One-machine six-mode fully-integrated direct current pile power distribution device

A distribution device and technology, applied in the field of charging piles, can solve the problems of imprecise protection logic, large installation space requirements, complicated wiring and control, etc., and achieve the effect of ensuring automatic identification, reducing equipment costs, and simplifying power control strategies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

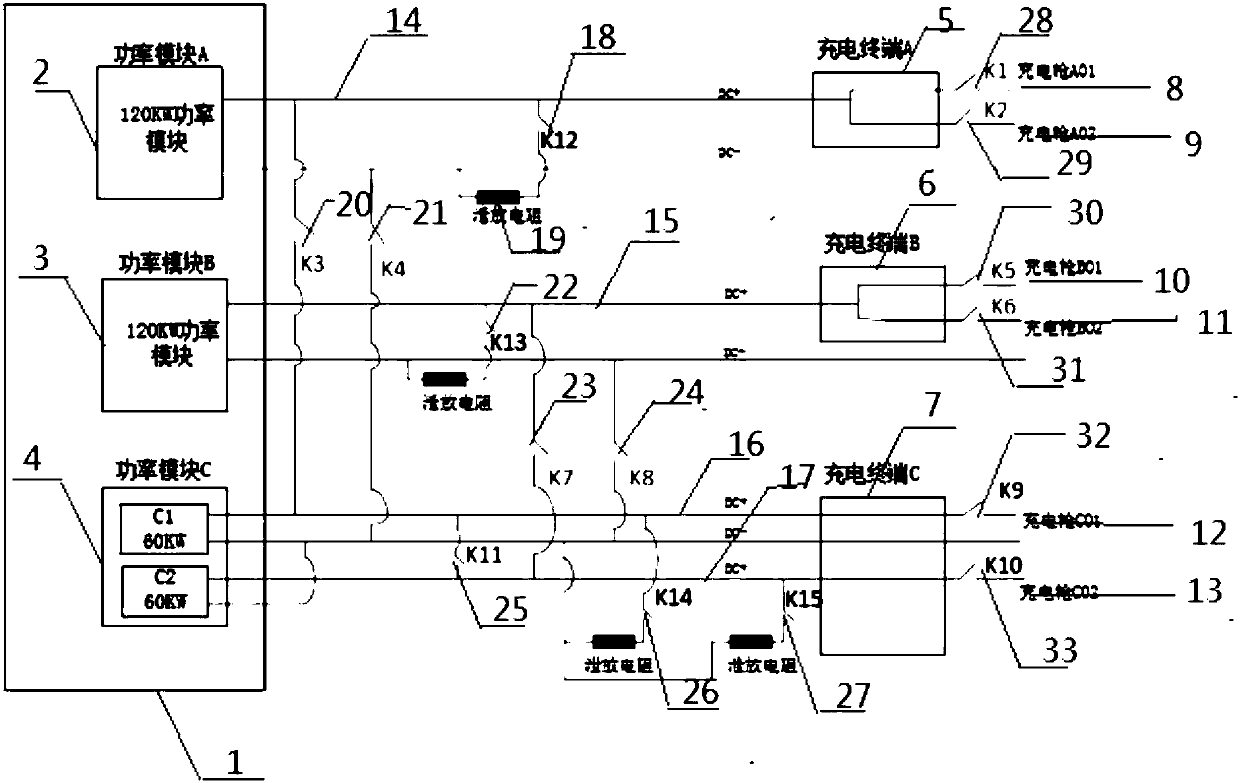

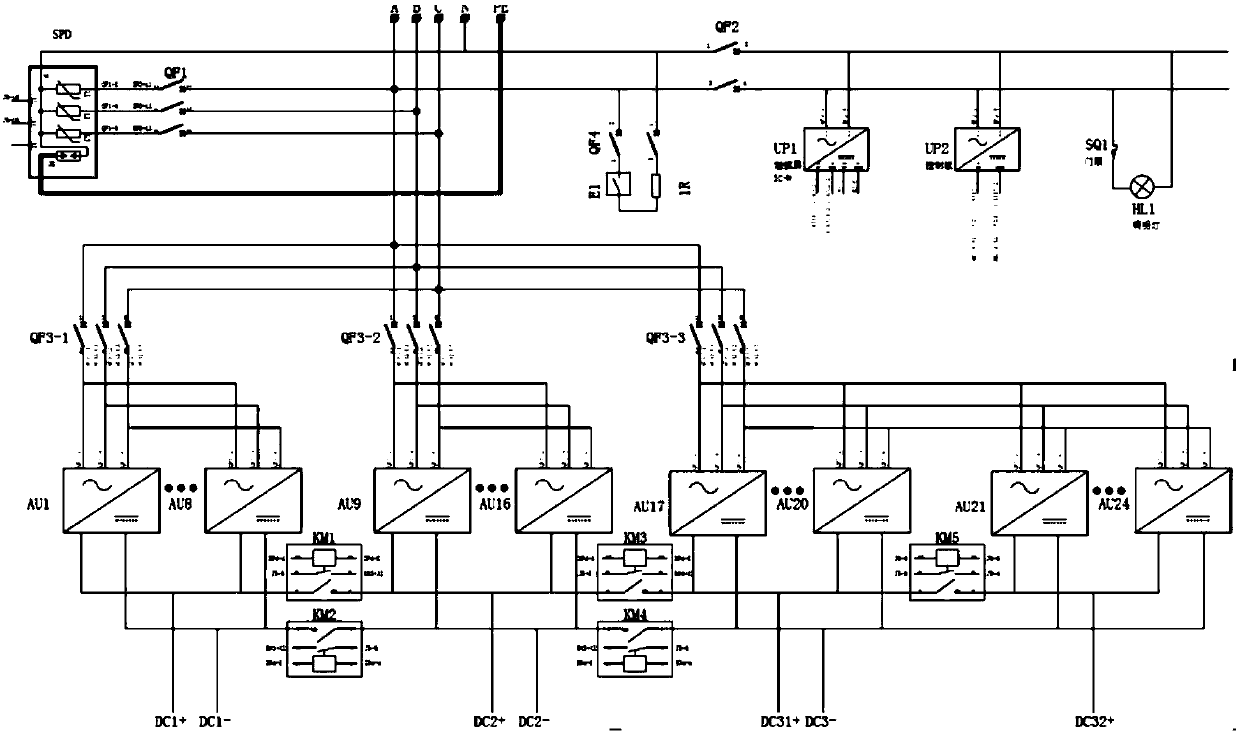

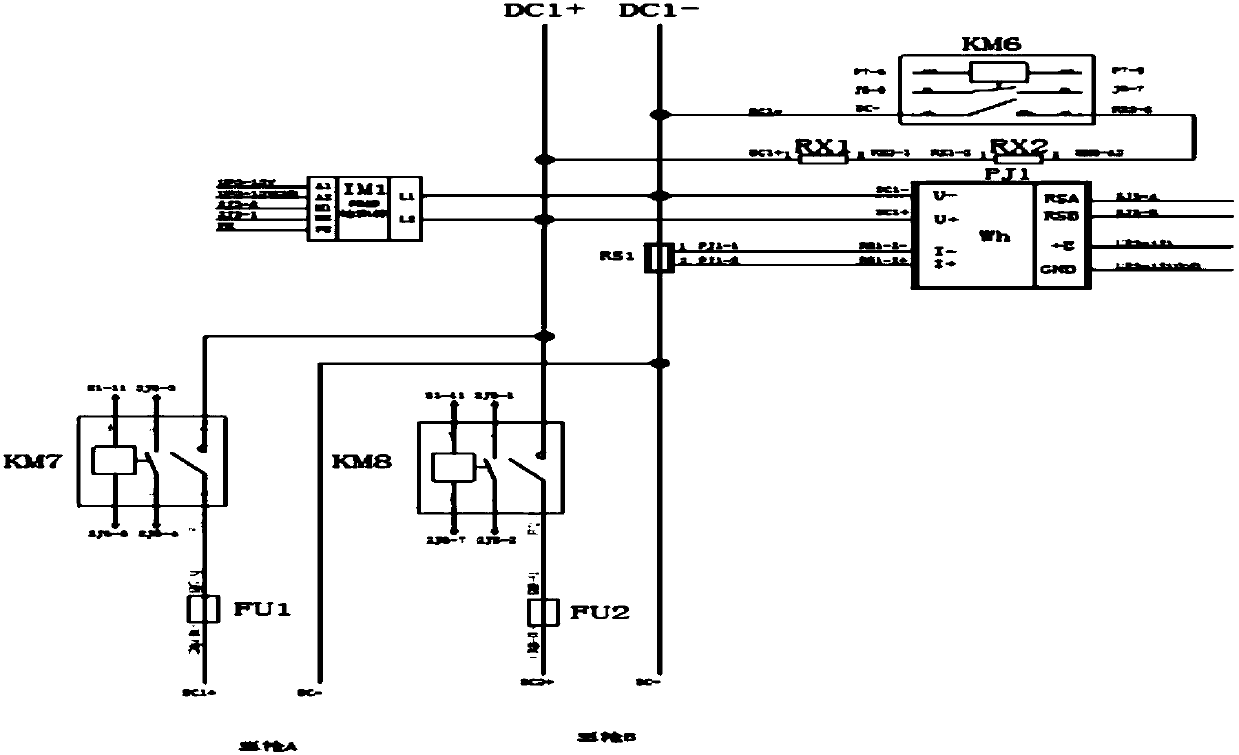

[0019] Such as Figure 1-5 As shown, the present invention provides a one-machine six-full body DC pile power distribution device, including a power cabinet and a charging terminal, and the power cabinet is provided with a power module A, a power module B, a power module C, a controller, a charging module, LCD screen, cascaded DC contactor, emergency stop switch and cable. The charging terminal is composed of charging terminal A, charging terminal B and charging terminal C. The charging terminal is equipped with a main controller, LCD screen, card reader, indicator light, DC contactor and fuse; charging terminal A is electrically connected to charging gun A01 and charging gun A02 through a cable, charging terminal B is electrically connected to charging gun B01 and charging gun B02 through a cable, charging terminal C is electrically connected to charging gun C01 through a cable It is electrically connected to the charging gun C02, the power module A is electrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com