Threaded column cement piling machine

A technology for cement piles and threaded columns is applied in the field of construction equipment, which can solve the problems of waste, reduce the bearing capacity of ground piles, and use more raw materials, and achieve the effects of improving the utilization rate, increasing the bearing capacity of the pile body, and reducing the working strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

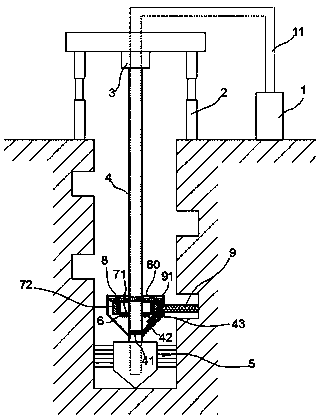

[0022] exist figure 1 , figure 2 In the shown embodiment, this threaded column cement pile driver includes a grouting machine 1, a guide pipe 11, a lifting frame 2, a driving machine 3, and also includes a driving rod 4 installed on the driving machine 3. The end of 4 is equipped with drill bit 5;

[0023] One end of the guide pipe 11 is connected to the grouting machine 1, and the other end extends along the driving rod 4 and communicates with the grouting port on the drill bit 5;

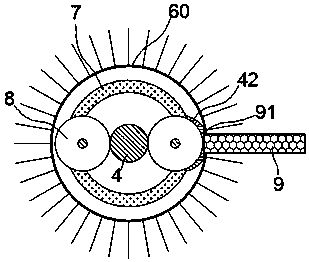

[0024] A threaded drill is provided on the drive rod 4, and the threaded drill includes a dustproof casing 60, and a limit ring 6 is arranged in the dustproof casing 60, and the limit ring 6 is fixedly installed on the On the drive rod 4; an adjustment ring 7 is installed close to the limit ring 6, and the adjustment ring 7 includes a chassis 71 and a ring body 72, and the chassis 71 is sleeved on the drive rod 4; The surface of the chassis 71 and the limit ring 6 are provided with matching ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com