A high-temperature strain measurement method for eliminating the effect of out-of-plane displacement

A technology of out-of-plane displacement and high-temperature strain, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem that the calibration accuracy has a great influence on the measurement accuracy, the experimental device is complicated, and the operation is very difficult and other problems, to achieve the effect of wide field of view, compact equipment structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

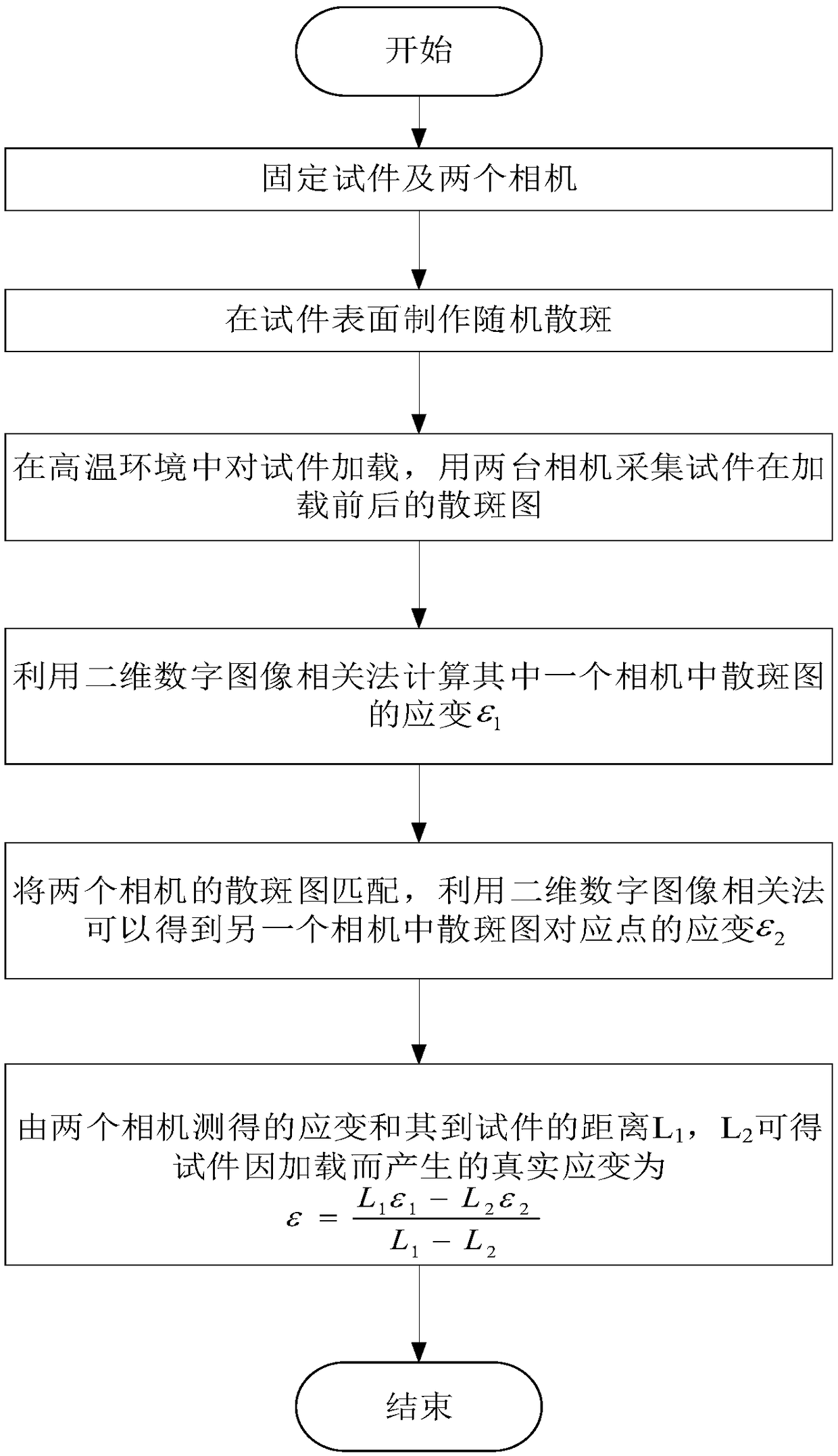

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

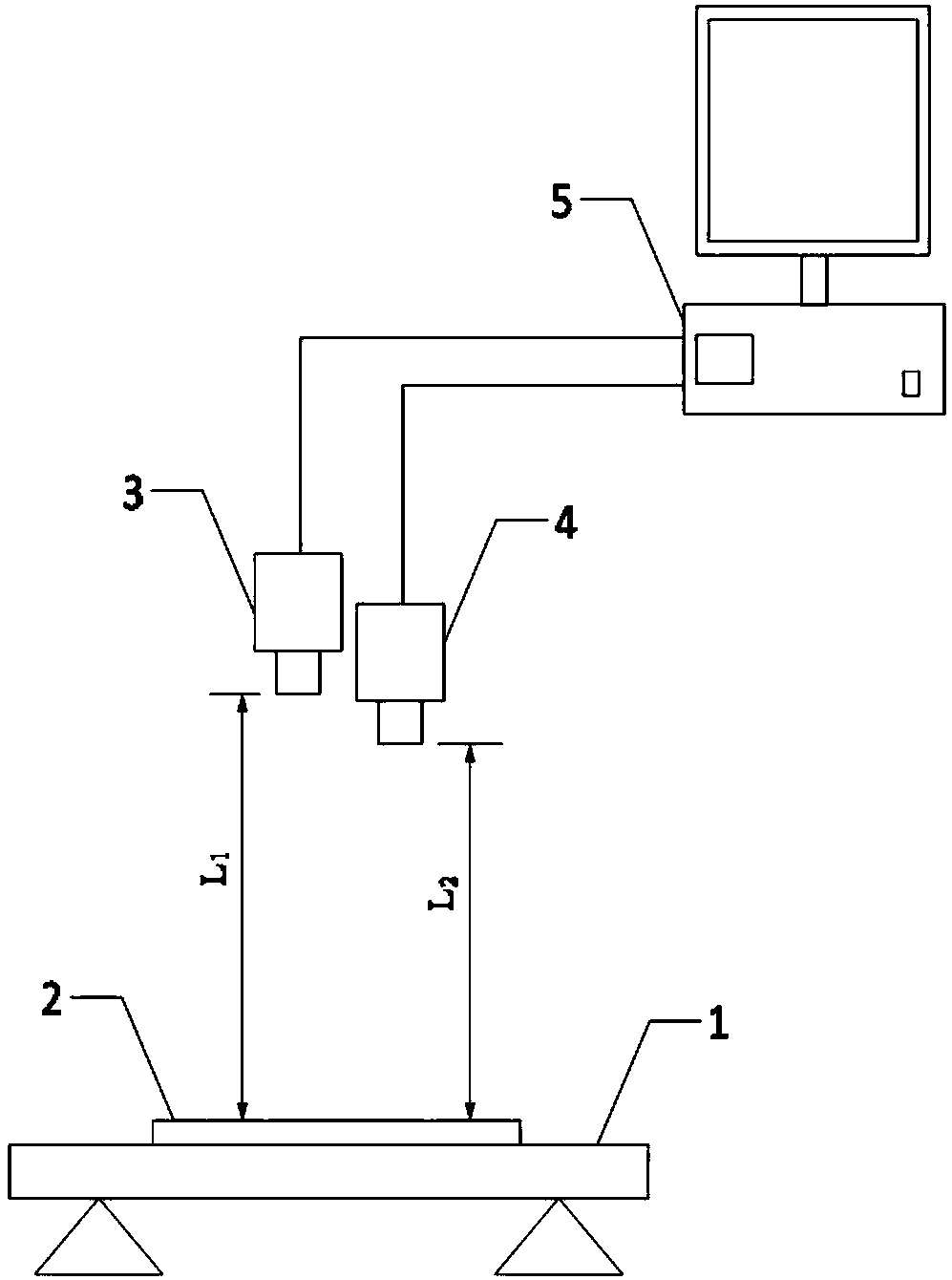

[0023] Such as figure 1 As shown, the high-temperature strain measurement device for eliminating the influence of out-of-plane displacement in this embodiment includes a high-temperature loading platform, a test piece, two cameras, and a computer containing a calculation program.

[0024] The test piece in this embodiment is made of aluminum alloy, and the camera pixels are 1024*1024. The specimen was fixedly mounted on a high-temperature loading platform, and random speckles were made on the surface of the specimen by using high-temperature-resistant materials. Fix two cameras, the object distance L of camera A 1 is 500 mm, the object distance L of camera B 2 The lens plane of the two cameras should be roughly parallel to the plane of the speckle pattern, and the angle between the lens planes of the two cameras and the plane of the speckle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com