Full-automatic cutting equipment

A fully automatic, cutting technology, applied in metal processing and other directions, which can solve the problems of missing cutting knives and cumbersome operation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

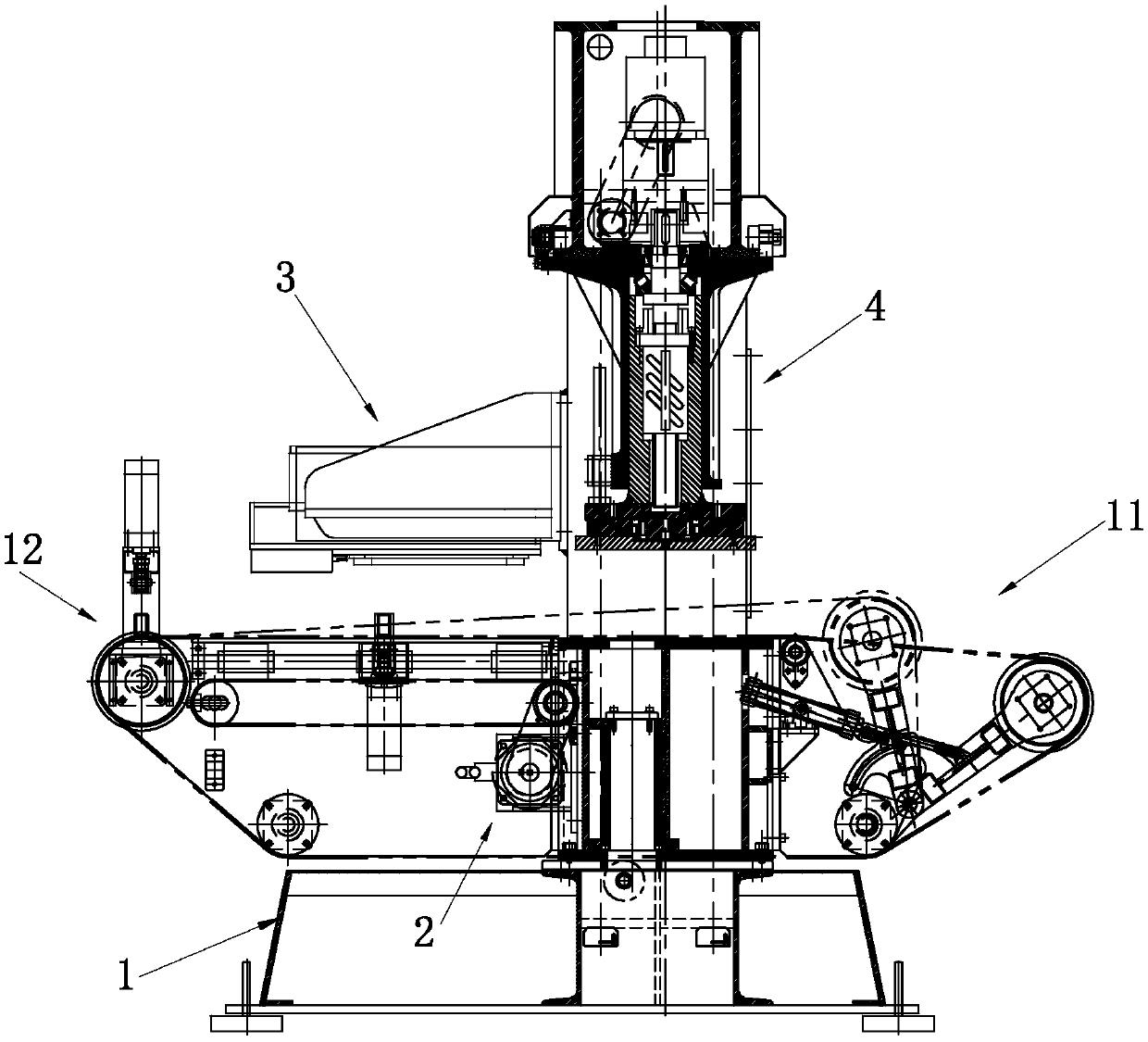

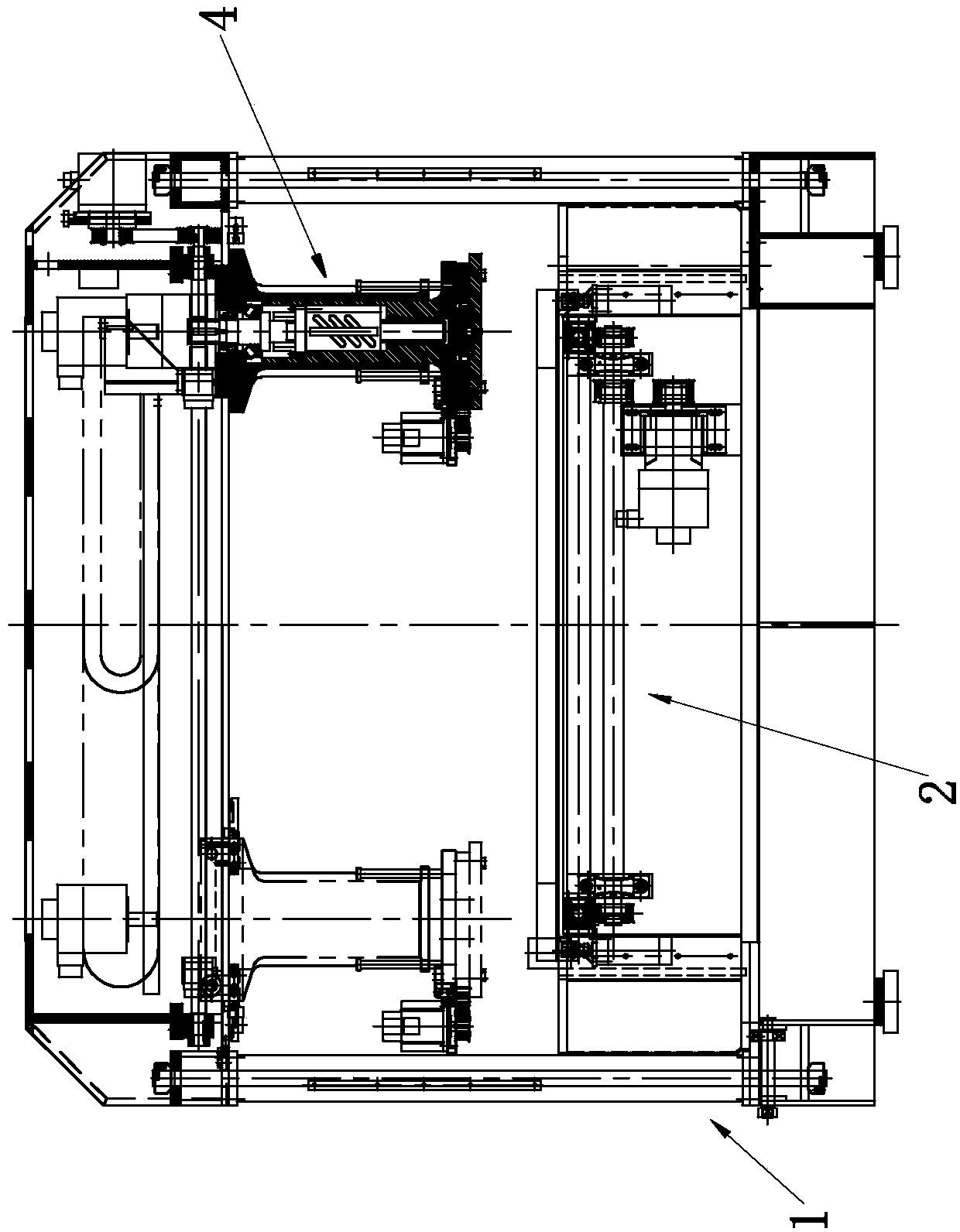

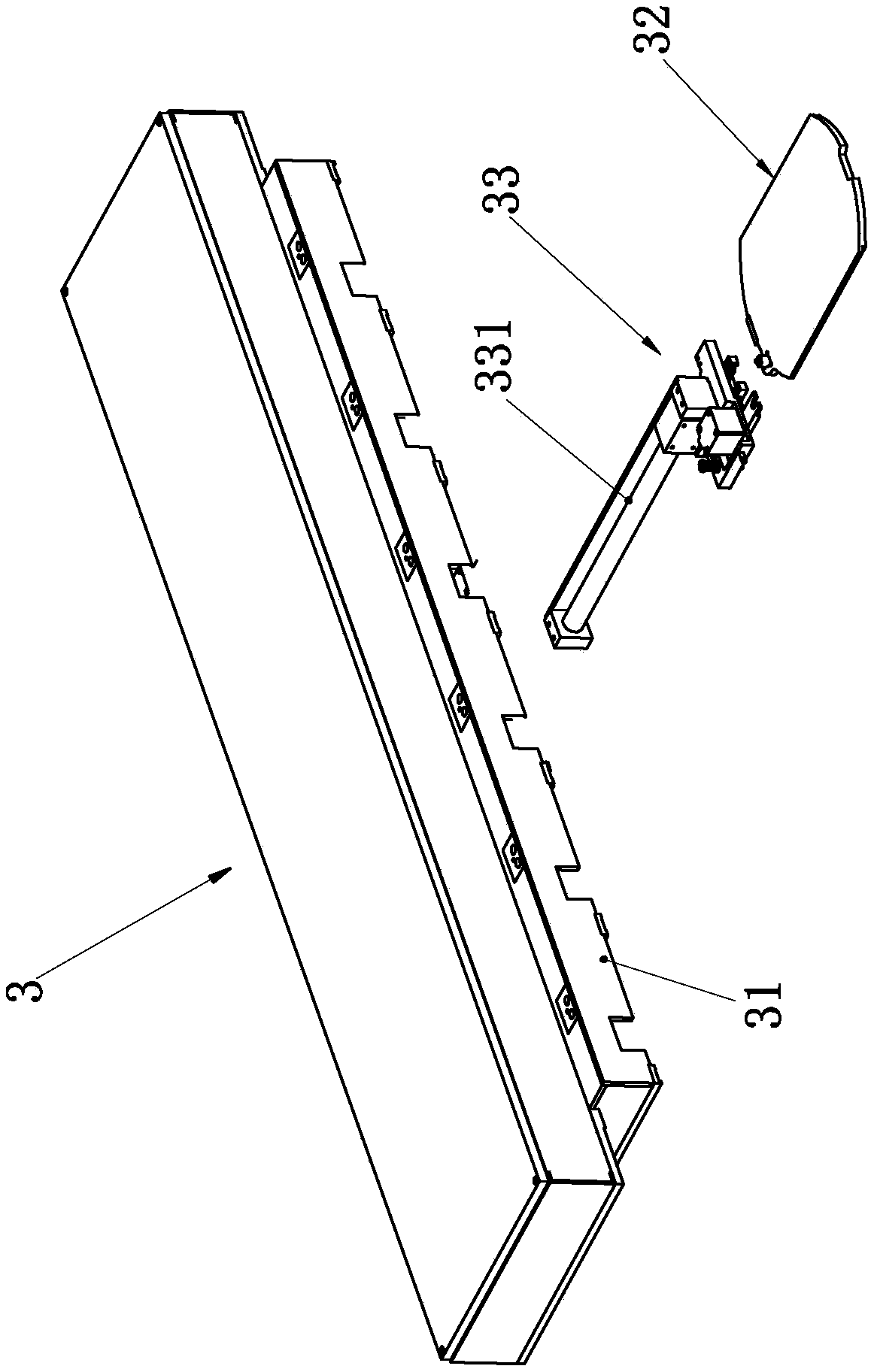

[0030] like figure 1 — Figure 9 A full-automatic cutting device shown includes a body 1, a feed end 11 and a discharge end 12 arranged on the body 1, and a cutting device for cutting is provided between the feed end and the 11 discharge end 12 And the conveying device 2 that will output the material that has been cut to the discharge end 12, the cutting device includes a cutter assembly 3 and a cutting assembly 4, and the cutter assembly 3 includes a knife seat 31 fixed on the body 1, a set A number of die mounting plates 32 for the cutting knife to be installed in the knife seat 31 and a number of groups corresponding to the number of die mounting plates 32 that can be taken out from the knife seat 31 or placed in the knife seat 31 Extraction mechanism 33; Cutting assembly 4 comprises the support 41 that organic body 1 is fixed, the driving source 42 erected on the support 41, the lifting seat 43 linked with the driving source 42 and is connected with the lifting seat 43 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com