Control rod drive mechanism and method for nuclear reactor

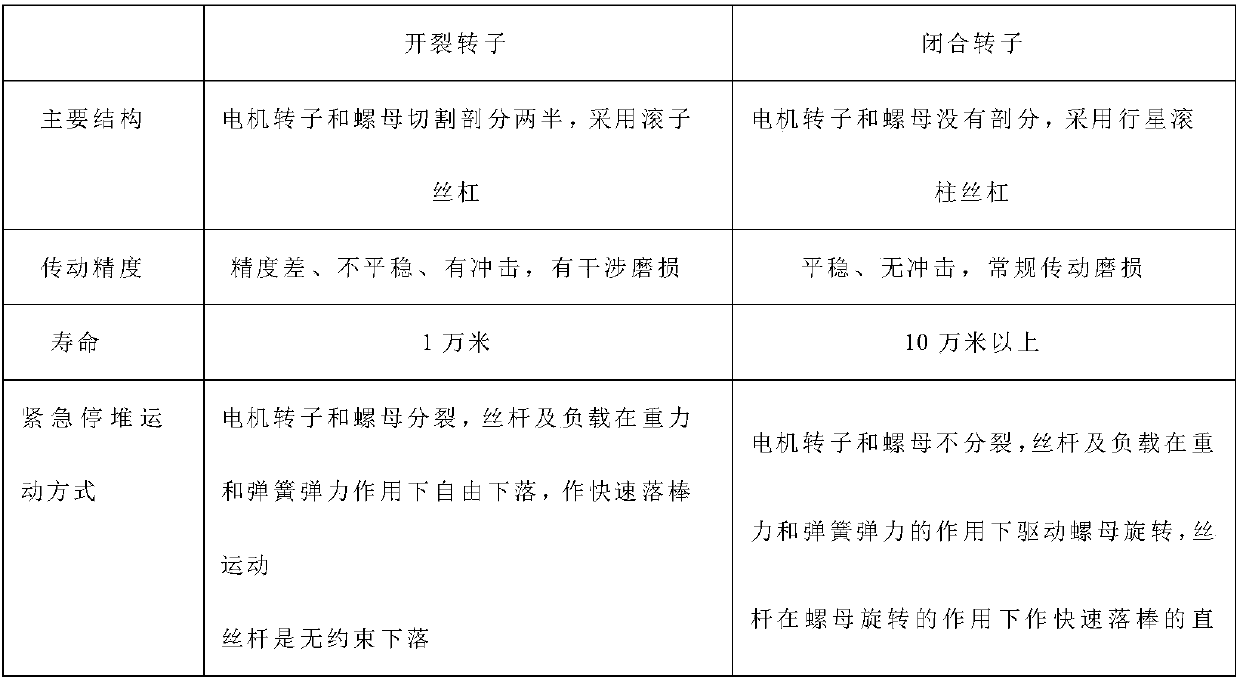

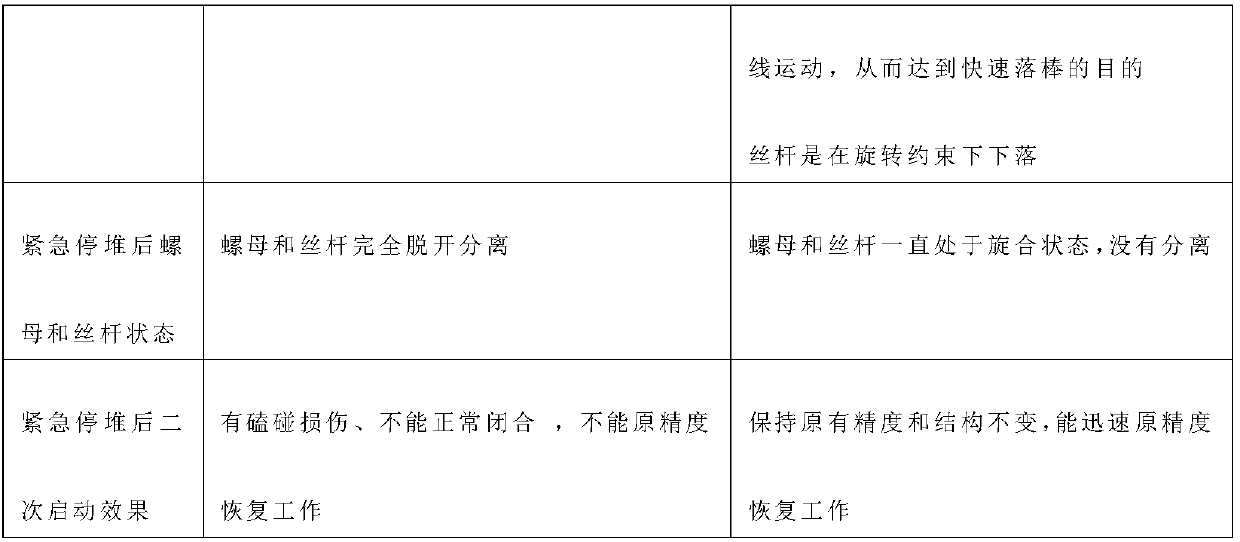

A technology for nuclear reactors and driving mechanisms, applied in the control of nuclear reactions, reactors, nuclear engineering, etc., can solve the problems of low reliability, short life, unable to close normally with original precision, etc., and achieve the effect of improving safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the nuclear reactor control rod driving mechanism and method provided by the present invention will be described in detail below with reference to the accompanying drawings.

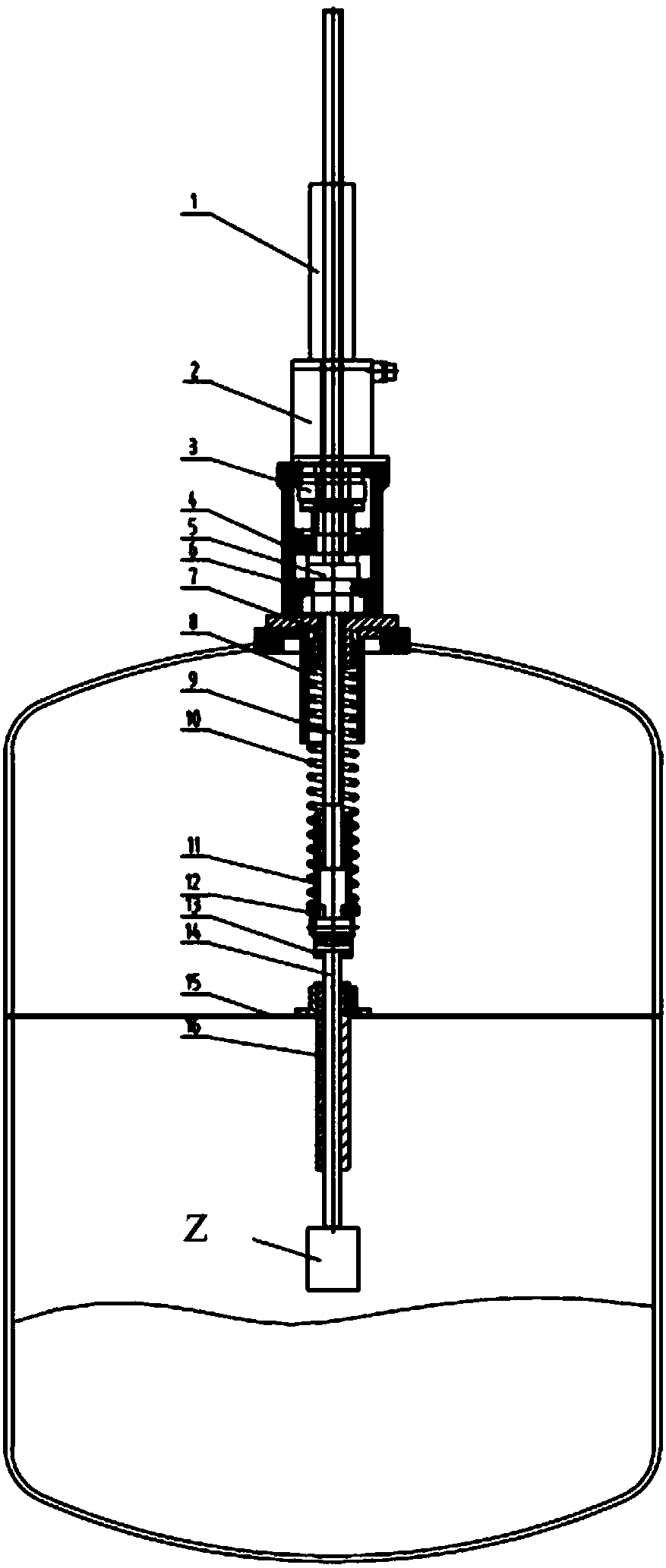

[0026] Such as figure 1 As shown, the nuclear reactor control rod driving mechanism includes a position sensor 1, a reluctance motor 2, a coupling 3, a fixed support seat 4, a planetary roller screw nut 5 and a planetary roller screw screw 9, a bearing 6, a spring Upper holder 7, spring outer guide sleeve 8, spring 10, spring inner guide sleeve 11, spring lower support base 12, connecting sleeve 13, guide rod 14, upper support plate 15 and guide cylinder 16.

[0027] The position sensor 1 is installed on the reluctance motor 2, and the position sensor 1 forms a closed loop with the rotary encoder on the reluctance motor 2, and feeds back the position information to the control system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com