Gravity type explosion door with torsion spring

An explosion-proof door, gravity type technology, applied in the door, combustion method, combustion chamber and other directions of the combustion chamber, can solve the problems of inability to automatically return to position, high maintenance cost, poor sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

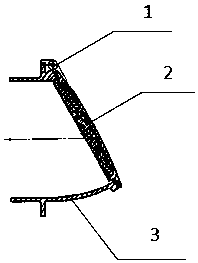

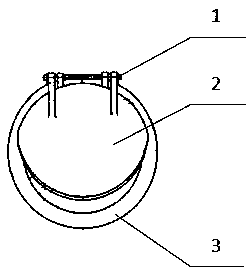

[0011] see figure 1 , figure 2 A torsion spring gravity type explosion-proof door, including a flange plate, torsion spring, and a protective cover, the flange plate is fixedly installed on the sleeve at the tail of the boiler and connected with the explosion-proof door protective cover with a torsion spring, the explosion-proof door The outlet of the outlet is obliquely arranged and covered with a protective cover, and the edge of the flange plate is provided with a groove to adapt to the edge protrusion of the protective cover, and the edge protrusion of the protective cover is polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com