Excavation support structure and construction method for an auxiliary cavern of a sandy gravel layer tunnel

A technology for supporting structures and stone layers, applied in water conservancy projects, buildings, hydroelectric power stations, etc., can solve the problems of easy loosening of the surrounding rock of the sand and gravel layer, high construction safety risks, and difficulty in initial support, so as to reduce the excavation rate. The effect of supporting difficulty, flexible and fast installation, and reducing the amount of excavation works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

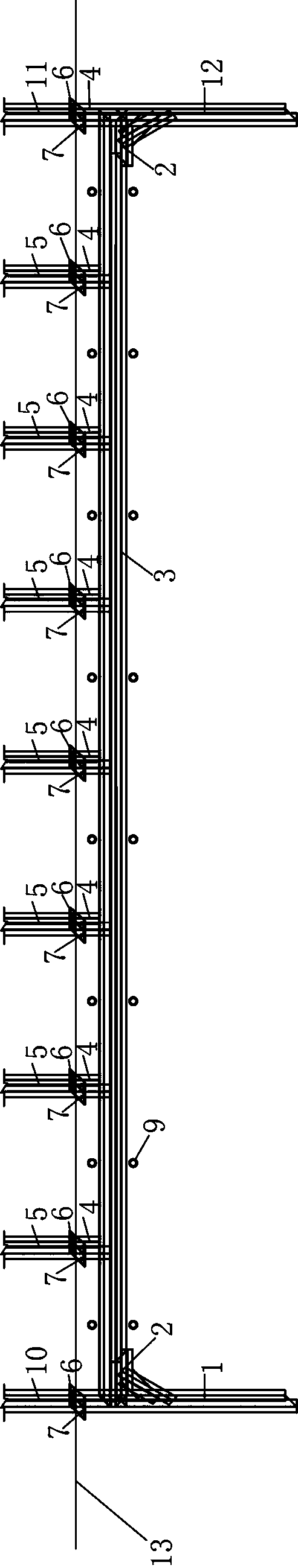

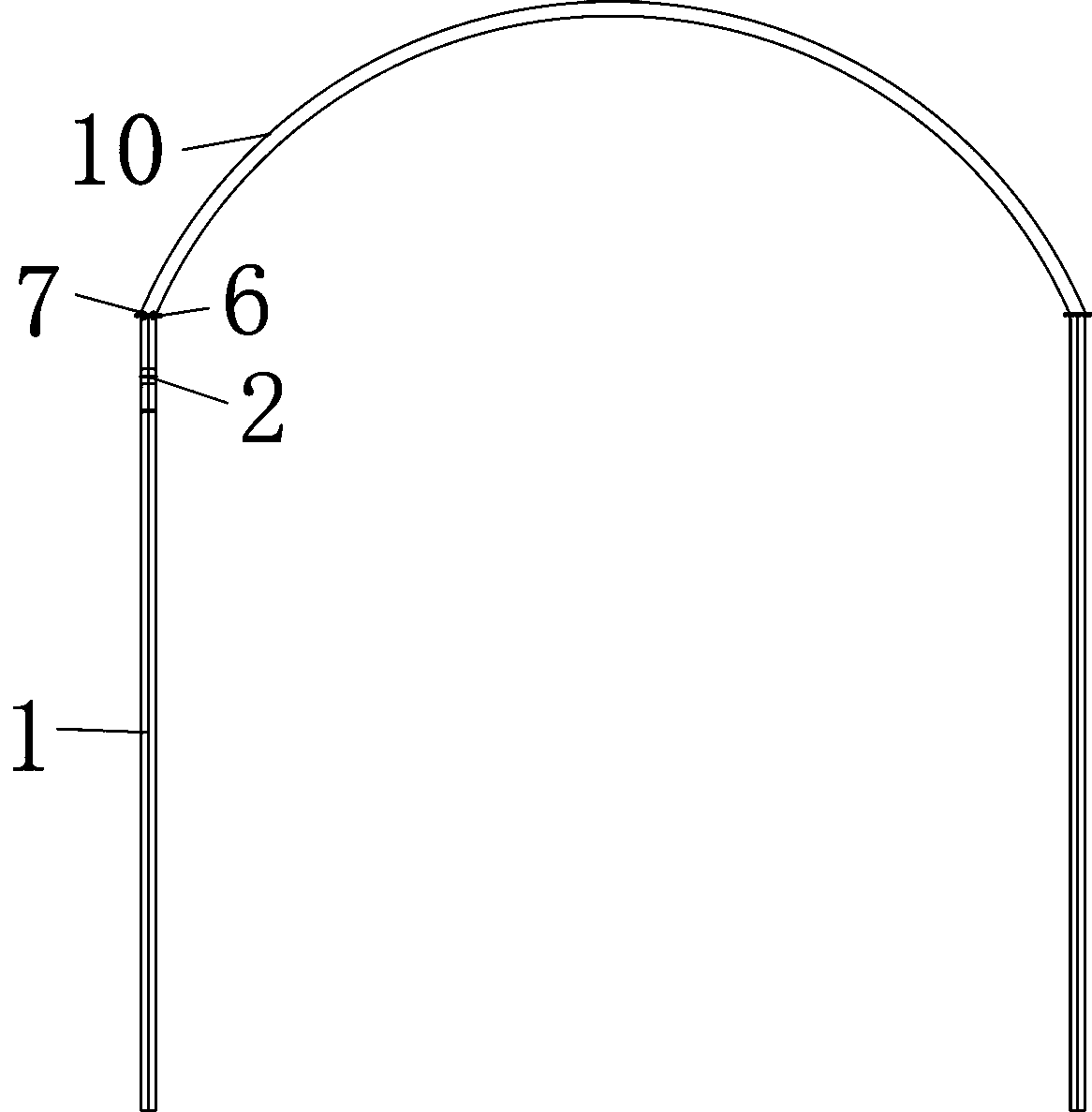

[0034] like figure 1 and figure 2 As shown, a supporting structure for the excavation of an auxiliary cavern of a sandy gravel layer tunnel, including a first column 1 and a second column 12 erected on the side walls on both sides of the door of the auxiliary cavern, the first column 1 and the second column 12 Corbels 2 with card slots are arranged on the top, and the two ends of the beam 3 are welded and fixed in the card slots of the corbel 2. The beam 3 passes through multiple supporting piers 4 and multiple arc-shaped I-shaped top arches on the top of the attached cavern. Steel 5 is fixedly connected, and the first column 1 and the second column 12 are respectively fixedly connected with one end of the top arch arc-shaped I-steel 10 of the first column and the arc-shaped I-steel 11 of the second column top arch, forming a rectangular entrance of an attached cavern supporting structure.

[0035] Between the first column 1 and the arc-shaped I-steel 10 at the top of the f...

Embodiment 2

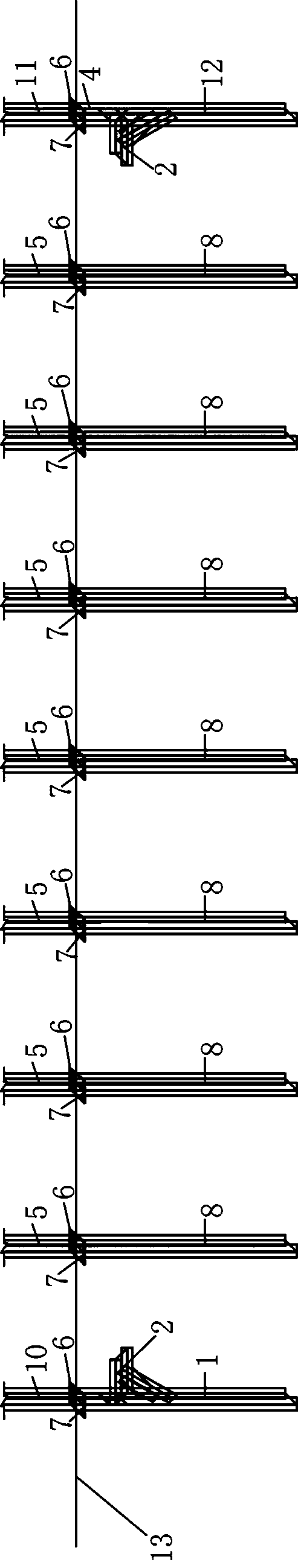

[0041] like image 3 , Figure 4 and Figure 5 As shown, a construction method for excavating an auxiliary cavern of a sand and gravel layer tunnel using the above-mentioned support structure, the method includes the following steps:

[0042] Step 1: Use a high-power excavator to excavate the sand and gravel layer tunnel along the arch line 13, and use steel arches for initial support;

[0043]Step 2: When excavating to the stake number 1 meter from the starting point of the door of the auxiliary cavern, erect the first column 1 on the side wall of the auxiliary cavern, and weld the corbel with a slot on the upper end of the first column 1 2. Use the arc-shaped I-steel 10 of the top arch of the first column for initial support, and the arc-shaped I-steel 10 of the top arch of the first column and the first column 1 are connected by bolts 7 through the connecting plate 6;

[0044] Step 3: Along with the excavation of the gravel layer tunnel, set up a plurality of subsequent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com