Pollution-free equipment for construction

A construction, pollution-free technology, applied in construction, sheet pile wall, infrastructure engineering, etc., can solve problems such as difficulty in manual control of mechanical movement and removal, environmental pollution, large vibration, etc., to improve accuracy and stability, The effect of reducing labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

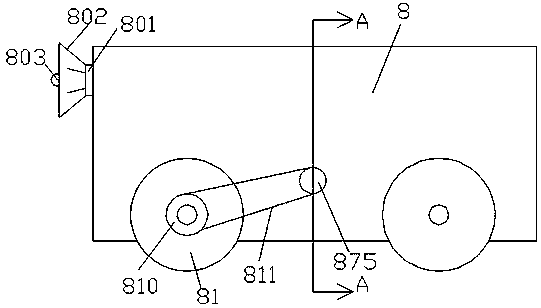

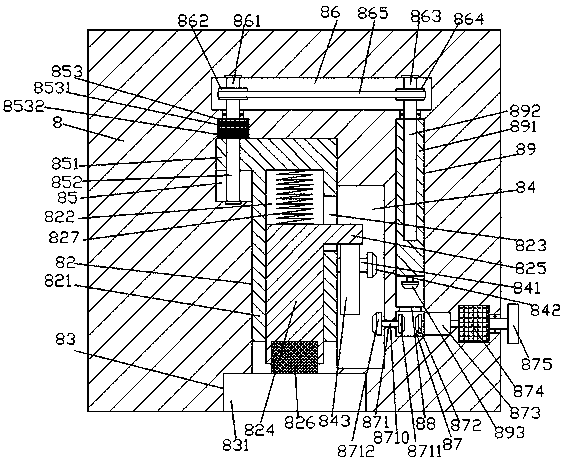

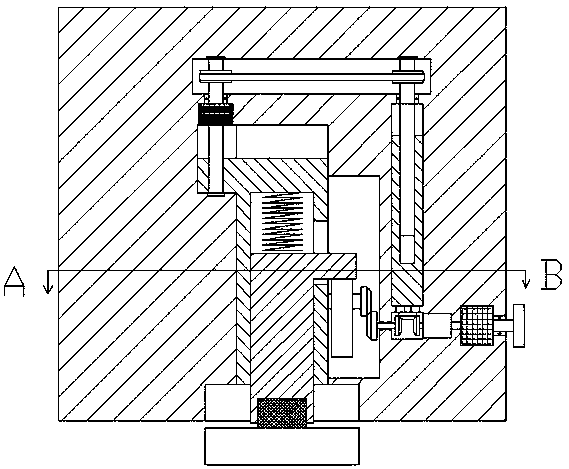

[0020] Such as Figure 1-Figure 4 As shown, a pollution-free construction equipment of the present invention includes a base body 8 and a runner 81 that is rotatably arranged at the bottom of the base body 8 , and the bottom surface of the base body 8 is provided with a containing groove 83, and the inside of the containing groove 83 The top wall is connected with an upwardly elongated longitudinal chute 82, and the substrate 8 above the longitudinal chute 82 is provided with a left and right elongated first transmission cavity 86, and the right side of the longitudinal chute 82 is The inner wall is connected with a second transmission cavity 84, and the top of the inner wall on the left side of the longitudinal chute 82 is connected with a first guide chute 85, and the top of the first guide chute 85 is connected with the first transmission cavity. The bottom of the elongated end on the left side of 86 is opposite, and the first guide chute 85 is provided with a first screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com