Forcible-arrangement forcible-starting corn straight-inserting hole-sowing machine

A seeder and corn technology, applied to seeder parts, sowing, agriculture, etc., can solve the problems of difficult sowing, picking film, scraping film, long seed germination period, etc., and achieve the effect of alleviating the impact of the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

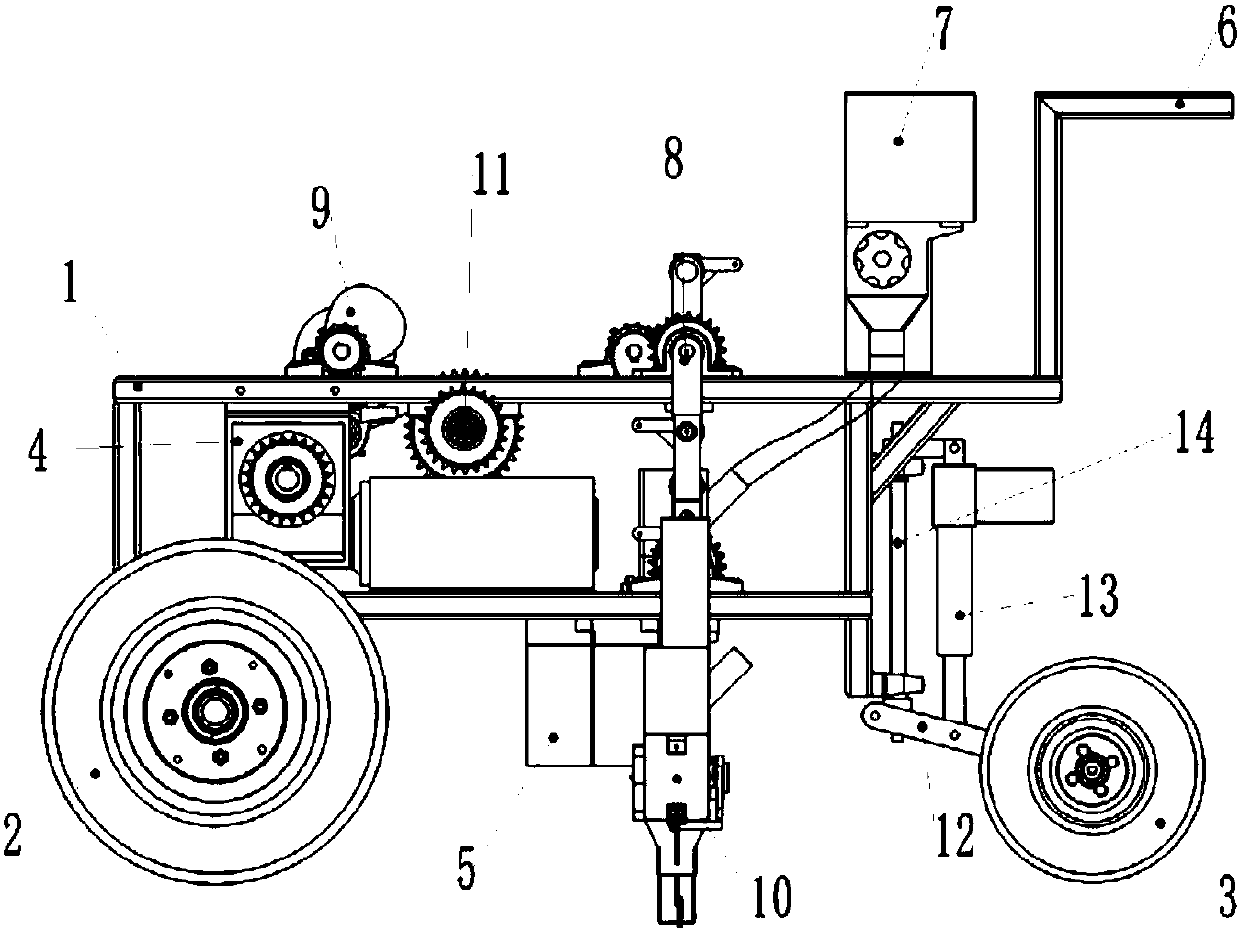

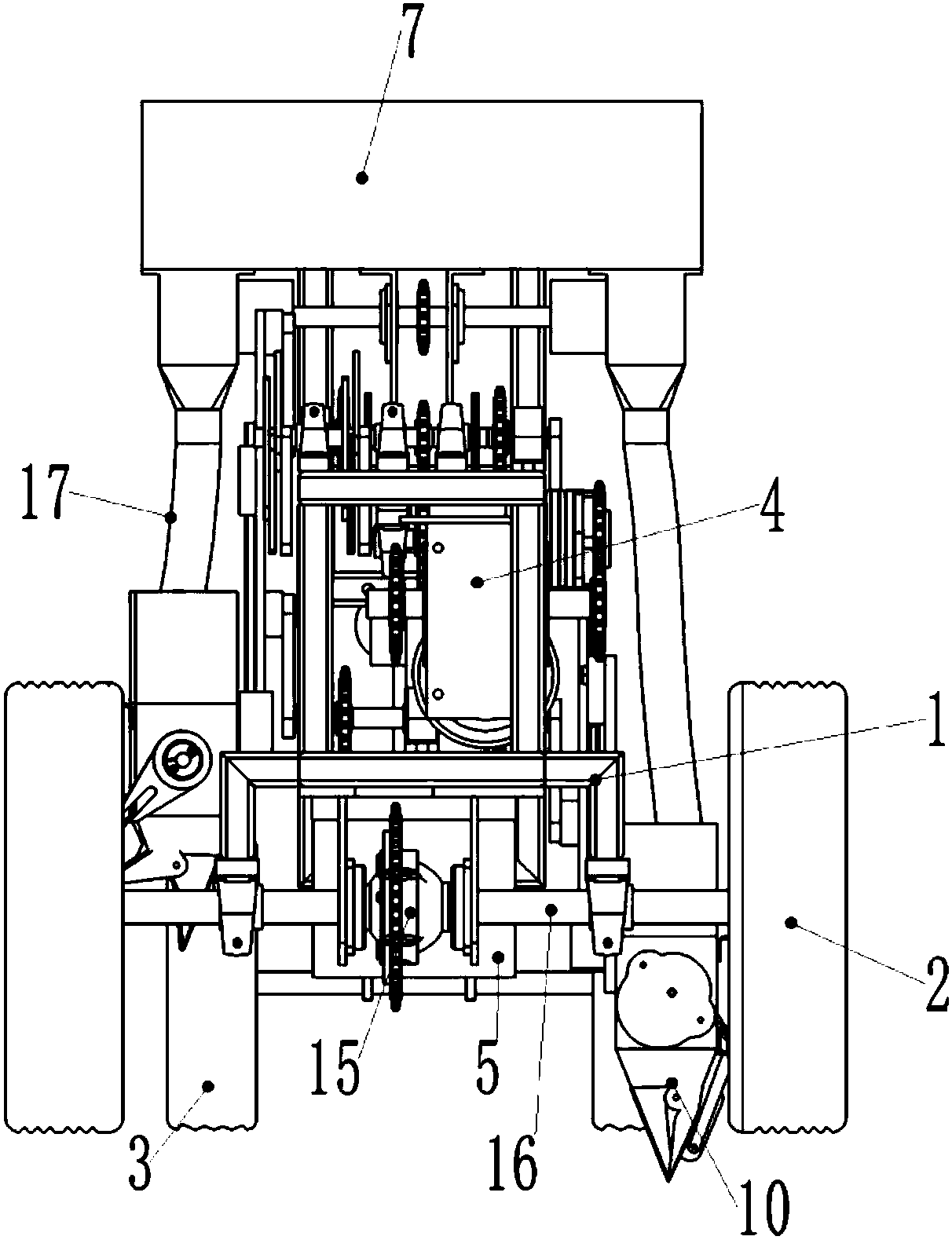

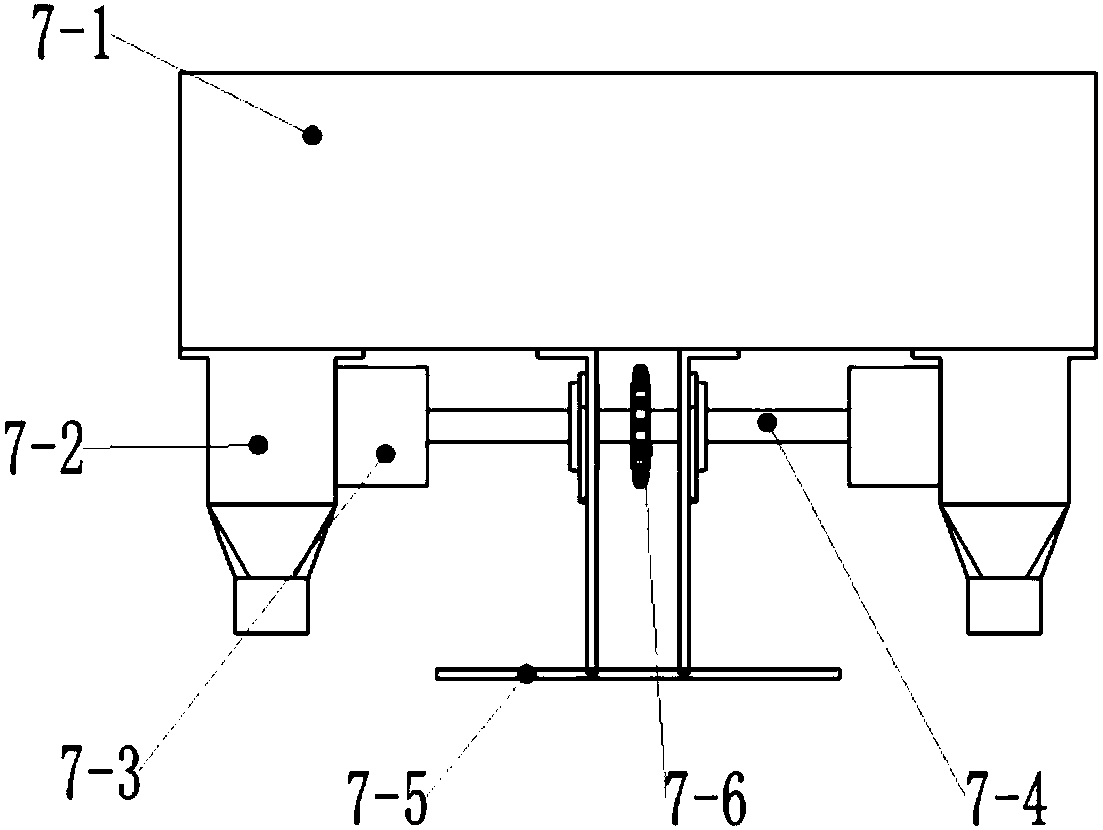

[0024] Such as Figures 1 to 9 As shown, the described a kind of strong discharge and strong start corn direct insertion hole planter includes a frame 1, which is characterized in that the front of the outer lower end of the frame 1 is connected with the front wheel shaft 16 through a bearing with a seat, and the middle of the front wheel shaft 16 The position is provided with a differential 15, the two ends of the front wheel shaft 16 are provided with front wheels 2, the front end of the frame 1 is equipped with a motor 4, the power output shaft of the motor 4 is connected with the differential 15 through a sprocket mechanism, and the inside of the frame 1 An electromagnetic clutch 11 is installed on the upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com