A Reverse 3D Reconstruction and Solid Modeling Method of Skeleton Structure of Pavement Material

A skeleton structure, three-dimensional reconstruction technology, applied in the field of construction engineering, can solve the problems of limited size, high use cost, inability to describe the three-dimensional spatial information of the skeleton structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

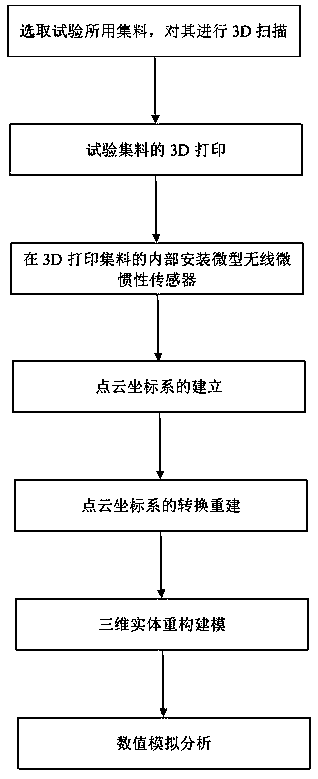

[0033] Embodiment 1: as Figure 1-4 As shown, a reverse three-dimensional reconstruction and solid modeling method of the skeleton structure of pavement materials. This test uses asphalt mixture to prepare AC-16C asphalt mixture. The selected gradation is shown in Table 1:

[0034] Table 1

[0035]

[0036] According to the passing rate of 1 to 3 grades, the aggregates are screened out for mixture blending, the oil-stone ratio is 5.5%, and the mineral powder is 3% inside. Aggregate: limestone;

[0037] The selected coarse aggregate is the aggregate with a sieve hole of 2.36mm or more, and then proceed to the following steps:

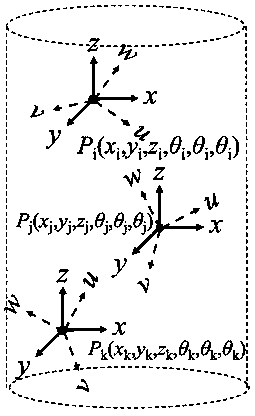

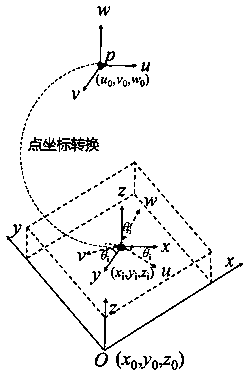

[0038] A. Three-dimensional scanning of the test aggregate; use a non-contact three-dimensional laser scanner to scan the test coarse aggregate particles to obtain a high-density point cloud reflecting the surface feature information of the aggregate; use the reverse engineering software Imageware to analyze the three-dimensional point cloud data Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com