Device and method for measuring flank wear of ball end milling cutter

A ball-nose milling cutter and measuring device technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems that affect the milling precision tool life, the measurement accuracy cannot be guaranteed, and the flank structure is complicated. , to achieve the effect of simple and feasible method, shortened measurement time and high authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

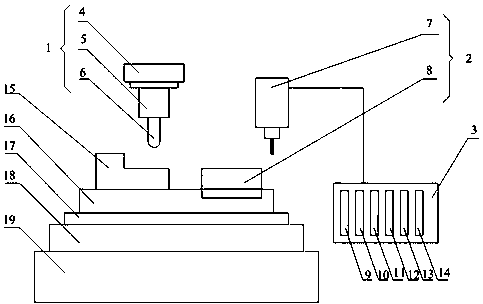

[0028] A ball end milling cutter flank wear measuring device, which consists of: hardware and software parts, the hardware includes: processing device 1, re-image device 2 and tablet computer 3 three parts, the tablet computer is equipped with special Three-coordinate measurement software, tool wear measurement software and windows system, the processing device includes a frame 4, the frame is connected to the main shaft 5, the main shaft is connected to the ball end milling cutter 6, and the re-imaging device It includes a three-coordinate measuring instrument 7 and a re-image board 8, and the three-coordinate measuring instrument is connected to a tablet computer.

Embodiment 2

[0030] According to the ball end milling cutter flank wear measuring device described in Embodiment 1, the ball end milling cutter is connected with the closed milling machine spindle, and a workpiece 15 is placed under it, and the workpiece connection fixture 16, the The clamp is fixed on the connecting plate 17 , the connecting plate is installed on the fixing block 18 , and the fixing block is installed on the base 19 .

Embodiment 3

[0032] According to the ball end milling cutter flank wear measuring device described in embodiment 1 or 2, a mirror plate is placed under the three-coordinate measuring instrument, the mirror plate is connected to a fixture, and the fixture is fixed on the connection The connecting plate is installed on the fixed block, and the fixed block is installed on the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com