Automatic lock nut machine

A nut machine and automatic lock technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve positioning, avoid no-load phenomenon, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, features and effects of the automatic nut locking machine proposed according to the present invention are described in detail below.

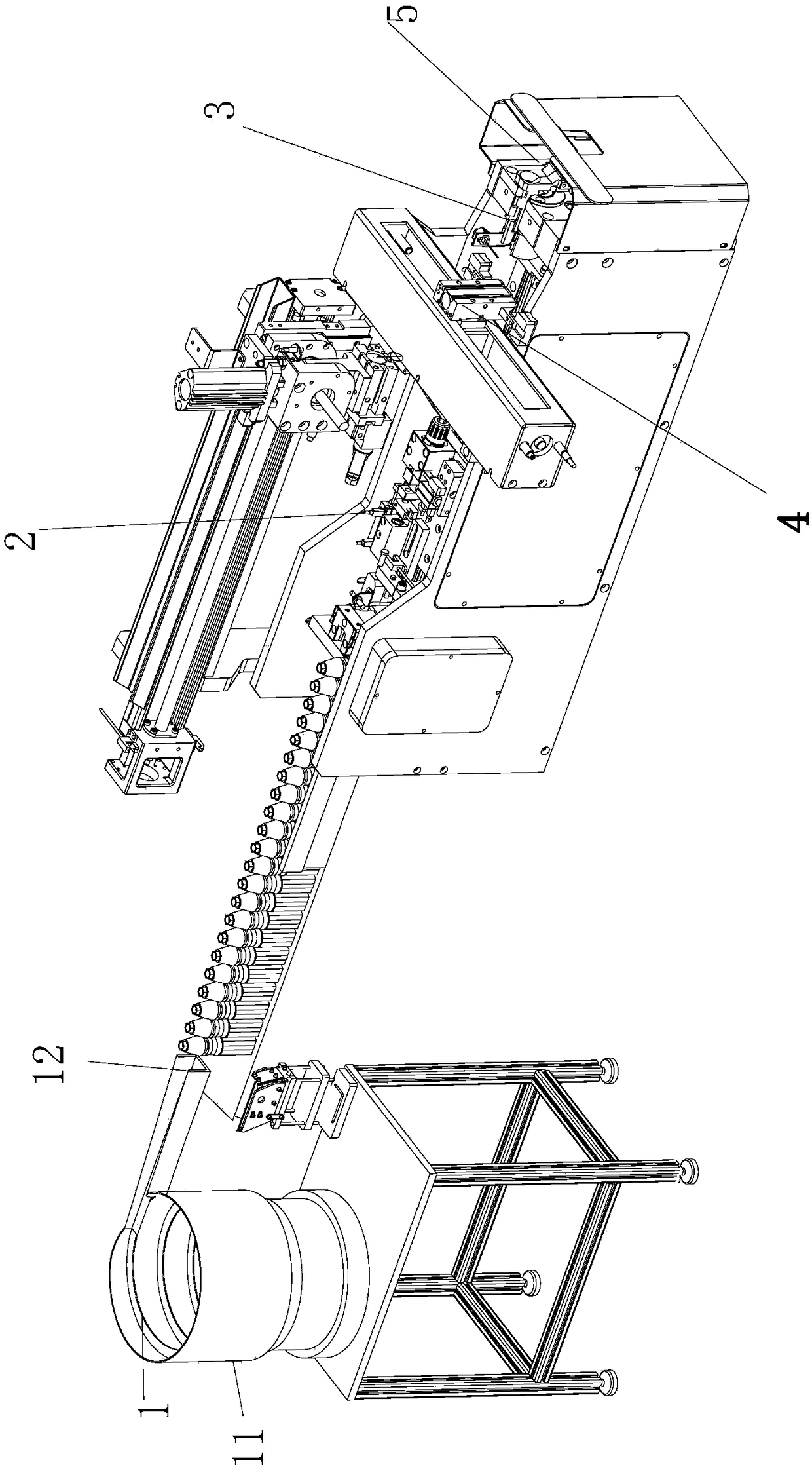

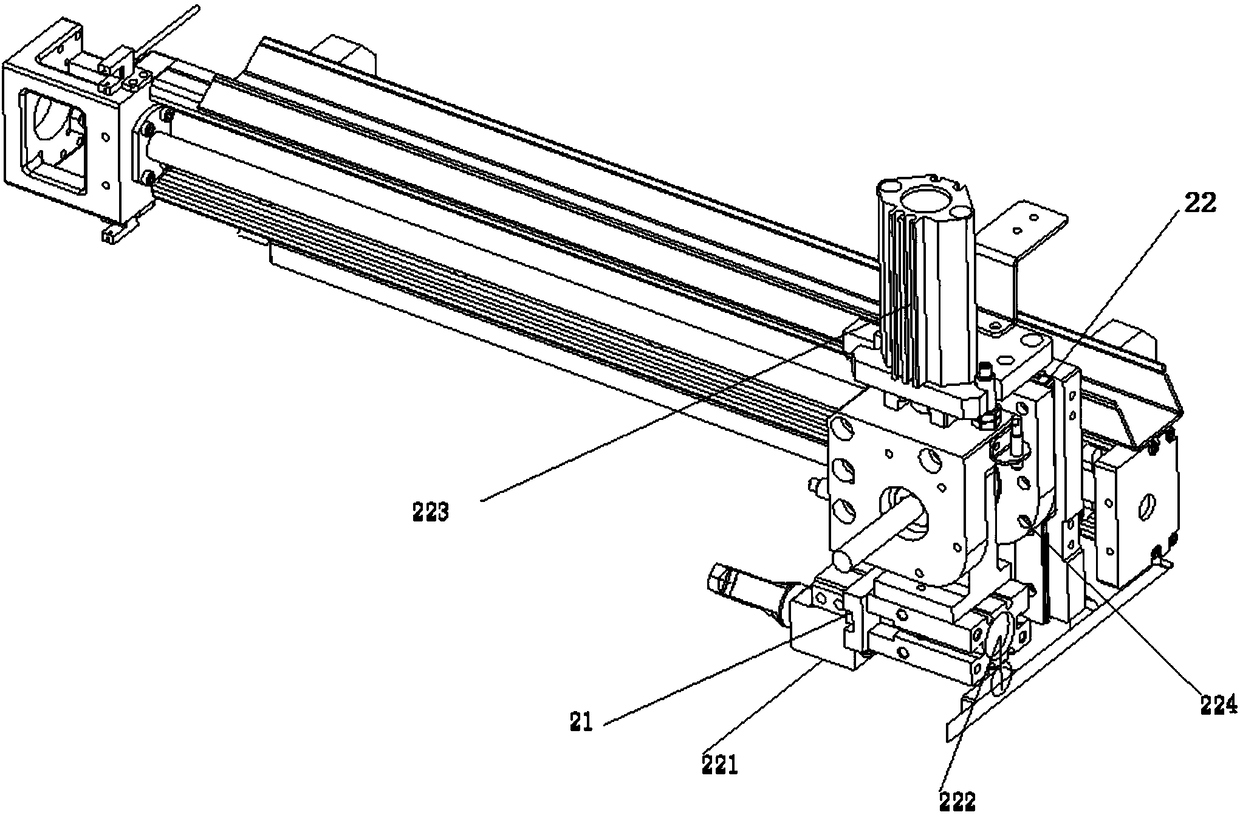

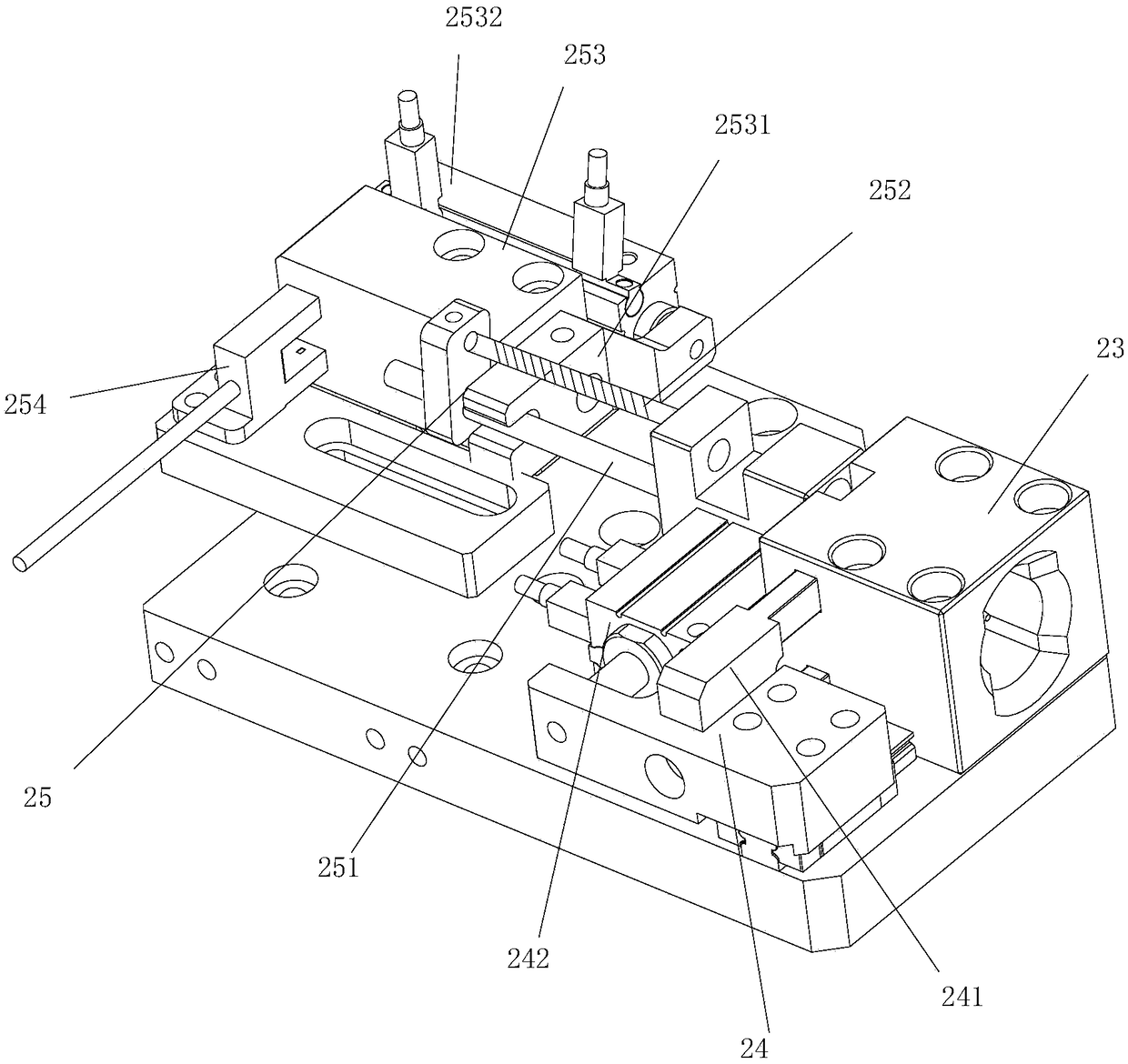

[0051] Such as figure 1 As shown, the present invention discloses an automatic nut lock machine, comprising a first feeding device 1, a second feeding device 5, a transport device 2, a locking device 3 and a feeding device 4, wherein the first feeding device Used to transport the nuts to be tightened to the first fixed station, the transport device 2 is connected to the first feeding device 1, and is used to transport the nuts at the first fixed station to the locking device 3, and the second upper The material device 5 is connected with the locking device 3, and is used to transport the cable to the locking device 3, and the locking device 3 is used to complete the tightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com