High-sealing secondary high-pressure pump

A high-sealing, high-pressure pump technology, used in the field of air pumps, can solve problems such as insufficient pressure and poor sealing, and achieve the effects of high air pressure, good sealing, and balanced force in the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

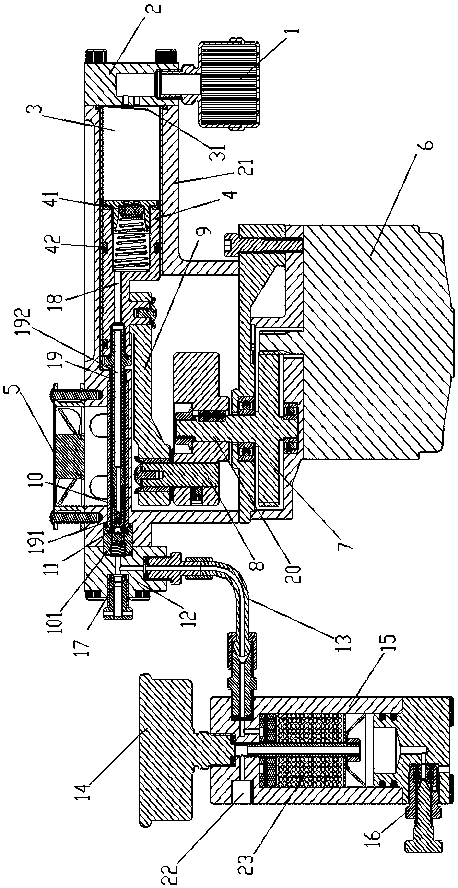

[0017] see figure 1 As shown, the technical solution adopted in this specific embodiment is: a high-seal two-stage high-pressure pump, which includes a motor 6, a noise reduction filter 1 and a high-pressure filter 15, and a reduction box 7 is arranged in front of the motor 6. There is an output shaft 20 inside the gearbox 7, one end of the output shaft 20 is connected to a crankshaft 8, one end of the crankshaft 8 is connected to a connecting rod 9, one end of the connecting rod 9 is connected to the crankshaft 8, and the other end is connected to a primary piston 4. One end of the primary piston 4 is provided with a primary cylinder 3, and the other end is connected with a secondary piston rod 19. One end of the primary cylinder 3 is provided with a primary cylinder head 2, and the periphery of the primary cylinder 3 is fixed There is a cylinder seat 21, the first-stage cylinder head 2 is connected to the muffler filter 1, the second-stage piston rod 19 is sealed and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com