A system and method for direct pyrolysis of high-temperature bubbling methane driven by concentrated solar energy to produce high-purity hydrogen

A technology of concentrating solar energy and high-purity hydrogen, applied in chemical instruments and methods, hydrogen, energy input, etc., can solve the problems of reactor channel blockage, a large amount of high-temperature heat energy, and low reaction purity, so as to achieve zero-carbon emission performance and ensure effective Effects of utilization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

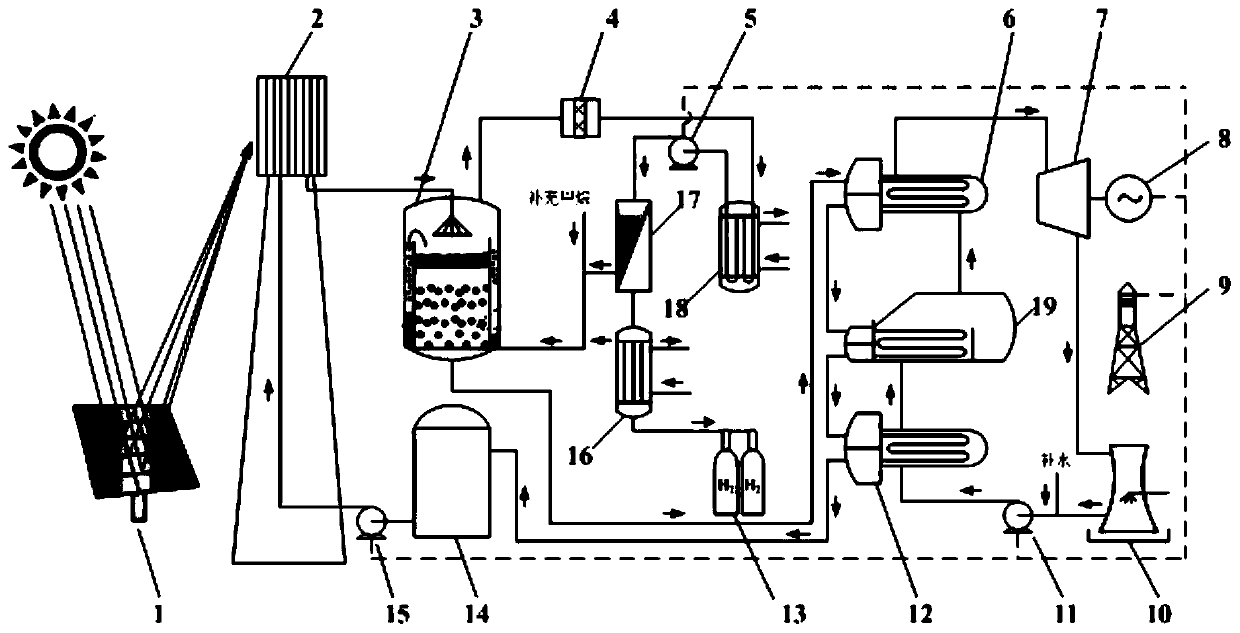

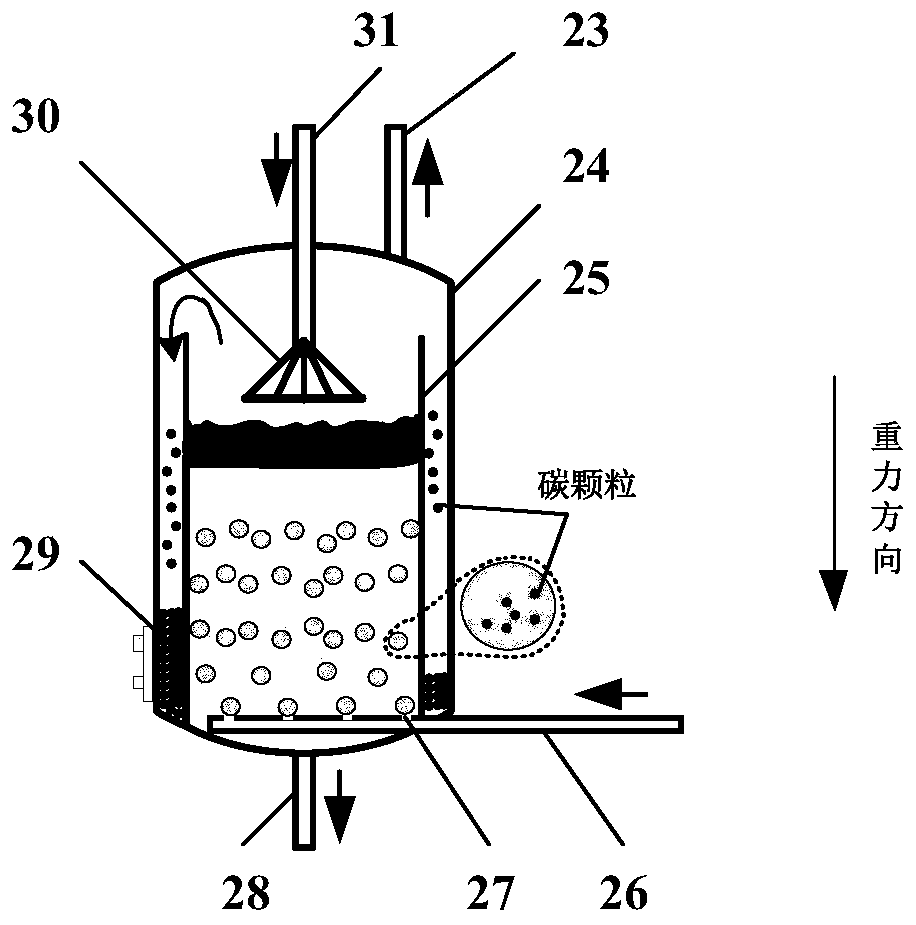

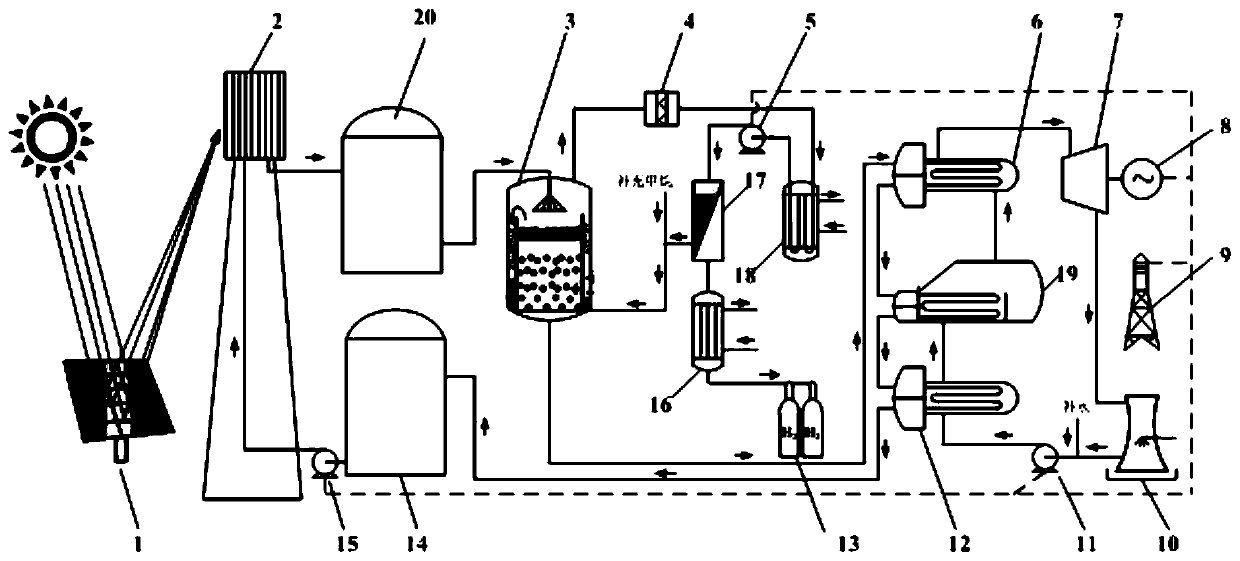

[0024] see figure 1 , a mode that operates only during the day. The advantage of this mode is that it is small in scale and low in cost, but it cannot run continuously 24 hours a day. At this time, the system can be divided into a high-temperature heat transfer fluid circulation loop, a methane cracking reaction circulation loop and a water-steam circulation loop. The concentrator 1 collects and concentrates the solar energy on the heat absorber 2, and the heat-carrying fluid is transported from the low-temperature heat storage tank 14 through the high-temperature heat-carrying fluid circulation pump 15 to the heat absorber 2, and the high-temperature heat-carrying fluid heated by the heat absorber 2 Into the bubble reactor 3, its structure is as figure 2 shown. In the bubble reactor 3, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com