Rotary moving material distributing machine

A distributing machine and rotary motion technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of dust pollution, environmental protection not up to standard, spreading materials, etc., achieve high reliability and prevent belt deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

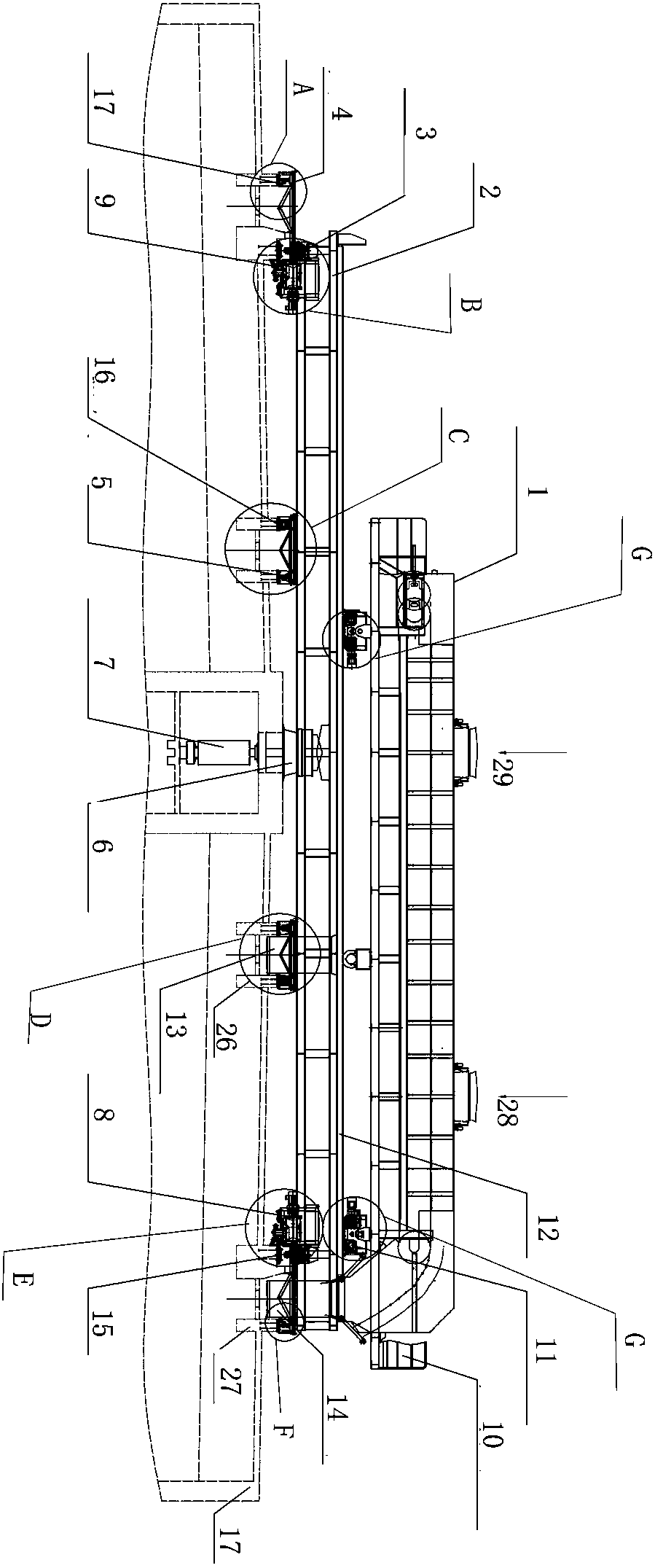

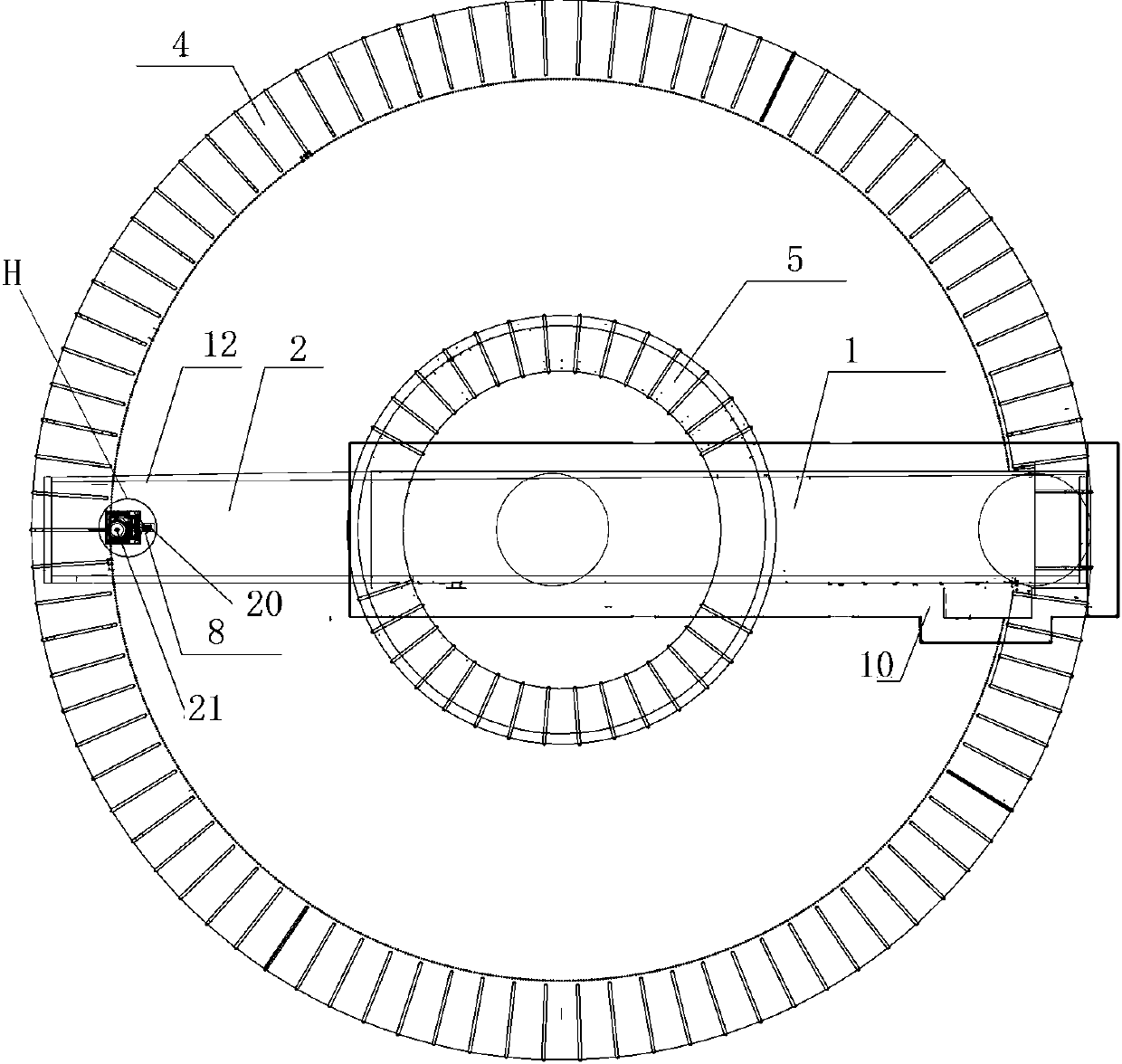

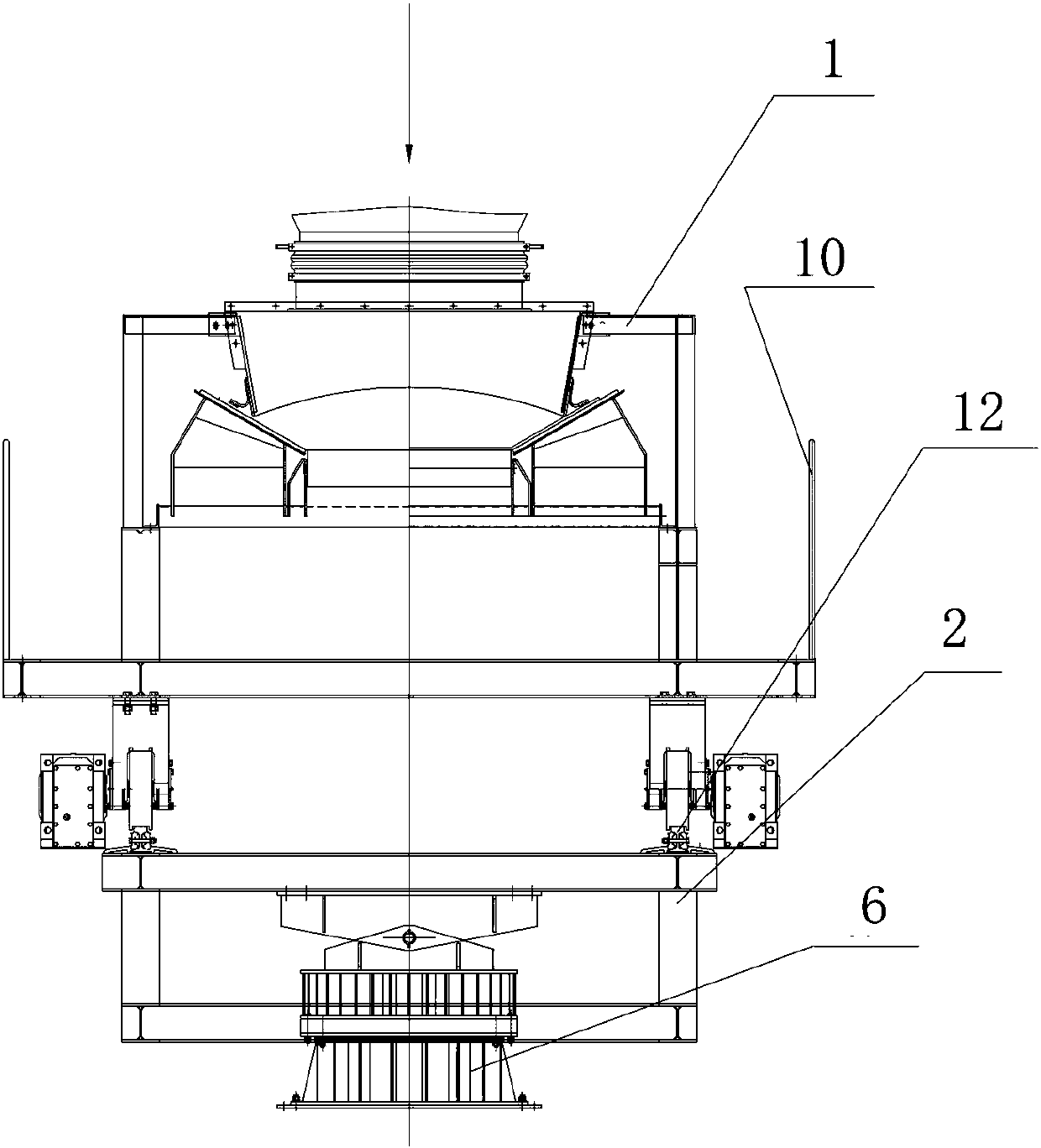

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The present invention provides a rotating and moving distributing machine, which includes a silo 18. The silo 18 can be provided with a plurality of distributing annular grooves 19 according to the diameter of the silo and the actual demand. In fact, each distributing annular groove 19 consists of two The ditch wall and two ditch walls form, and the top of each distribution annular ditch 19 is provided with an annular track 15, which is convenient for the bearing platform 2 to perform a 360-degree circular rotation on the annular track. The upper part of the bearing platform 2 is laid with a A double track composed of two parallel linear rails 12, the linear rail 12 is equipped with a mobile closed belt conveyor 1 that reciprocates linearly along the linear rail 12, and the mobile closed belt conveyor 1 combined with a UPE slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com