Adaptive Robust Control Method for Launch Platform Based on Friction Compensation

A self-adaptive robust, launch platform technology, applied in the control field, can solve the problem of not considering friction compensation, and achieve the effect of simple controller, easy engineering practice, and excellent control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

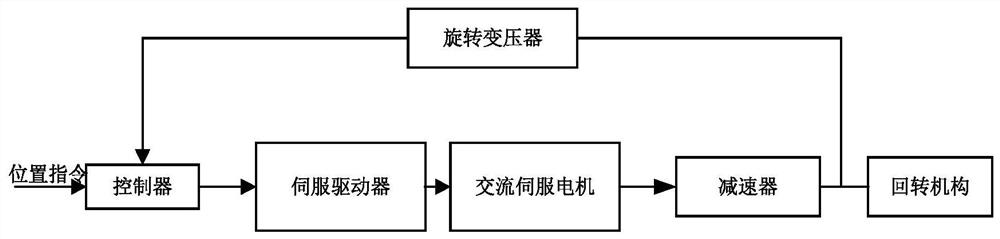

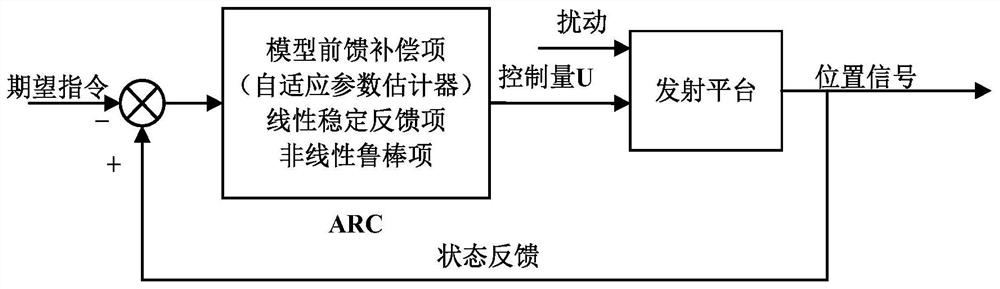

Method used

Image

Examples

Embodiment

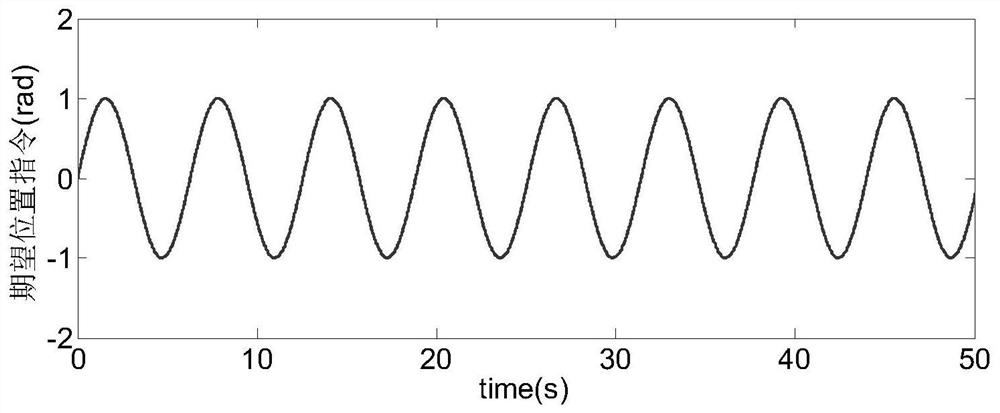

[0077] The simulation parameters are: m=0.2kgm 2 , T L =2Nm,d=0.03x 1 x 2 , σ 0 =0.03Nm / rad,σ 1 =0.8Nms / rad,σ 2 =0.65Nms / rad,F s =2.19Nm,F c = 16.69 Nm. The position reference tracking signal is chosen as x 1d =sin(t). The parameters of the adaptive robust controller (ARC) are: k1=180, k2=60, k=20, Δ 1 =1.449,Δ 2 =17.12, Γ=diag{0.01, 0.0003, 1.0, 0.001}.

[0078] image 3 is the tracking signal expected by the system. Figure 4(a) and Figure 4(b) are the position tracking error curves of ARC and PID controllers. It can be seen from the figure that the tracking error of the ARC controller is much smaller than that of the PID controller. Figure 5 is a graph of parameter estimation by the controller designed in the present invention. It can be seen from the figure that even if the exact value of the parameter cannot be obtained, we can realize its self-adaptation through the ARC controller and obtain a good tracking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com