Detection device for detecting yarn residues on spinning bobbins

A detection device and bobbin technology, which is applied in the field of identifying yarn residues on spinning bobbins, and can solve problems such as manual selection of spinning bobbins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

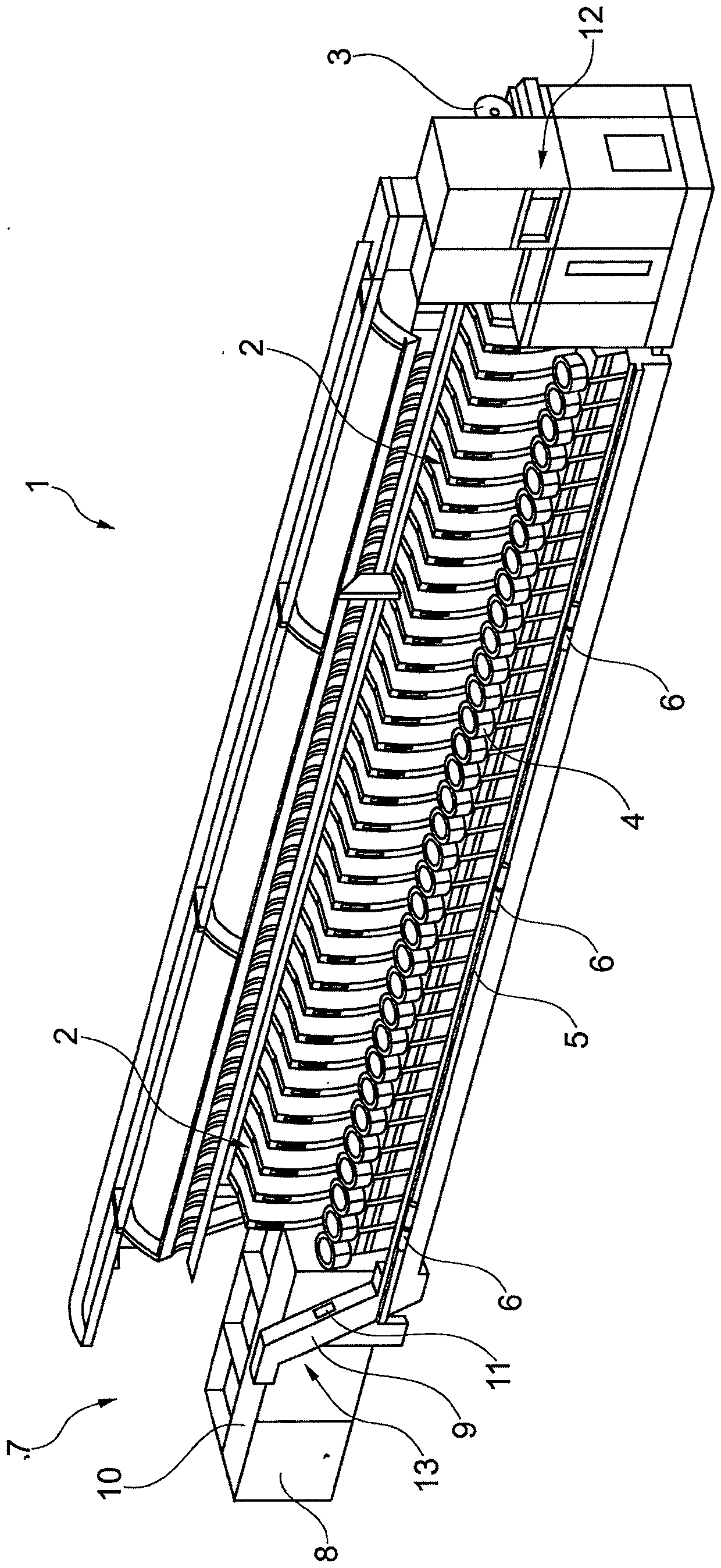

[0039] figure 1 Several of the side-by-side winding stations 2 of the automatic winding machine 1 are shown in perspective.

[0040] On such a winding station 2, the bobbin is fed and is preferably a cross-wound bobbin 3 which is rewound into a large package from a spinning bobbin produced on a ring spinning machine with less yarn material, Therefore, the yarn is also monitored for yarn defects during rewinding, which are removed as required.

[0041] The cross-winding bobbin 3 is rotated by the guide drum during the winding process, and the yarn-guiding drum is also used to orderly traverse the yarn unwound from the feeding bobbin during its winding onto the cross-winding bobbin 3. move.

[0042] Yarn handling and monitoring devices which are required in connection with such rewinding of feed bobbins and removal of yarn defects, which are respectively arranged in the region of the yarn movement path on the winding station, are known. Since said yarn processing and monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com