Anti-side-rolling torsion bar assembly automatic positioning and assembling device and method

An anti-roll torsion bar and automatic positioning technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that the automatic positioning and assembly of torsion bar components cannot be realized, so as to improve assembly accuracy and efficiency and reduce labor intensity , the effect of quick changeover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

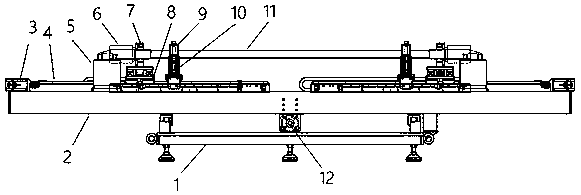

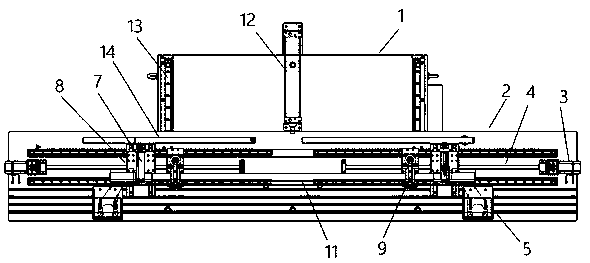

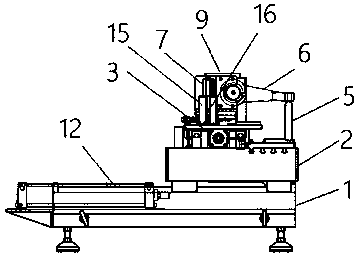

[0031] Please refer to Figure 1 to Figure 3 , the anti-roll torsion bar assembly includes a torsion bar shaft 11 and a torsion arm 6 . Automatic positioning and assembly equipment for anti-roll torsion bar components, including frame 1 (integral frame can be used), table panel 2, table panel displacement mechanism, automatic clamping device, automatic centering device, and control system (not shown in the figure ), the assembly limit device, the circumferential positioning block 5 and the manipulator installed on the frame (not shown in the figure).

[0032] The table top is mounted on the frame and can move back and forth on the frame. The table top displacement mechanism includes a table top guide rail 13 and a table top cylinder 12 installed on the frame, the table top is installed on the frame through the table top guide rail, and the table top cylinder is connected to the table top; the table top displacement mechanism is connected to the control system. The table top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com