connection is that the PCB PAD design is unreasonable, and the distance between the pads is relatively close. When the solder paste is printed and the parts are attached, the solder paste will definitely be squeezed by the parts. , and the extruded solder paste will be easily connected together, so it is easy to have the problem of internal solder connection, resulting in poor solder connection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Create system:

[0023] A system for solving internal tin connection of 0402 type RCL parts, including,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method and a system for solving the problem of continuous tin electro-deposit inside 0402-type RCL parts. The method includes the following steps: creating a detection module, and detecting the spacing between the two PADs of a current PCB through the detection module; creating a comparison module, and comparing the spacing data of the two PADs detected with the spacing data of two PADs which are proved through simulation to have the problem of continuous tin electro-deposit; and when the spacing between the two PADs detected is smaller than or equal to the spacing between the two PADs which will have the problem of continuous tin electro-deposit, confirming the positions of two electrodes of a part frame, cutting off the inner sides corresponding to the two PADsaccording to the positions of the two electrodes of the part frame to make the distance between the PADs of the PCB reach a spacing without continuous tin electro-deposit. The method and the system are applicable to the production of PCBAs of all electronic products, and can reduce the maintenance cost, board scrap cost, manpower cost and the like brought about by continuous tin electro-deposit. Alot of cost resources are saved, and the output of qualified products is increased. Therefore, the production efficiency is increased, and greater economic benefit is brought to companies.

Description

technical field [0001] The invention relates to the technical field of computer board manufacturing, in particular to a method and system for solving the problem of internal tin connection of 0402 type RCL parts. Background technique [0002] At present, in the field of all PCBA boards such as servers, 0402 (inch) (hereinafter collectively referred to as 0402) type RCL parts can be seen everywhere and are widely used. However, as the size of the parts gradually decreases, the corresponding defects will increase. The basic defects include deviation, tombstone, side standing and other defects. It is difficult to detect the poor tin connection with the naked eye, especially the internal tin connection, which can only be checked by some perspective inspection machines (such as X-RAY inspection machine), or by some functional testing methods. After analysis, it is confirmed that the reason for this kind of internal tin connection is that the PCB PAD design is unreasonable, and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05K3/00

Inventor 张小行

Owner ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com