Continuous rolling device for spinning and dyeing

A winding device, textile printing and dyeing technology, applied in textile and papermaking, textile processing machine accessories, textile material processing and other directions, can solve problems such as reducing production efficiency and difficult to meet efficient production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

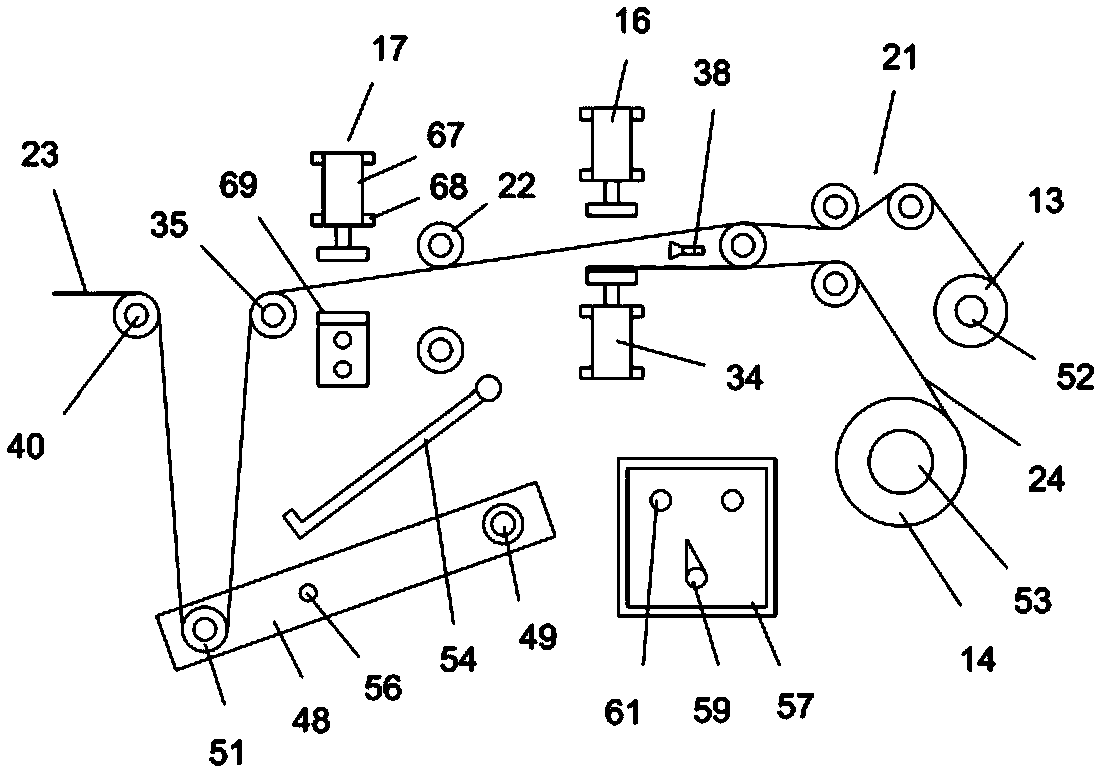

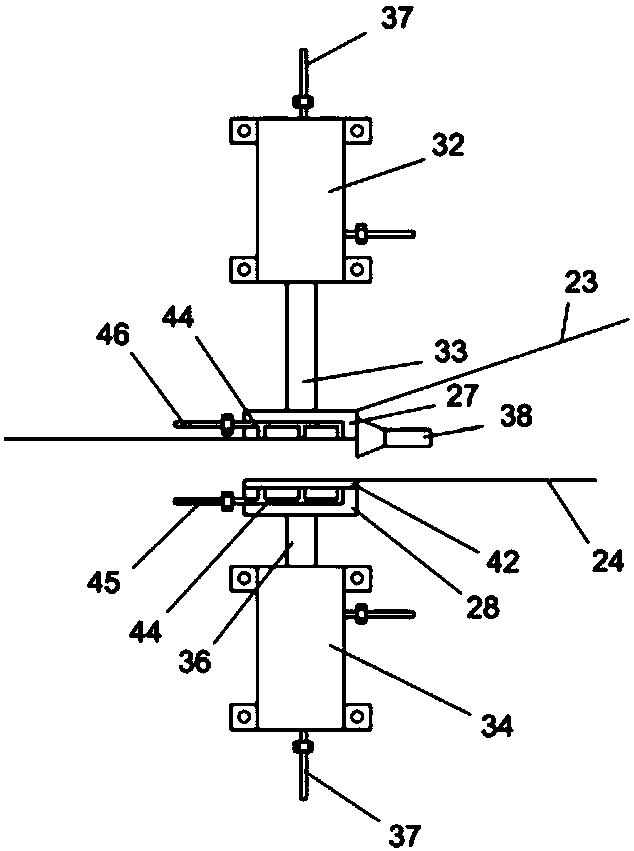

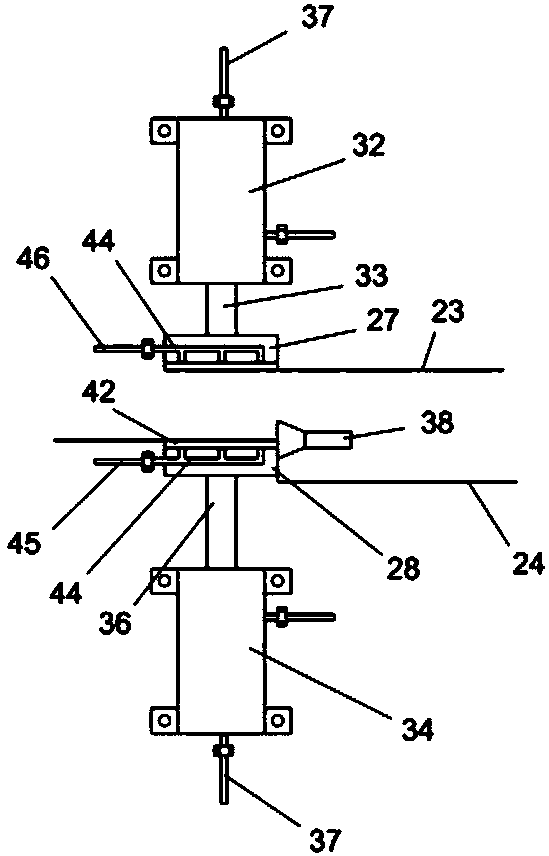

[0019] like Figure 1-3 Shown, a kind of textile printing and dyeing continuous winding device, it comprises feed roller one 13 and feed roller two 14, and feed roller one 13 and feed roller two 14 are sequentially fed; Cloth braking table 17, the first cloth 23 from feed roller one 13 and the second cloth 24 from feed roller two 14 pass through splicing table 16, the first cloth 23 and the second cloth 24 pass through splicing table 16 upstream The set of rollers 21 is arranged and maintained in a parallel spaced relationship, the first fabric 23 extends to the fabric braking platform 17 through the splicing platform 16, and the second fabric 24 terminates at the front end of the splicing platform 16; the splicing platform 16 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com