Method and device for detecting defect of surface of steel rail based on data processing

A defect detection and data processing technology, applied in measurement devices, optical devices, optical testing of defects/defects, etc., can solve problems such as reducing the density and speed of train traffic, increasing the maintenance cost of railway trunk lines, and increasing the possibility of train derailment. , to achieve the effect of improving measurement accuracy, improving detection efficiency and accuracy, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

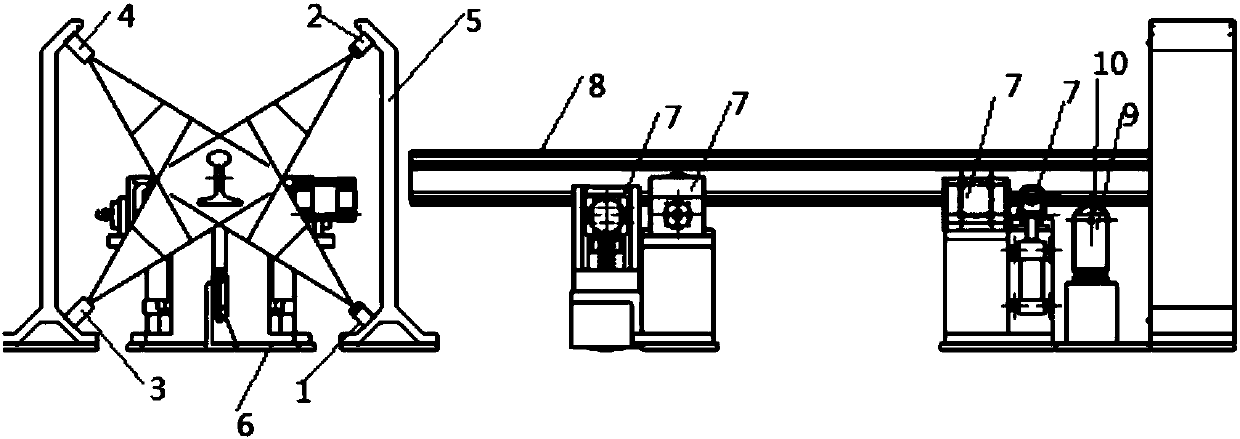

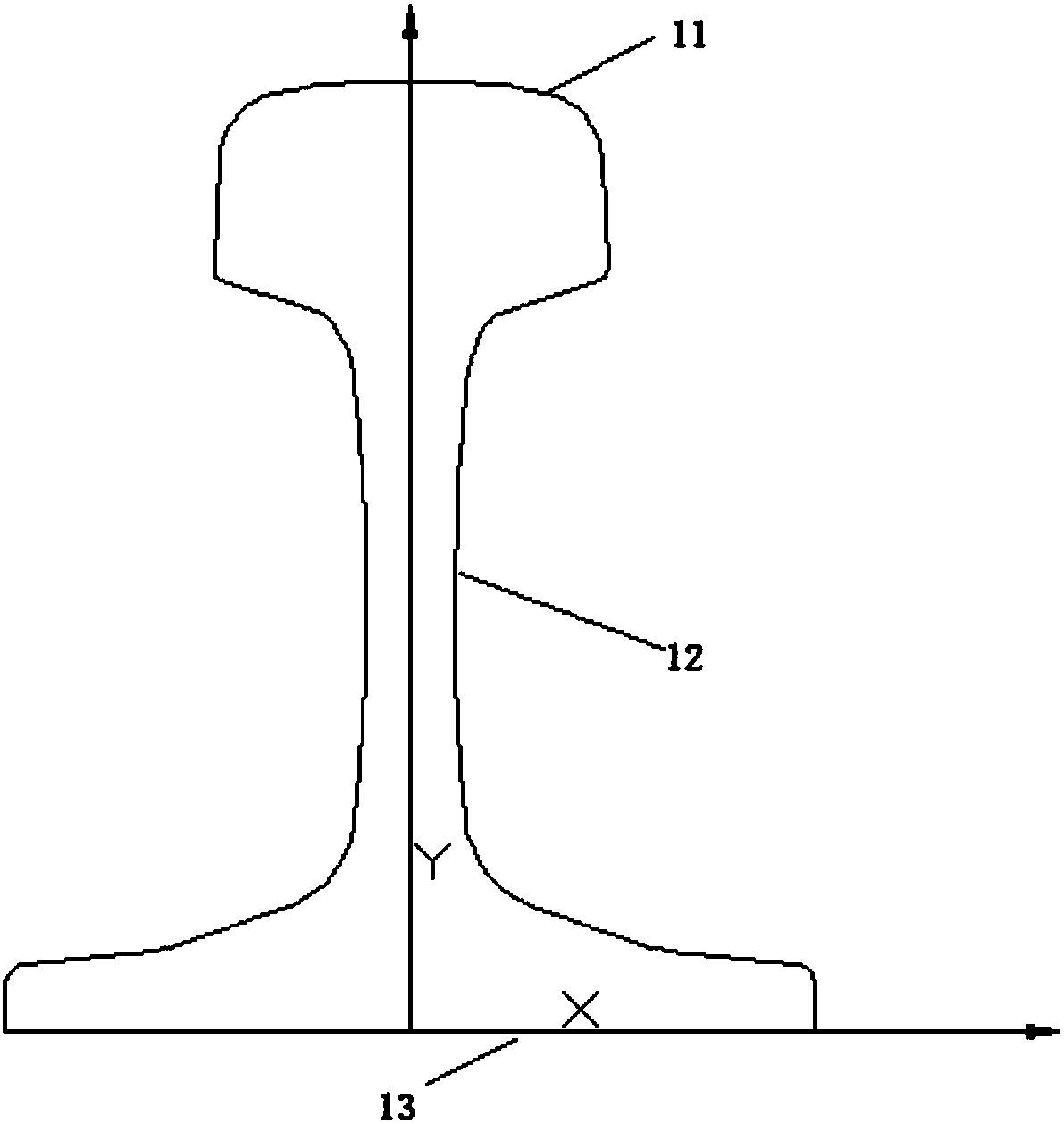

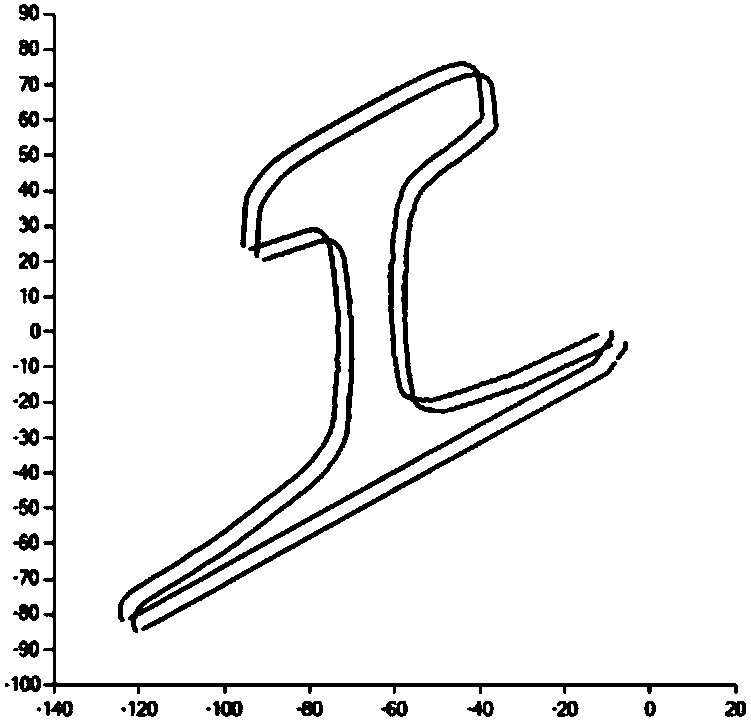

[0034] The invention relates to a method and device for detecting defects on the surface of rails based on data processing. The device includes four sensors, sensor bracket (5), base (6), track conveyor roller (7), steel rail (8), encoder bracket (9) and encoder (10), and the four sensors are respectively installed on the sensor At the four inner corners of the bracket, the Z-axis of each sensor forms an included angle of 45° with the horizontal direction and intersects at one point, and rail conveying rollers are fixed on the base to support and convey the rails. The method is to stitch together and calibrate the images collected by the four sensors, then stitch each frame of data collected by each sensor into a complete profile according to the calibration value, and remove the overlapping data, draw a standard profile with CAD and calculate its Segmented function, the translation of the scanning profile coincides with the center of gravity of the standard profile. When ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com