Lifting garment processing table

A lifting type and processing table technology, applied in the direction of sewing clothes tools, etc., can solve the problems of inconvenient operation, affecting the efficiency and quality of clothing processing, and achieve the effects of improving efficiency and quality, improving heat dissipation, and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

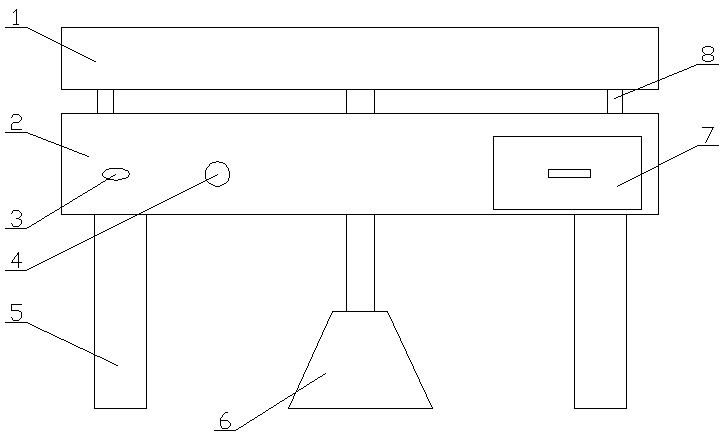

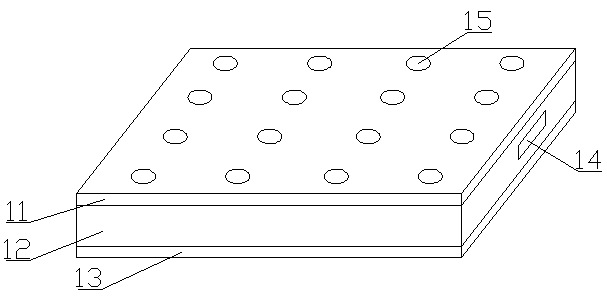

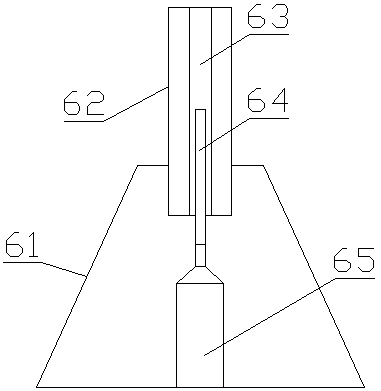

[0026] like figure 1 As shown, this embodiment describes an elevating garment processing table, including a table top 1, a console 2, a column 5 and a lifting mechanism 6, the table 1 is detachably arranged on the top of the console 2, and the console 2 The bottom of the console 2 is provided with a plurality of pillars 5, and the side of the console 2 is provided with at least one storage box 7, which can be used to prevent tools such as small sewing machines, irons, scissors, and the lifting end of the lifting mechanism 6 Pass through the console 2 and connect with the bottom of the table top 1. By designing a detachable connection between the table top 1 and the console 2, and connecting the lifting end of the lifting mechanism 6 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com