Rapid clearing method for inner wall burrs of pipes

A technology for burrs and pipe fittings, which is applied in the field of rapid removal of burrs on the inner wall of pipe fittings, can solve the problems of reducing the service life of steel pipes, reducing strength, and reducing the stability of steel pipes, so as to reduce the probability of stress fracture, strengthen support stability, and improve transportation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

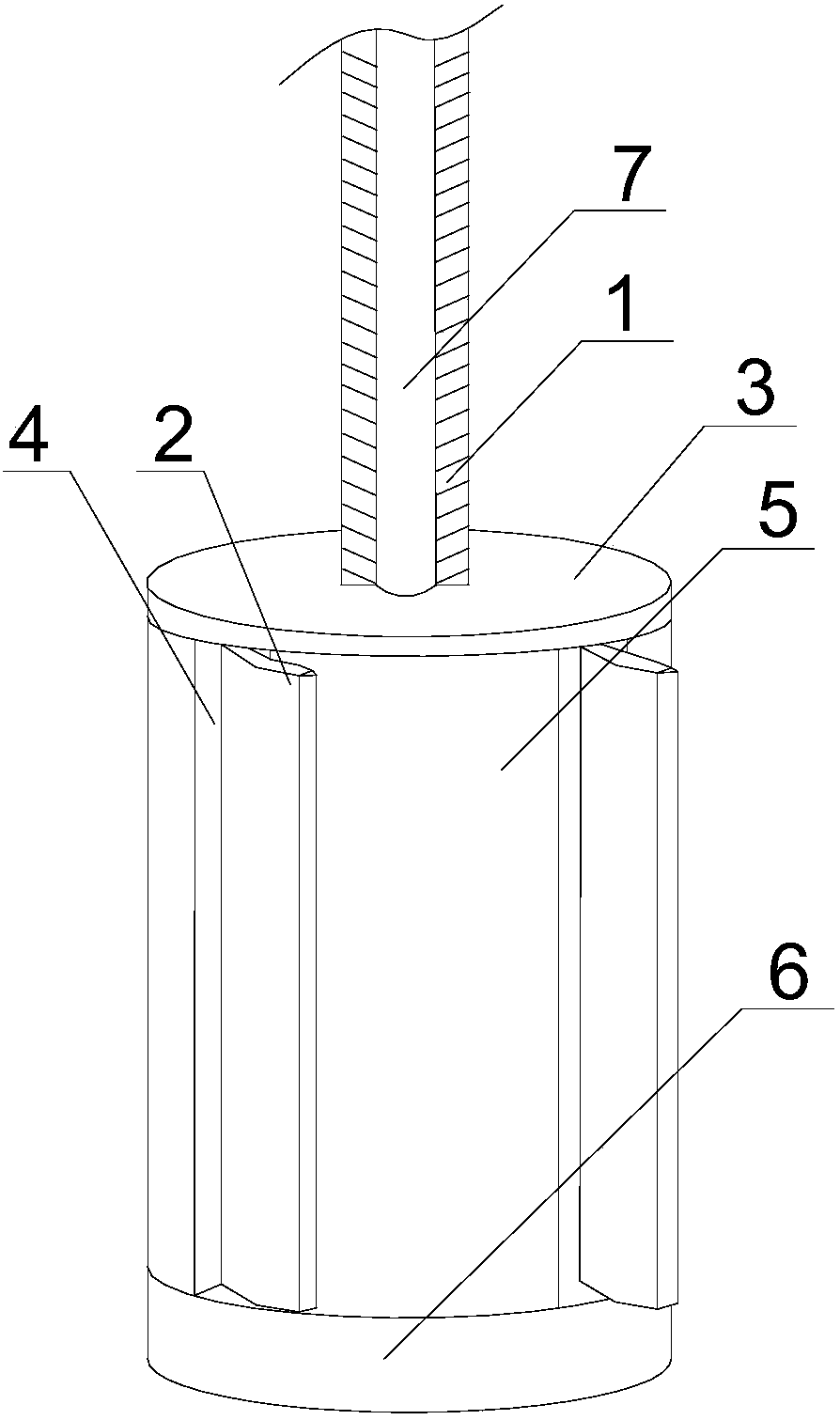

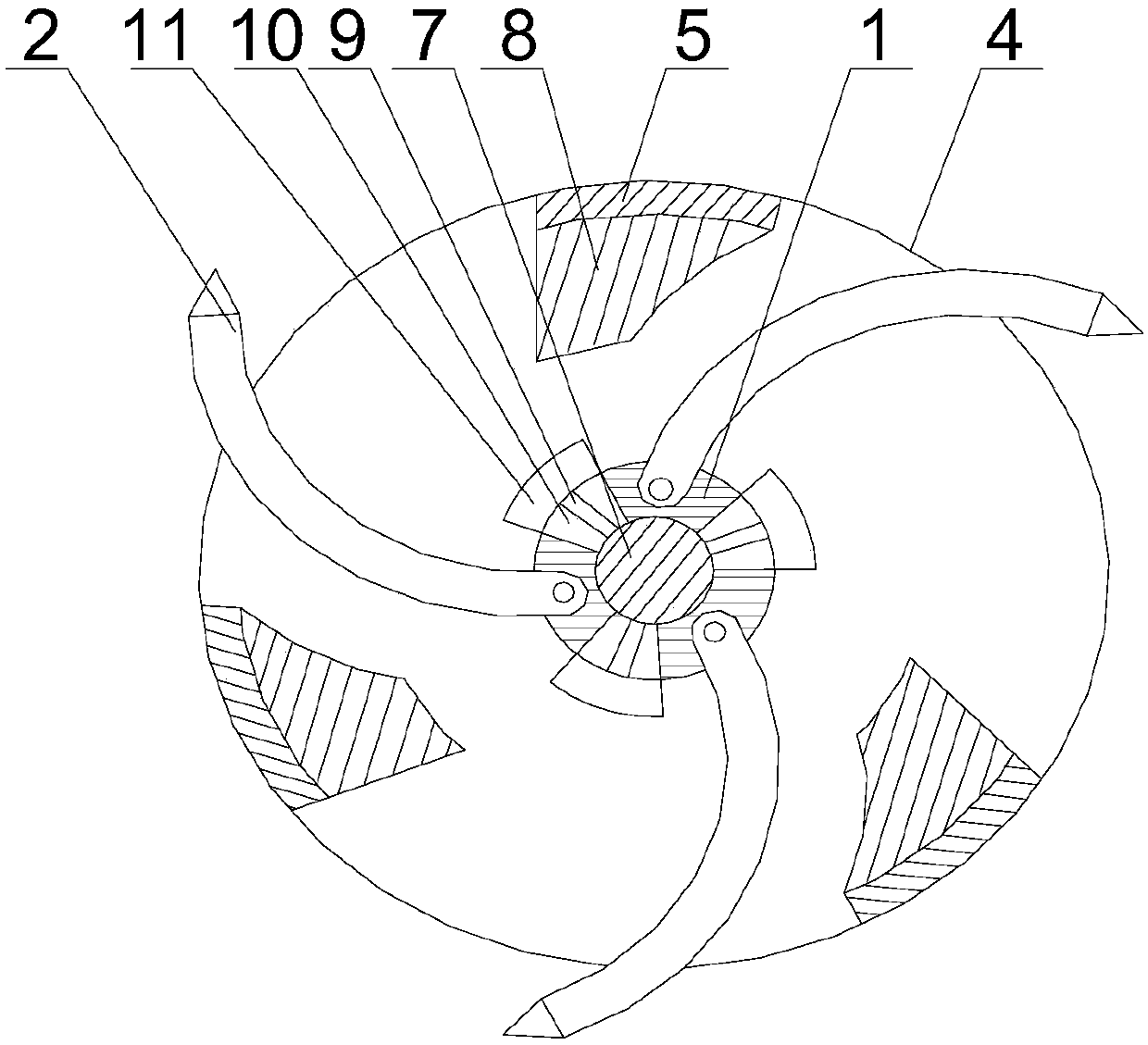

[0019] Such as figure 1 and figure 2 As shown, in this embodiment, according to the specific size of the inner diameter of the steel pipe, by rotating the screw, the relative movement between the screw and the central axis occurs, and the connecting rod moves in the fan-shaped hole while driving the stopper to move accordingly, realizing the stopper and cutting. The distance between the slices increases or decreases, forcing the position of multiple cutting slices to change, that is, the part of the cutting slices extending outward through the adjustment hole increases or decreases, so that the excessive movement of the blade tips of the multiple cutting slices The size of the annular area matches the inner diameter of the steel pipe, and then the external drive equipment drives the central shaft to rotate, and the cutting blade on the central shaft rotates to start cleaning the dirt on the inner wall of the steel pipe;

[0020] Wherein, the fixed plate 3 will be sealed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com