Raisin air-drying room

A raisin and heating room technology, applied in the field of drying room, can solve the problems of long cycle and affecting the drying of raisins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

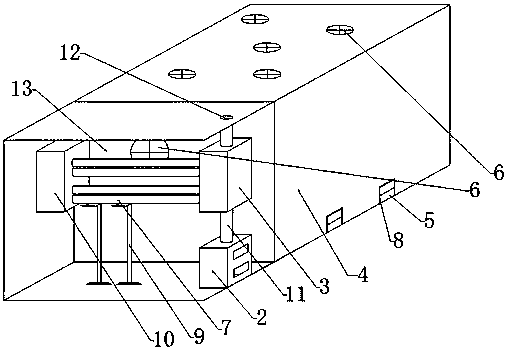

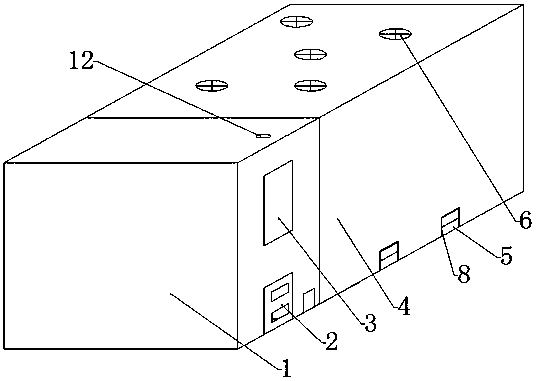

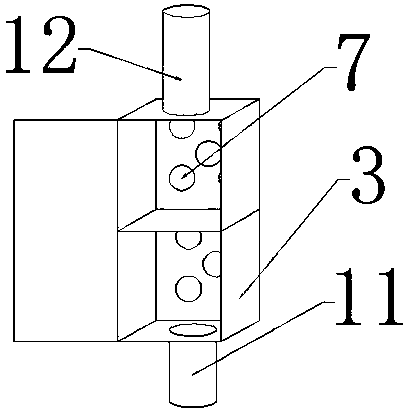

[0020] Example 1, such as Figure 1~Figure 6 As shown, a raisin drying room includes a heating room 1 and a drying room 4, a heating furnace 2 is arranged on the lower right side of the heating room, a heating box 3 is arranged directly above the heating furnace 2, and an exhaust gas is connected above the heating box 3 Discharge pipe 12, exhaust gas discharge pipe 12 leads to the roof, so that the exhaust gas is discharged from the roof, a hot air reversing box 10 is arranged on the left side of the heating box 3, a ventilation pipe 11 is arranged between the heating furnace 2 and the heating box 3, and the heating A heating pipe 7 is arranged between the box 3 and the hot air reversing box 10, a support frame 9 is arranged below the heating pipe 7 close to the hot air reversing box 10, a baffle is arranged in the middle of the heating box 3, and a side of the heating box 3 is provided There is a through hole connecting the heating pipe 7, a door is arranged on the side oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com