Acrylic plate daylighting workshop

An acrylic board and acrylic technology, applied in industrial buildings, building components, buildings, etc., can solve the problems of insufficient glass strength, limited lighting, accidents, etc., and achieve the effects of avoiding lighting dead ends, high surface gloss, and good high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

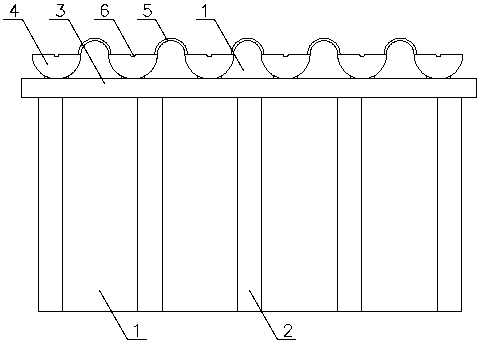

[0012] As shown in the figure, an acrylic board daylighting factory building includes a wall 1, a row of vertical beams 2 are respectively arranged in the front and rear walls of the wall, and the top of each row of vertical beams 2 is supported by a crossbeam 3, and the two crossbeams 3 There are multiple longitudinal beams 4 arranged at equal intervals between the supports, and acrylic light-transmitting panels 5 are installed between adjacent longitudinal beams 4. The longitudinal beams 4 are semi-cylindrical, and the top surface of the longitudinal beams 4 is a plane. A drainage groove 6 is provided; the arc surface of the longitudinal beam 4 faces downward; the acrylic light-transmitting plate 5 is an arc-shaped curved surface, the arc-shaped surface faces upward, and the two ends of the arc-shaped surface are tangent to the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com