Groove type wet etching device

A wet etching, groove-type technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of time-consuming and labor-intensive concentration alarm, low concentration of hydrofluoric acid, unfavorable etching process and other problems, so as to prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

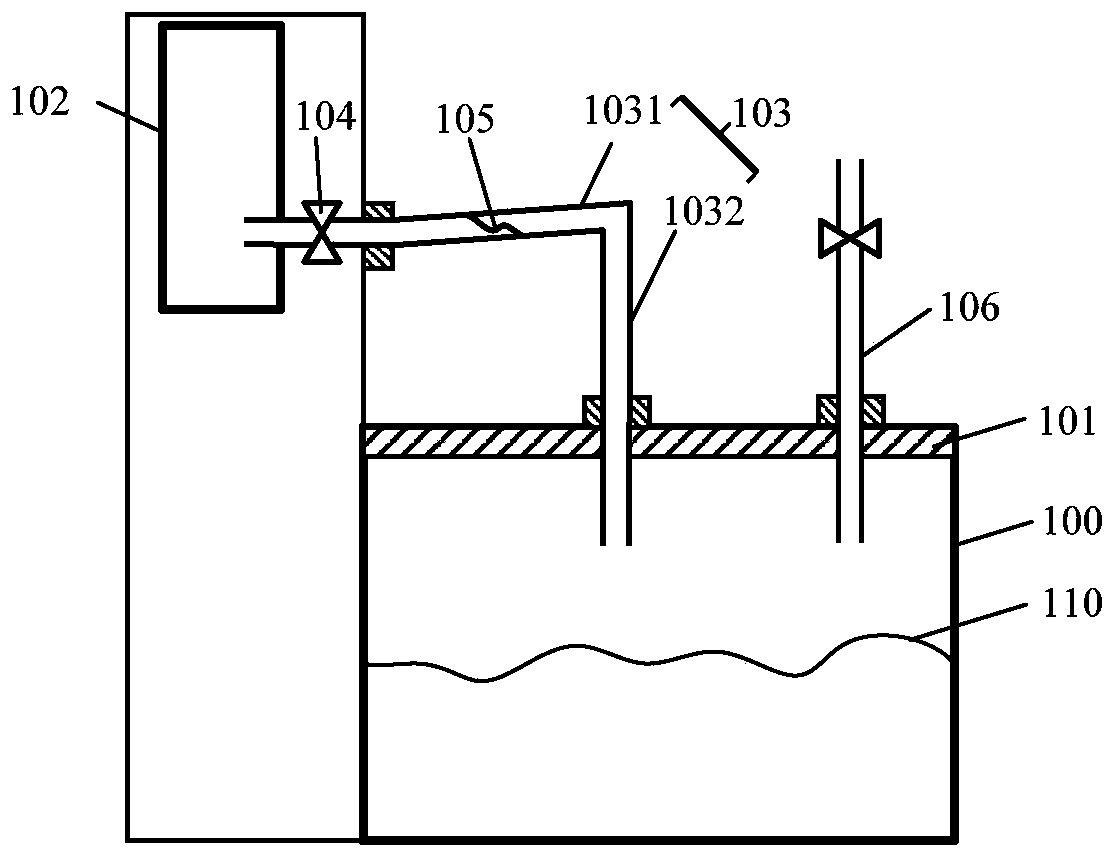

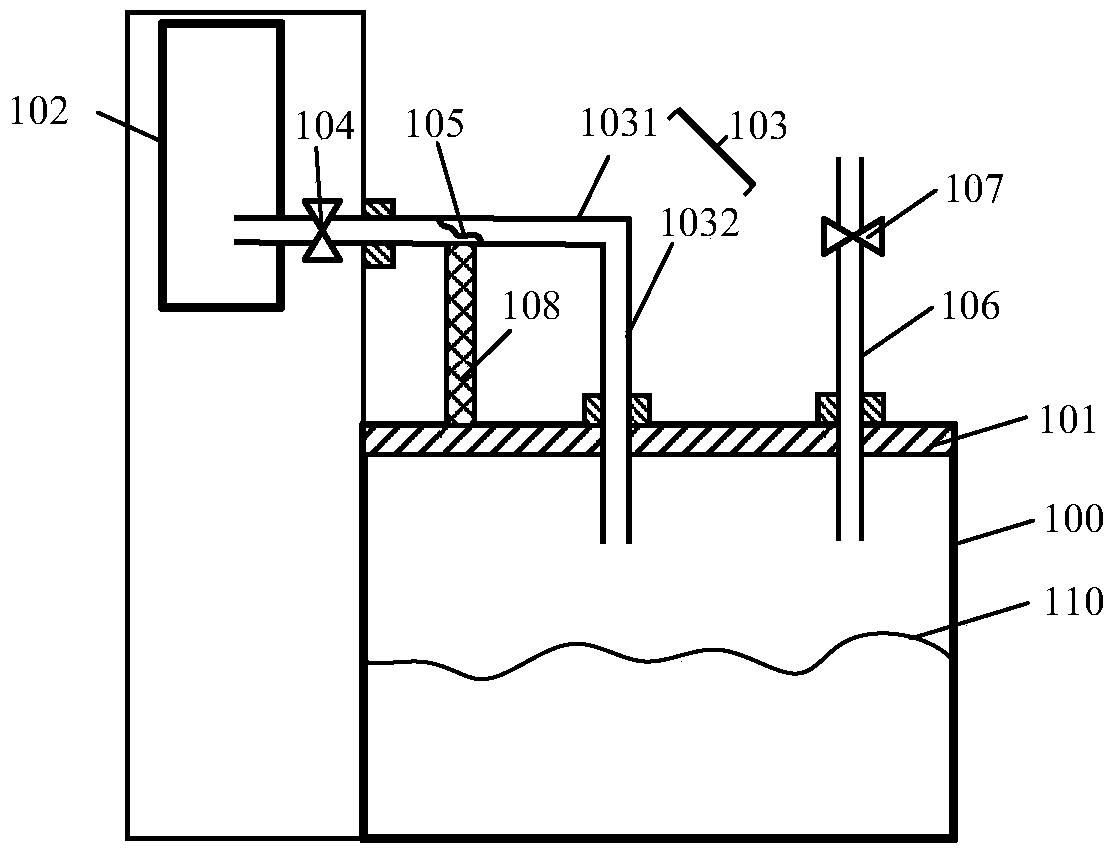

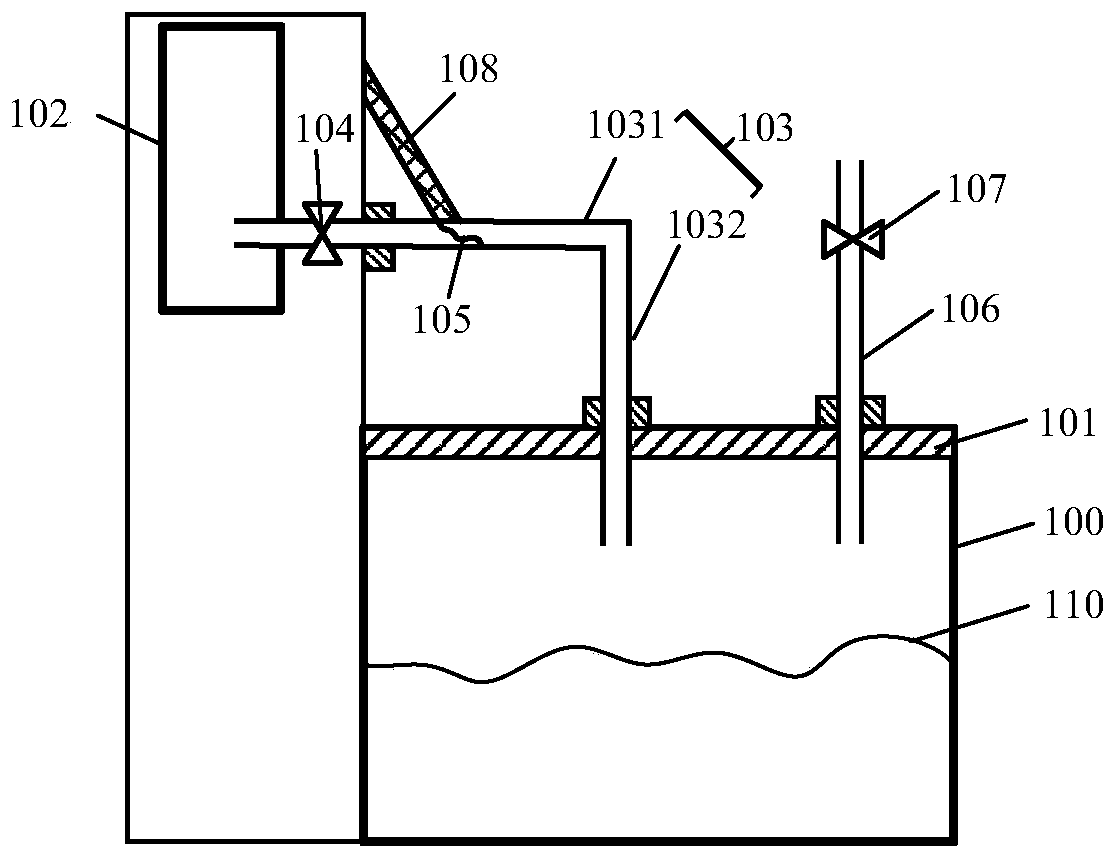

[0030] As stated in the background technology, but the aforementioned method of forming diluted hydrofluoric acid in the acid tank or process tank tends to make the concentration of the formed hydrofluoric acid low or high, which is not conducive to the etching process, and in order to eliminate the concentration Calling the police is time consuming.

[0031] The study found that when dilute hydrofluoric acid is formed in the acid bath or process bath, the bath wet etching equipment will detect the concentration of hydrofluoric acid in the acid bath or process bath. When the concentration of hydrofluoric acid in the acid tank or process tank is too high (the measured concentration value is greater than the set concentration value) or low (the measured concentration value is less than the set concentration value), a corresponding alarm will be given to stop the etching process. conduct. When such an alarm occurs, equipment personnel usually need to manually change the acid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com