A method for measuring surface defects of linear guide rail

A technology for linear guides and defects, which is applied in the field of measuring concave and convex defects on the surface of linear guides, can solve problems such as difficulty in repairing, difficulty in determining accurate positions, etc., and achieves the effects of simple and reasonable method, elimination of errors, and improvement of detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

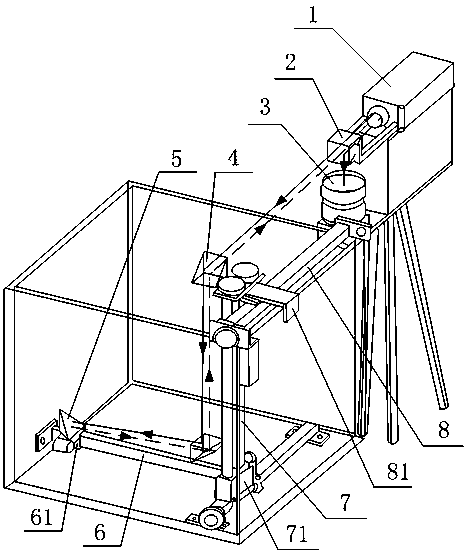

[0015] Such as figure 1 As shown, a method for measuring surface defects of a linear guide rail includes a laser interferometer 1 , a beam splitter 2 , a camera 3 , a 45-degree right-angle prism 4 and a corner cube 5 . The measured X guide rail 8 is fixed on the right side of the upper end surface of the radiotherapy water tank. The measured X guide rail 8 is movably socketed on the X carrier 81 . The X stage 81 is fixed with the Y guide rail 7 to be tested. The upper end of the tested Y guide rail 7 is fixed to the X carrier 81, and the lower end extends into the bottom of the inner cavity of the radiotherapy water tank. The measured Y guide rail 7 is movably socketed on the Y carrier platform 71 . The Z guide rail to be tested is fixed on the Y stage 71 . The Z guide rail under test is socketed on the Z stage 61 . The Z stage 61 is connected to the scanning probe base (not shown in the figure). figure 1 In the figure, the left end of the figure is the original point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com