Double voltage sampling circuit of battery charging and discharging device

A technology of charging and discharging equipment and sampling circuit, applied in the field of dual-voltage sampling circuit, can solve the problem of battery overcharge or overdischarge, and achieve the effect of solving charging explosion, abnormal voltage protection, practical and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

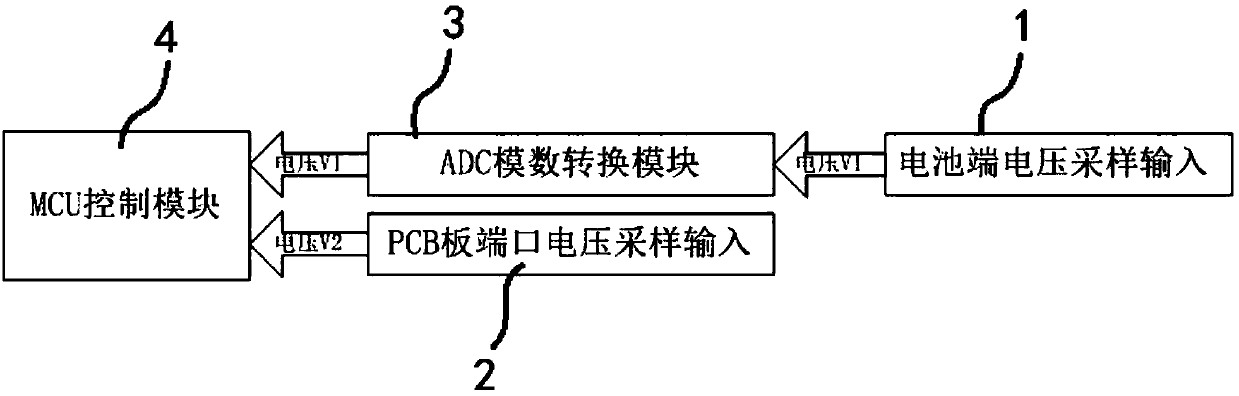

[0020] Such as figure 1 As shown, a dual-voltage sampling circuit for battery charging and discharging equipment includes: a battery terminal voltage sampling input module 1, a PCB port voltage sampling input module 2, an ADC analog-to-digital conversion module 3, and an MCU control module 4. The battery terminal voltage The sampling input module 1 is connected to the ADC analog-to-digital conversion module 3, and the ADC analog-to-digital conversion module 3 is connected to the MCU control module 4, and the analog signal is converted into a digital signal by the ADC analog-to-digital conversion module 3, and then sent to the MCU control module 4 The PCB port voltage sampling input module 2 is directly connected to the ADC analog-to-digital conversion input port of the MCU control module 4 . Signal transmission is performed between the ADC analog-to-digital conversion module 3 and the MCU control module 4 through the SPI communication protocol.

[0021] The working method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com