A method for head-on prevention of top-coal leakage in coal roadway tunneling in extremely soft and thick coal seams in sliding structural areas

A technology with thick coal seam and softness, which is applied in the field of head-to-head coal leakage prevention in the excavation of extremely soft and thick coal seams in the sliding structure area, and can solve the problem of the imperfection of the bolt mesh support theory in the coal roadway of extremely soft and thick coal seams, and the weakening of the head-head coal in the excavation. It can solve the problems such as the difficulty of anchoring and net support in the coal roadway, so as to solve the problem of easy leakage of coal at the head of the roadway, ensure smooth implementation, and be easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Glossary:

[0024] Circular step distance: the circular excavation step distance, which refers to the advancing distance of the roadway between the two previous and subsequent excavation constructions in the advancing direction of the roadway excavation working face.

[0025] Anchor row spacing: refers to the distance between every two rows of anchor rods.

[0026] Anchor spacing: refers to the distance between the same row of anchors.

[0027] Row spacing between anchors: refers to the distance between every two rows of anchors and the distance between the same row of anchors.

[0028] This example takes the recovery roadway of a mine in Zhengzhou Coal Industry Group as an example. The thickness of the coal seam is 7.2m, the height of the roadway is 3.5m, and the width is 5.0m.

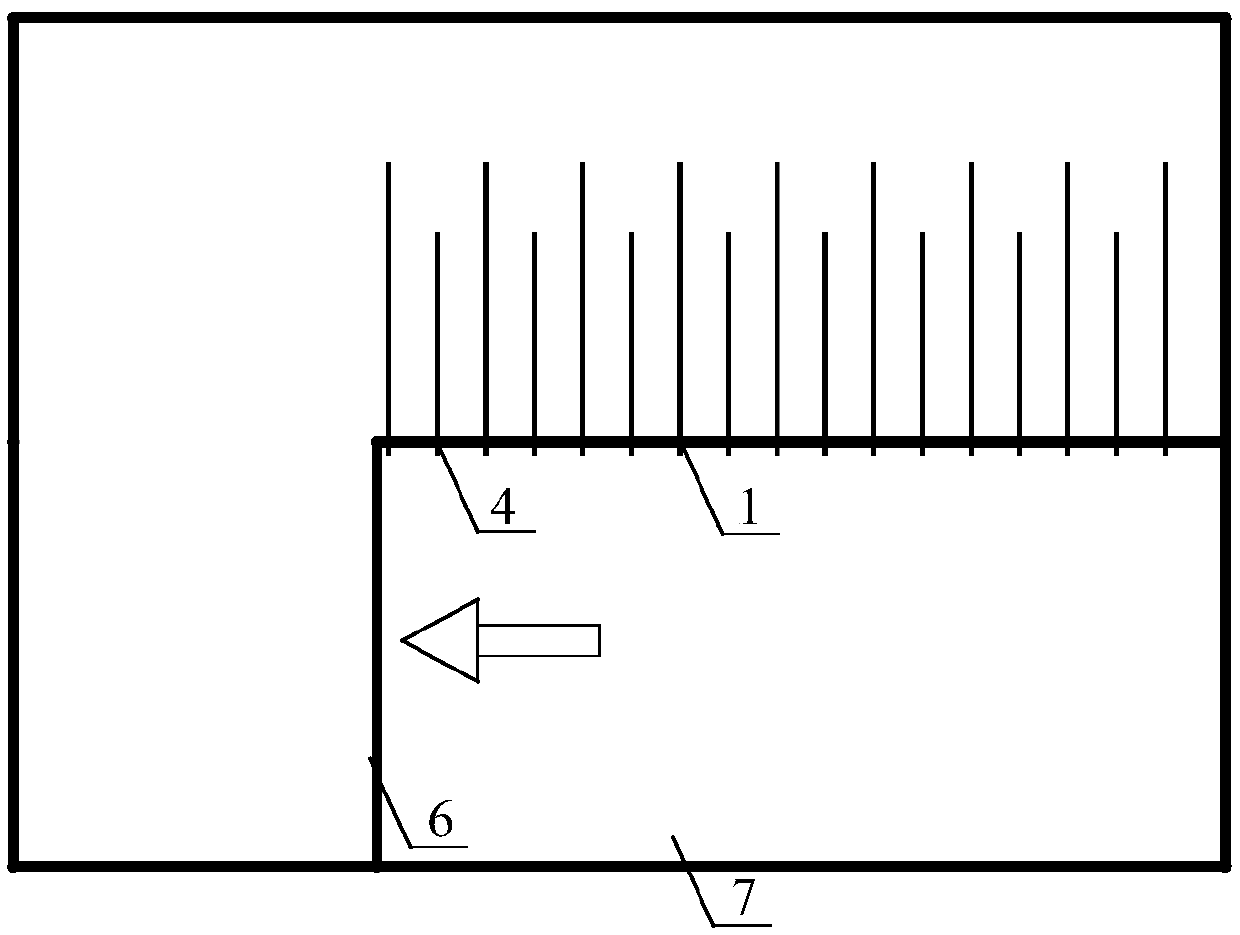

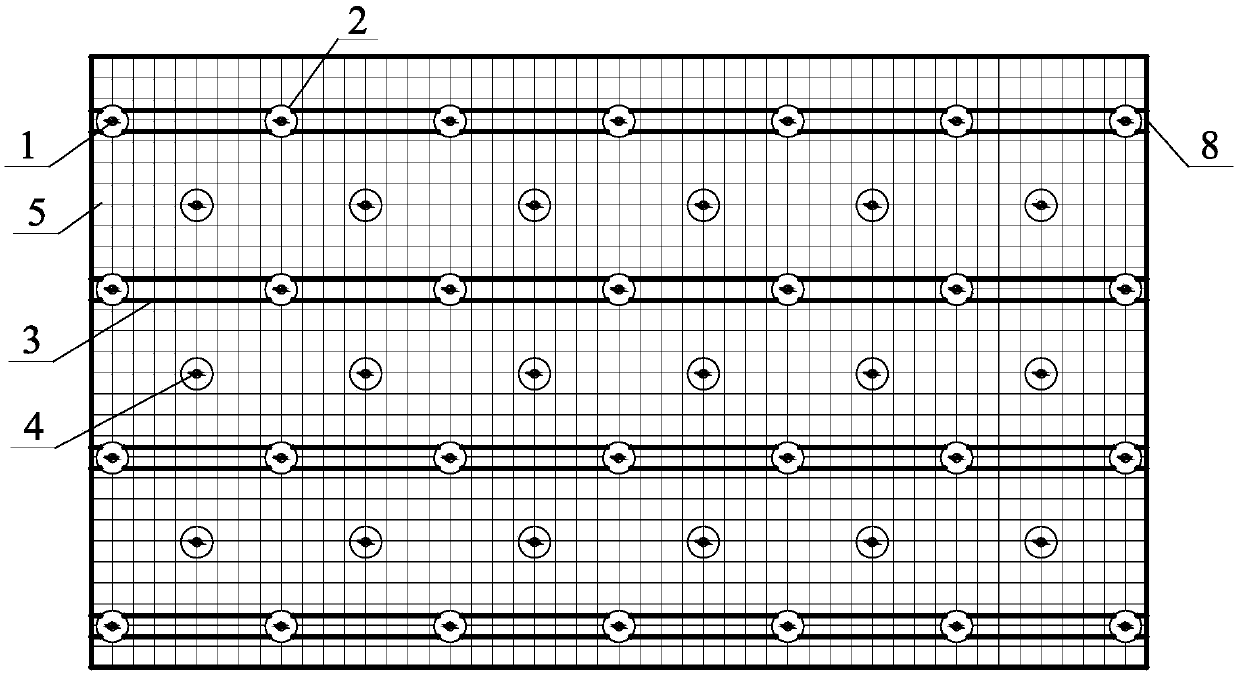

[0029] Such as figure 1 , figure 2 Shown, a kind of sliding structure area e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com