Metal part anti-rust oiling device and method

A technology for parts and metals, applied in the field of anti-rust oiling devices for metal parts, which can solve the problems of waste, unresolved, excessive oil stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

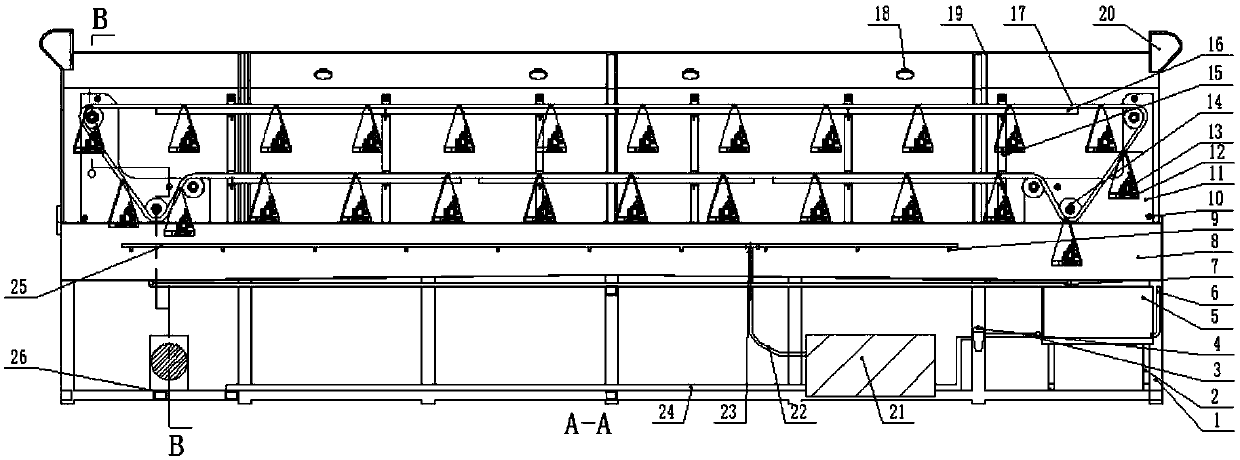

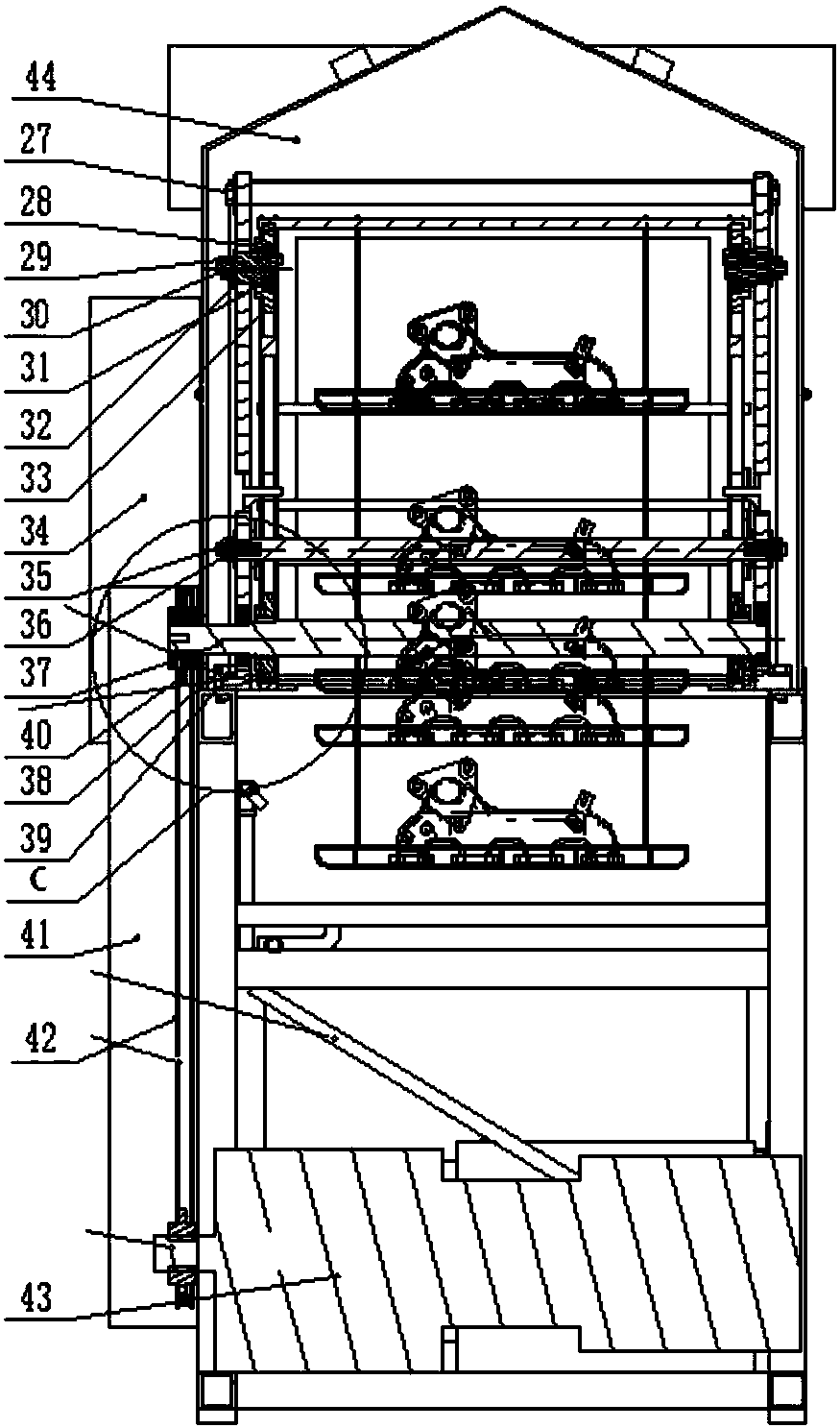

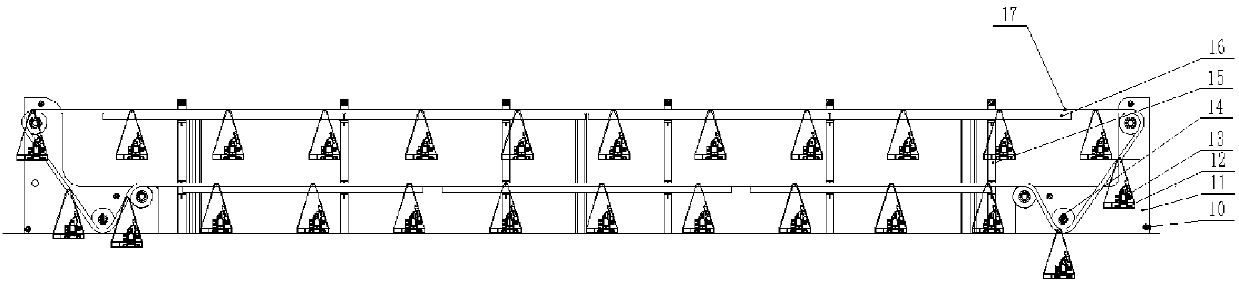

[0050] The specific implementation of this embodiment is as follows:

[0051] Such as figure 1 As shown in -4, the antirust and oiling device for metal parts provided in this embodiment includes a frame 1, an oil atomization system, a product delivery system, an oil mist chamber, a control system, and a turbulence and condensation device 18; The upper part of the frame 1 is equipped with an oil atomization system, which is used to spray oil mist on the anti-rust product; the oil mist chamber is set on the frame 1, including the upper seal set on the top of the frame 1 The chamber 44 and the lower sealed chamber 8 arranged on the top of the frame 1, the upper sealed chamber 44 and the lower sealed chamber 8 are correspondingly arranged up and down, and the upper sealed chamber 44 is detachably connected with the lower sealed chamber 8, and the upper sealed chamber 44 is detachably connected with the lower sealed chamber 8. The sealed chamber 44 can be opened or closed as requi...

Embodiment 2

[0061]The antirust and oiling method for metal parts provided in this embodiment mainly uses the above-mentioned antirust and oiling device for metal parts. The specific steps are as follows. Step A: input antirust oil into the oil mist chamber through the oil atomization system , the anti-rust oil is atomized by high pressure, and under the action of the turbulence and condensing device 18 in the upper sealed chamber 44, the high-pressure atomized oil mist is controlled in the sealed oil mist chamber, and a certain concentration of oil mist is formed and full movement; step B: the product to be processed is transported to the closed oil mist chamber through the product delivery system, and the product 12 to be processed is continuously moved in the closed chamber, so that the inner and outer surfaces of the product 12 to be processed are fully in contact with the Oil mist contact; Step C: After a period of time, a thin layer of oil film is formed on the inner and outer surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap