Anti-rust oiling device and method for metal parts

A technology for parts and metals, which is applied in the field of anti-rust and oiling devices for metal parts, which can solve problems such as waste, unresolvable, excessive oil stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

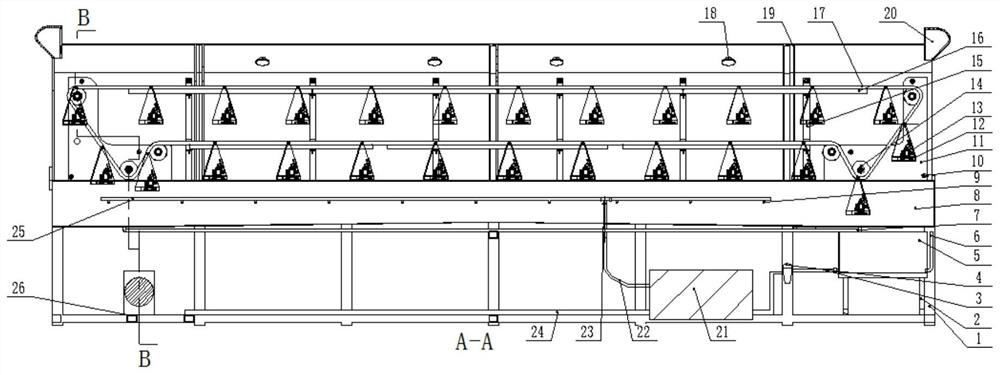

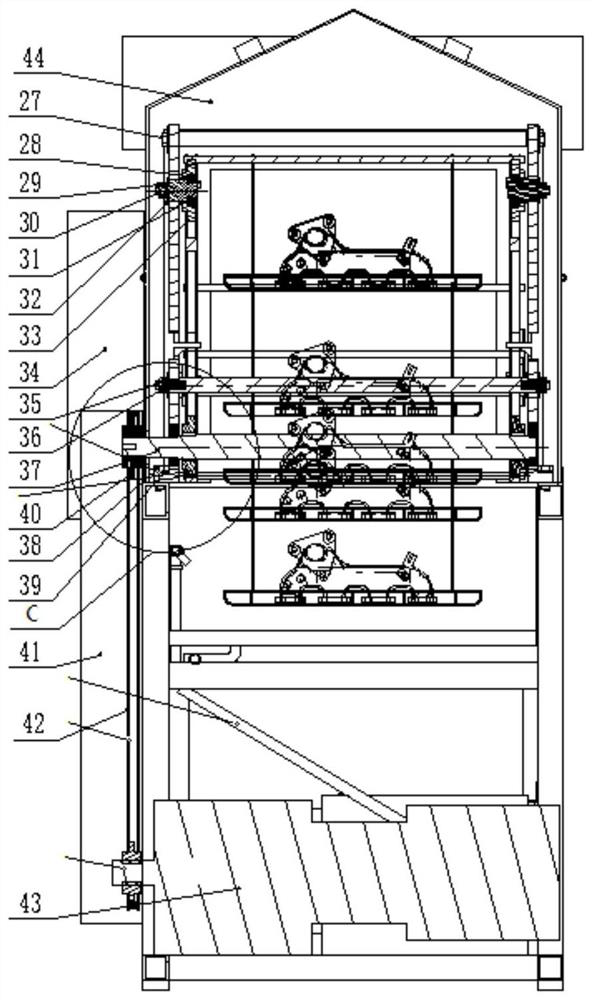

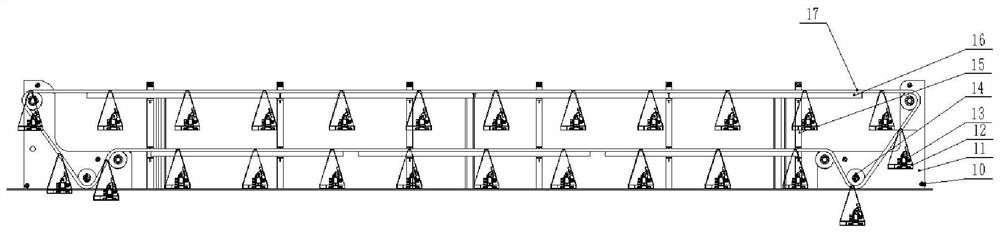

[0048] The specific implementation of this embodiment is as follows:

[0049] like figure 1 As shown in -4, the anti-rust and oiling device for metal parts provided in this embodiment includes a frame 1, an oil atomization system, a product conveying system, an oil mist chamber, a control system, and a turbulence and condensation device 18; The upper part of the rack 1 is provided with an oil atomization system, which is used to spray oil mist on the anti-rust products; the oil mist chamber is arranged on the rack 1, including the upper seal arranged on the top of the rack 1 The chamber 44 and the lower sealing chamber 8 arranged on the upper part of the rack 1 are arranged correspondingly up and down, and the upper sealing chamber 44 and the lower sealing chamber 8 are detachably connected, and the upper sealing chamber 44 and the lower sealing chamber 8 The sealing chamber 44 can be opened or closed as required, and the solution of this embodiment can be realized by the exi...

Embodiment 2

[0059]The method for rust prevention and oiling of metal parts provided in this embodiment mainly applies the above-mentioned rust prevention and oiling device for metal parts. The specific steps are as follows. Step A: Input rust-proof oil into the oil mist chamber through the oil atomization system , the anti-rust oil is atomized by high pressure. Under the action of the turbulence and condensation device 18 in the upper sealed chamber 44, the high pressure atomized oil mist is controlled in the sealed oil mist chamber and forms a certain oil mist concentration. Step B: The product to be treated is transported into the closed oil mist chamber through the product conveying system, and the product to be treated 12 is continuously moved in the closed chamber, so that the inner and outer surfaces of the product to be treated 12 are fully compatible with each other. Oil mist contact; Step C: After a period of time, a thin oil film is formed on the inner and outer surfaces of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com