A treatment device for sulfur and nitrogen waste gas

A treatment device and technology for waste gas, applied in the field of biological desulfurization and denitrification treatment, can solve the problems of increasing the pressure loss of a trickling filter tower, speeding up the rate of mass transfer, affecting the deodorization effect, etc., achieving simple structure, improving biological activity, and improving treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

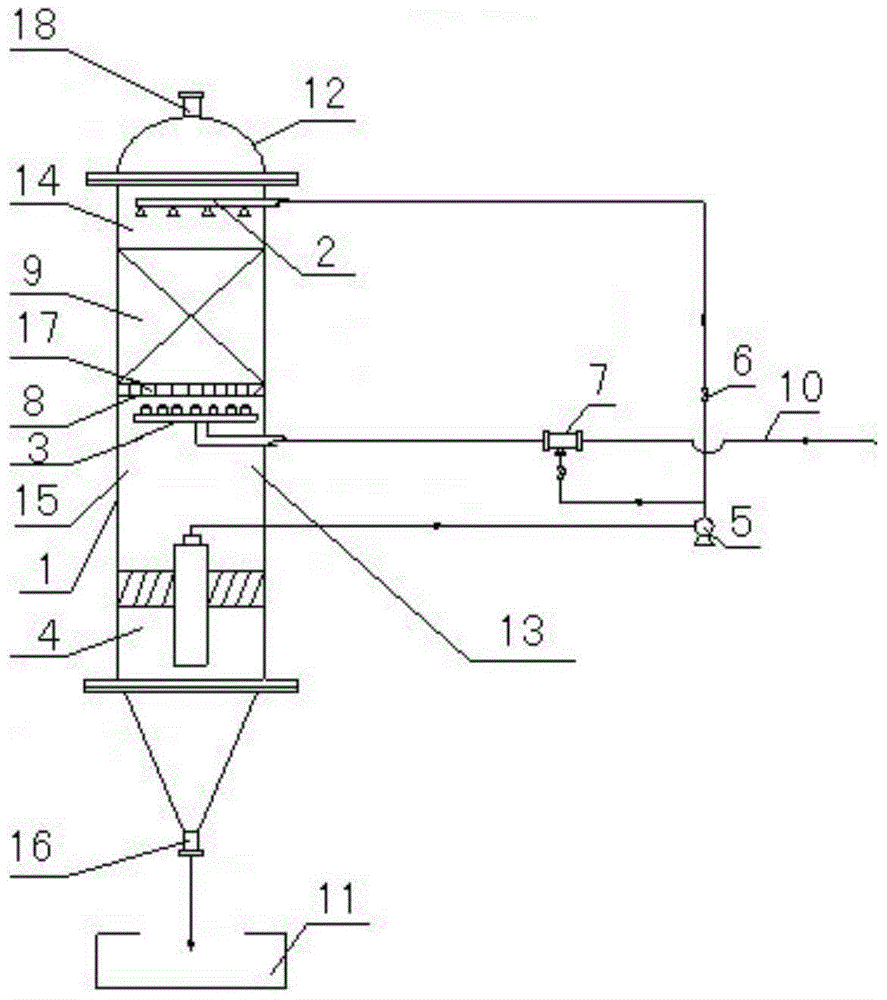

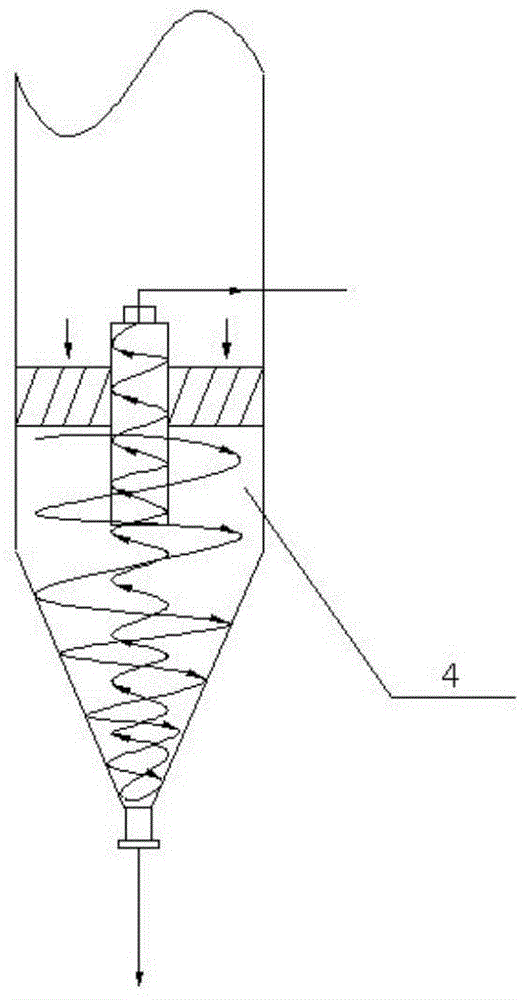

[0021] This embodiment provides a treatment device for waste gas containing sulfur and nitrogen, including a biological trickling filter tower 1 . The inner diameter of the biological trickling filter tower 1 is 500 mm to 550 mm, and the inner diameter of the biological trickling filter tower 1 within the above range can make the degradation rate of the sulfur-containing and nitrogen-containing waste gas reach 99%. The biological trickling filter tower 1 is composed of an upper cone cylinder 12 , a cylinder body 13 and a cyclone separation device 4 . The upper cone 12 is fixed on the top of the cylinder 13 and fixed by a flange. The cyclone separation device 4 is fixed on the bottom end of the cylinder body 13 and fixed by a flange. An exhaust port 18 is provided at the top of the upper cone 12 , and a discharge port 16 is provided at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com