Die-casting aluminum alloy capable of being subjected to anodic oxidation

A technology of casting aluminum alloy and anodizing, applied in the field of die-casting aluminum alloy, can solve the problems of discoloration, poor die-casting performance, low yield rate, etc., and achieve the effect of high yield rate, good coloring effect and strong die-casting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

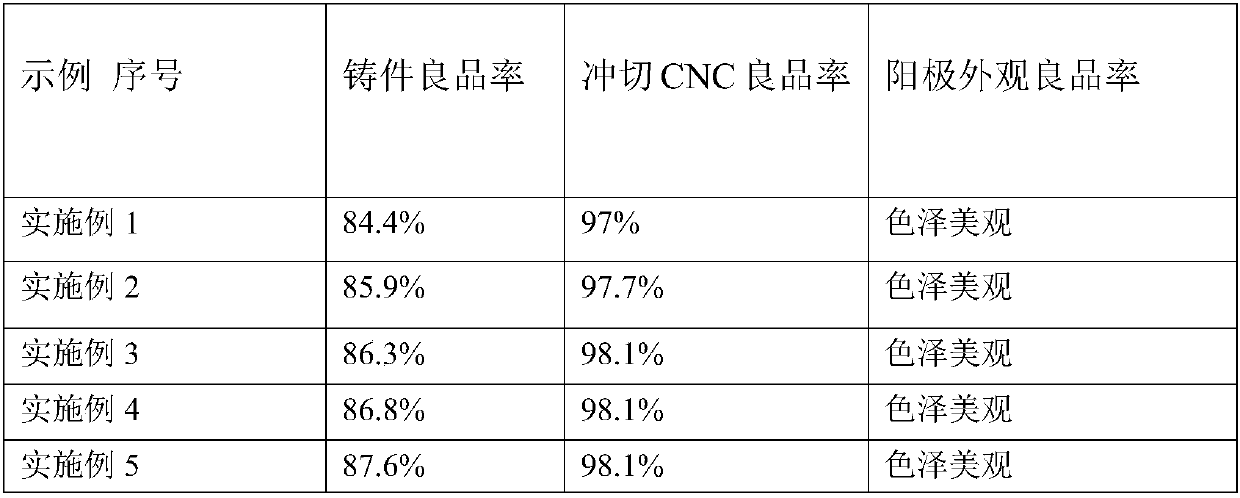

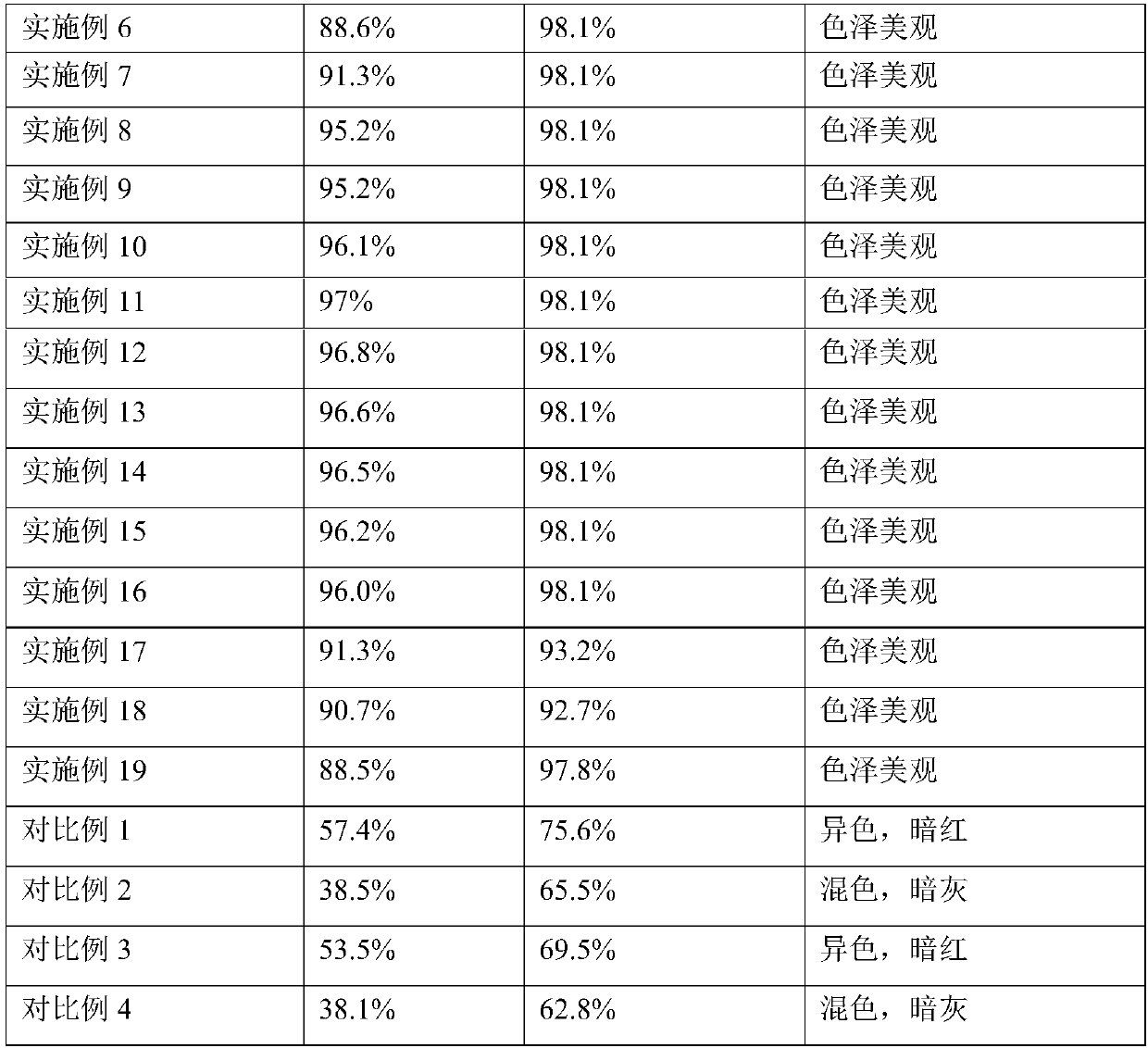

Examples

Embodiment 1

[0017] The anodizable die-casting aluminum alloy is composed of the following components in mass percentage: Al: 98.5%; Fe: 0.39%; Mn: 0.70%; Si: 0.40%; and the sum of impurities: 0.01%.

Embodiment 2

[0019] The anodizable die-cast aluminum alloy is composed of the following components by mass percentage: Al: 98.2%; Fe: 0.48%; Mn: 0.82%; Si: 0.49%; and the sum of impurities: 0.01%.

Embodiment 3

[0021] The anodizable die-casting aluminum alloy is composed of the following components by mass percentage: Al: 98.29%; Fe: 0.50%; Mn: 0.70%; Si: 0.50%; and the sum of impurities: 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com