Rectangular external spline machining method suitable for numerical control turning center

A processing method and external spline technology, applied in the field of CNC turning parts processing, can solve the problems of high manufacturing cost, long processing cycle, difficult to popularize and apply, etc., and achieve simple and efficient processing methods, shortened processing period, and simple processing steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A method for machining rectangular external splines suitable for CNC turning centers, characterized in that it comprises the following steps:

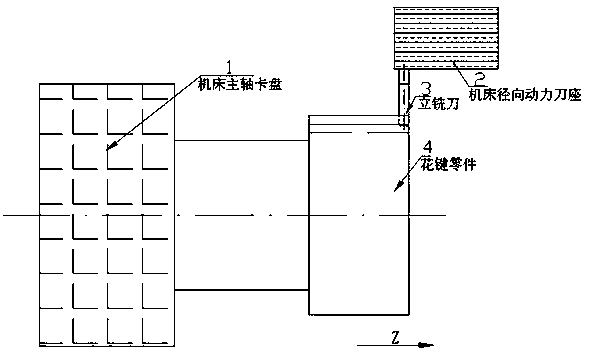

[0029] a: Parts and tools are installed as figure 1 As shown, tool selection, according to the material of the workpiece to be processed, select the material of the milling cutter, the diameter of the roughing tool should be smaller than the width of the keyway, and the diameter D of the finishing tool should be less than or equal to 1 / 2 the width of the keyway W (ie D≤1 / 2W), The bottom angle r of the milling cutter is equal to the fill angle R of the keyway (that is, r=R);

[0030] b: Rough machining of the keyway of the external spline, leaving a margin of 0.1~0.2mm on each surface;

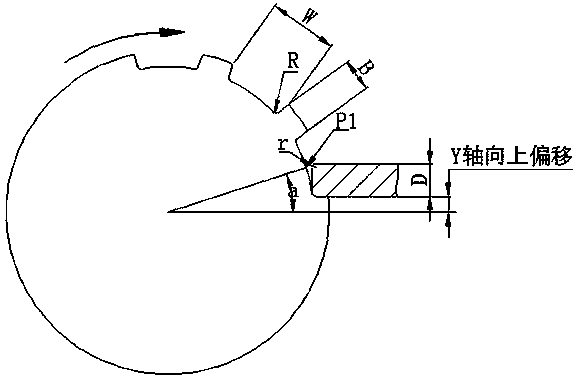

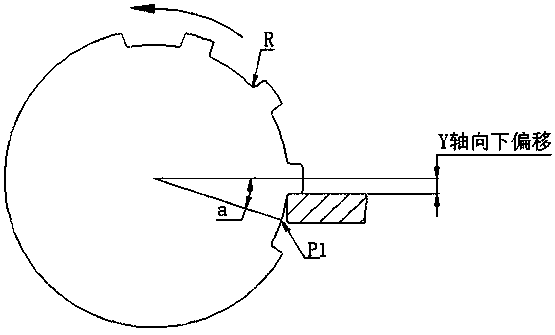

[0031] c: if figure 2 As shown, the fine milling of the upper side teeth of the spline is performed by using the precise positioning function of the C-axis of the turning center to rotate and position the spline teeth horizontall...

Embodiment 2

[0039] A method for machining rectangular external splines suitable for numerically controlled turning centers, characterized in that it comprises the following steps:

[0040] a: According to the material of the processed part, select the material of the milling cutter. The diameter of the roughing tool should be smaller than the width of the keyway, the diameter D of the finishing tool should be less than or equal to 1 / 2 the width of the keyway W, and the bottom angle r of the milling cutter is equal to the fillet angle R of the keyway;

[0041] b: Rough machining of the keyway of the external spline, leaving allowances on each surface;

[0042] c: Finish milling the upper side teeth of the spline obtained in step b, use the precise positioning function of the C-axis of the turning center to rotate and position the spline teeth horizontally, and then use the Y-axis function of the turning center to offset the tool upward by 1 / 2 tooth width B;

[0043] d: Quilt the upper ha...

Embodiment 3

[0048] A method for machining rectangular external splines suitable for numerically controlled turning centers, characterized in that it comprises the following steps:

[0049] a: According to the material of the processed part, select the material of the milling cutter. The diameter of the roughing tool should be smaller than the width of the keyway, the diameter D of the finishing tool should be less than or equal to 1 / 2 the width of the keyway W, and the bottom angle r of the milling cutter is equal to the fillet angle R of the keyway;

[0050] b: Rough machining of the keyway of the external spline, leaving allowances on each surface;

[0051] c: Finish milling the upper side teeth of the spline obtained in step b, use the precise positioning function of the C-axis of the turning center to rotate and position the spline teeth horizontally, and then use the Y-axis function of the turning center to offset the tool upward by 1 / 2 tooth width B;

[0052]d: Quilt the upper hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com