Fan blade step array type ultrasonic shot peening device and method

A technology of ultrasonic shot peening and fan blades, which is applied in the field of metal surface shot peening, can solve the problems of fan blade strengthening, low efficiency of ultrasonic shot peening, etc., and achieve the effect of improving efficiency and solving recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

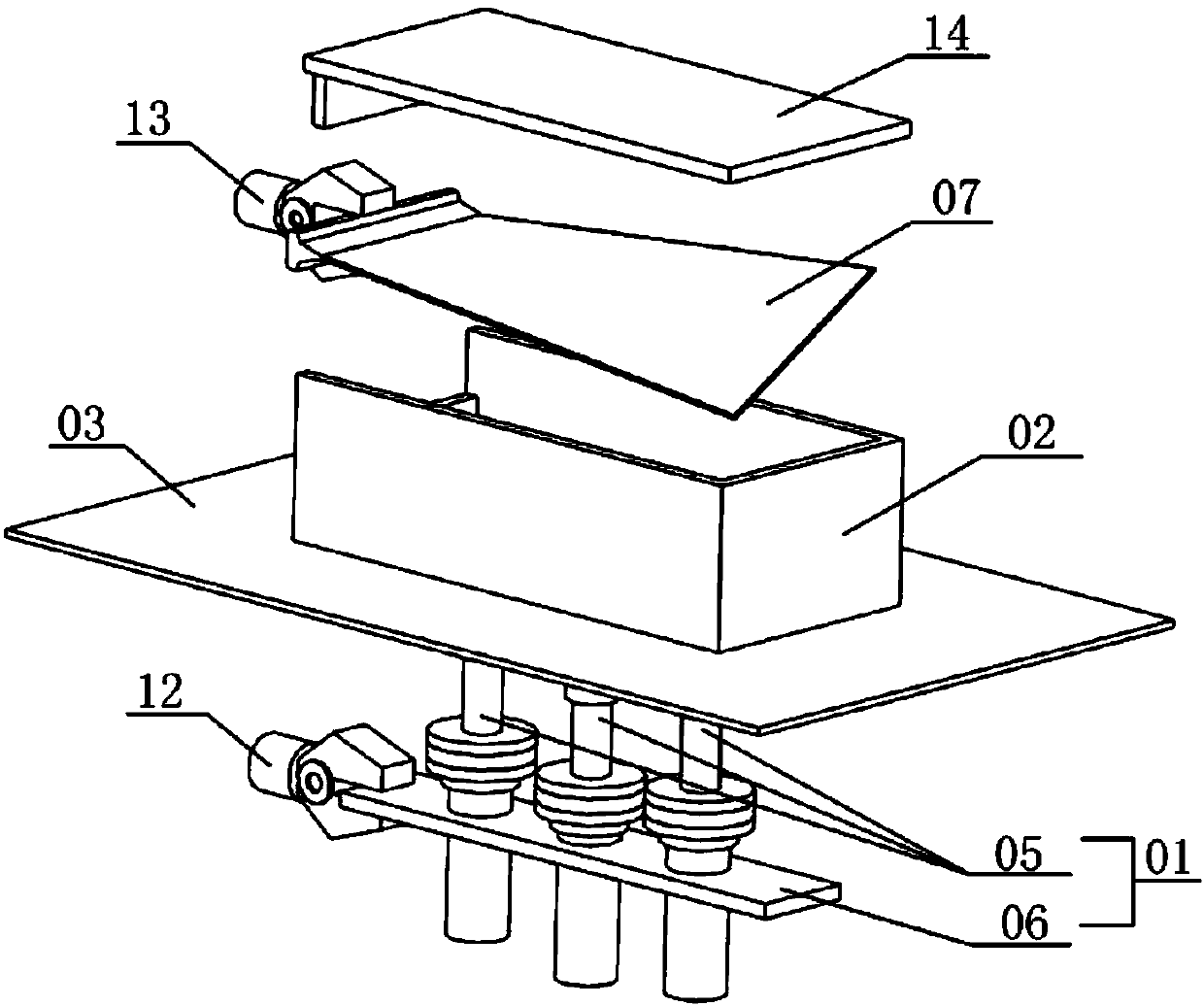

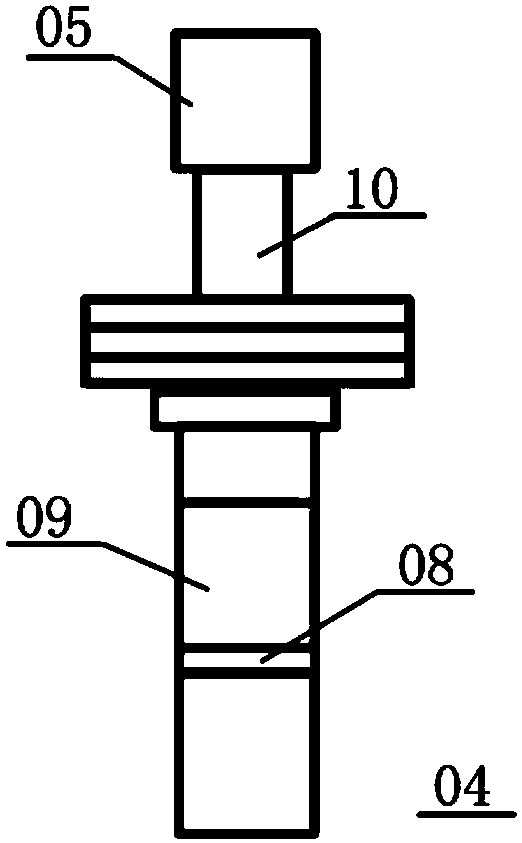

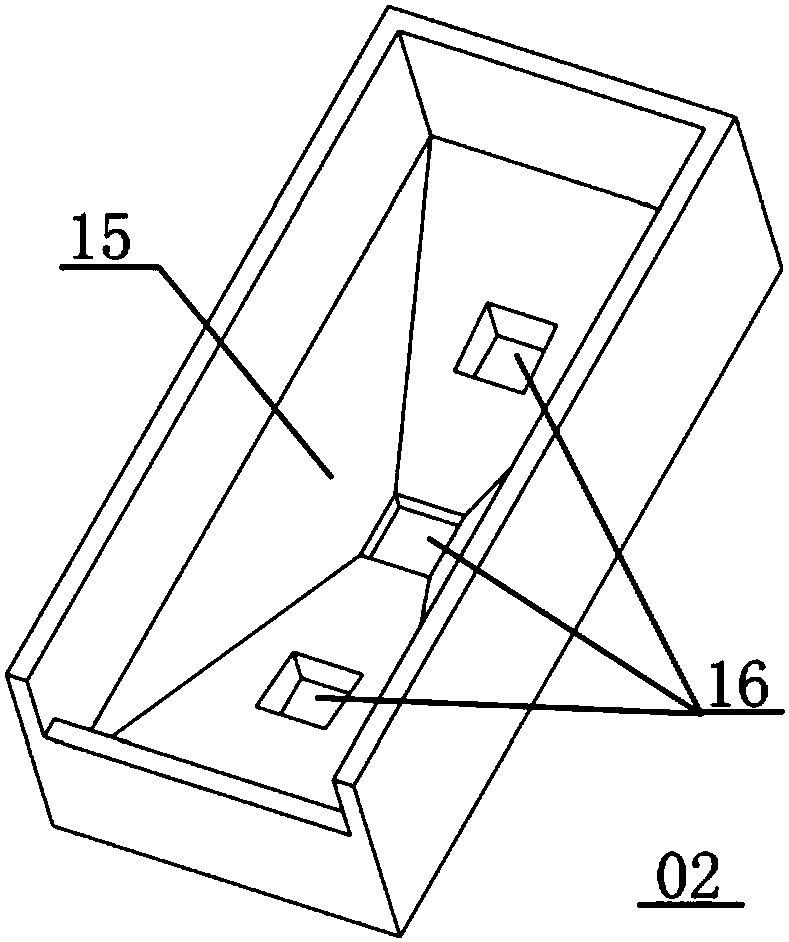

[0027] refer to figure 1 with figure 2 , a stepped array ultrasonic shot peening device for fan blades disclosed in this embodiment includes: a stepped ultrasonic vibration equipment array 01, a shot peening chamber 02 and a workbench 03, and the stepped ultrasonic vibration equipment array 01 consists of three Ultrasonic vibration equipment 04 is arranged and composed. The vibrating heads 05 of the three ultrasonic vibrating equipment 04 are arranged in a ladder shape and installed on the vibrating head clamping device 06. Installed on the workbench 03, the shot blasting chamber 02 is used to accommodate the fan blade 07, the fan blade 07 is a part with a large metal plane structure, the length of the fan blade 07 is between 300mm and 800mm, the vibration of the three ultrasonic vibration devices 04 The head 05 can move through the bottom of the workbench 03 and stretch into the shot blasting chamber 02. Three vibrating head mounting holes 16 and three openings are respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com