Electric vehicle thermal management control method and system

A thermal management, electric vehicle technology, applied in electric vehicles, battery/fuel cell control devices, circuits, etc., can solve the problems of unintelligent control, reduced passenger driving experience, loud noise, etc., to improve energy saving efficiency and avoid adjustment difficulties or can not adjust, reduce the effect of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

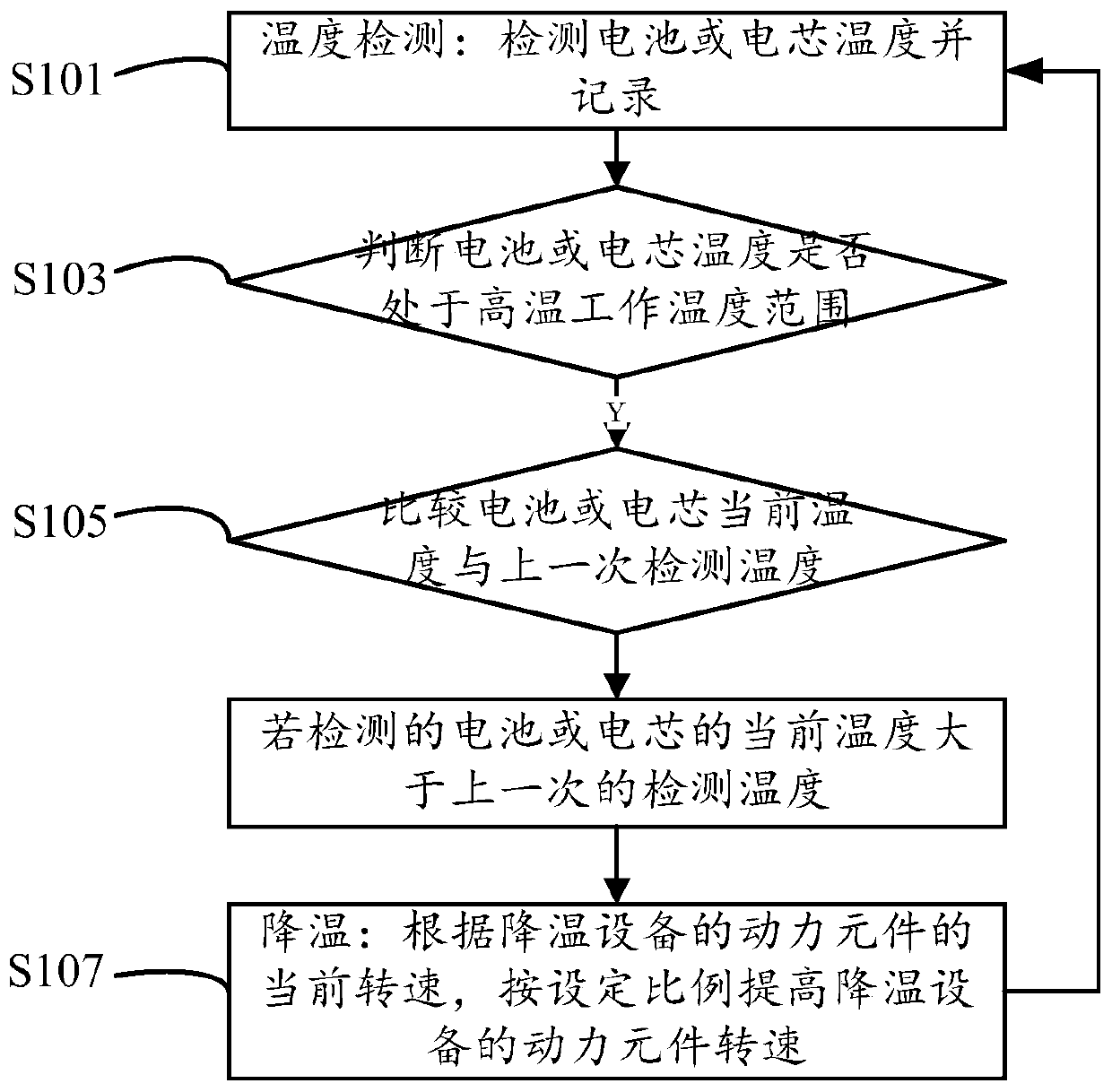

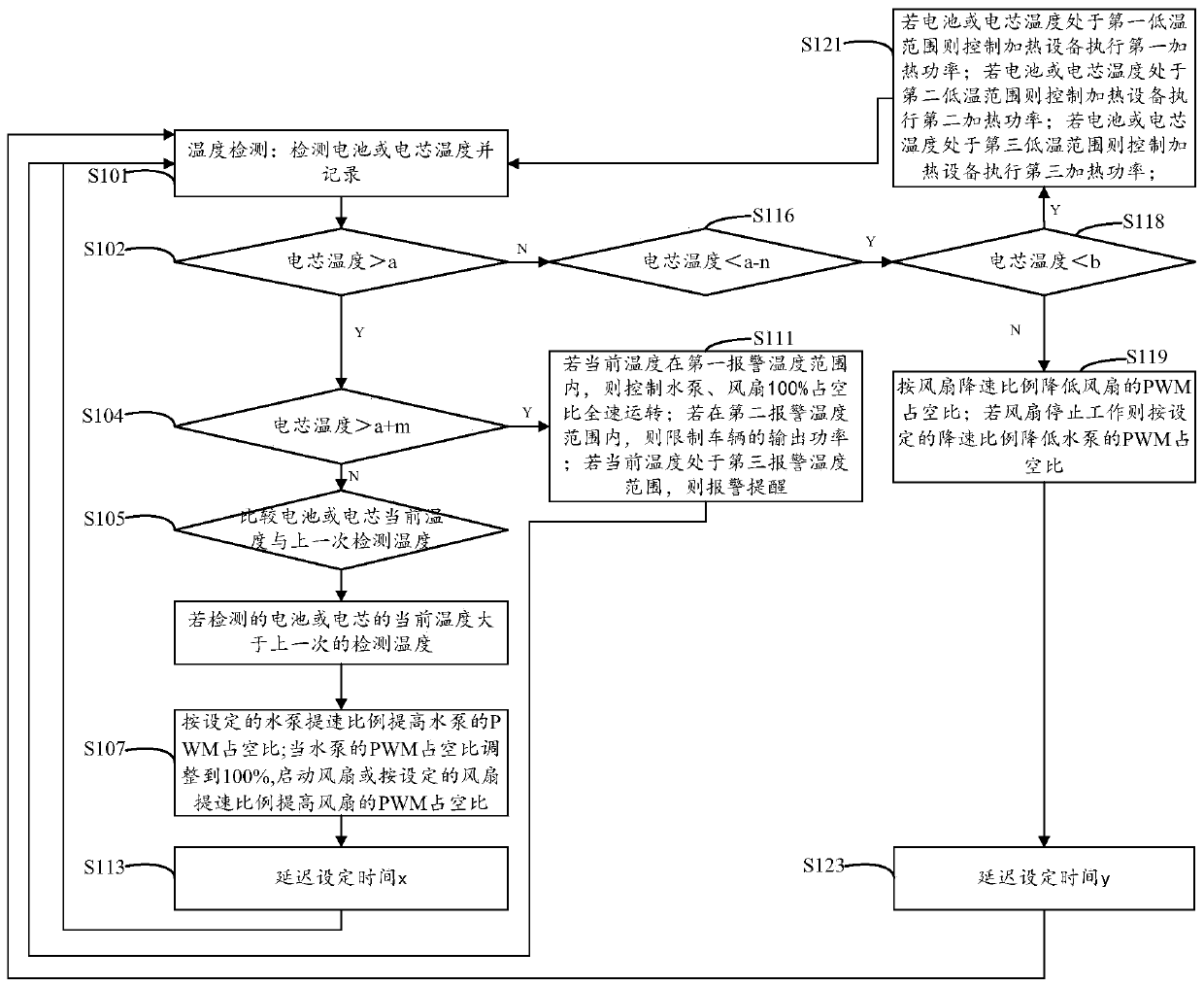

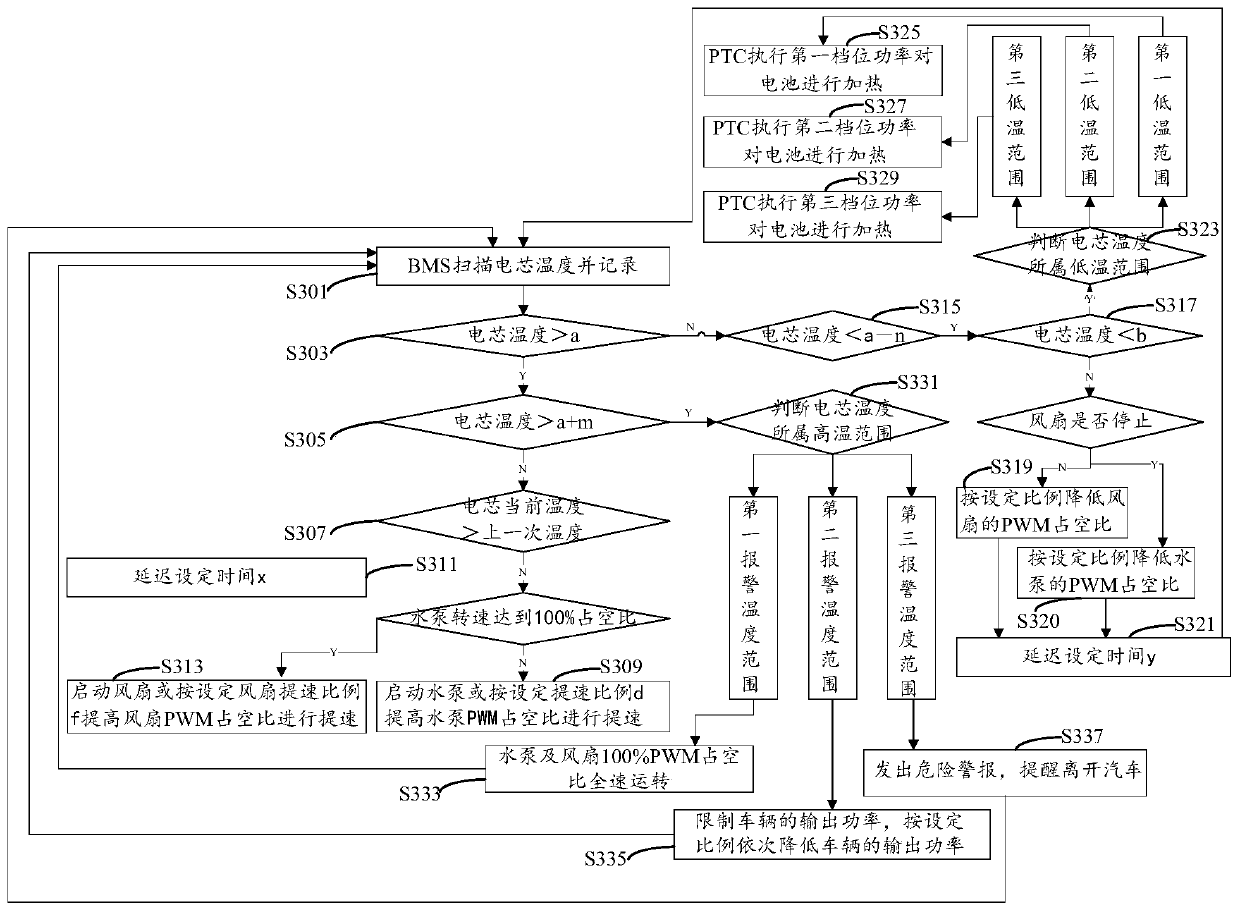

[0070] like figure 1 As shown, a thermal management method for an electric vehicle according to an embodiment of the present invention includes the following steps:

[0071] Step S101, temperature detection: the temperature of the battery or cell is detected and recorded,

[0072] Step S103, temperature judgment: judging whether the temperature of the battery or cell is within the high temperature working temperature range,

[0073] If the high temperature operating temperature range is not exceeded, execute

[0074] Step S105, temperature comparison: compare the current temperature with the previous temperature,

[0075] If the current temperature is greater than the previous temperature, execute

[0076] Step S107, cooling: according to the set ratio, proportionally increase the rotational speed of the power element of the cooling device;

[0077] Repeat the above steps until the power element of the cooling device is running at full speed.

[0078] The cooling device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com