High-performance solid ablation type pulse plasma electric propulsion device

A technology of pulsed plasma and solid propellant, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of unstable thrust performance, weakened electromagnetic acceleration performance, long discharge time, etc., to improve the thrust effect. And work efficiency, improve the effect of electrothermal acceleration, the effect of large discharge ablation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The essence of the low performance of the solid ablative pulsed plasma electric propulsion device lies in the low utilization rate of the propellant. In order to solve the above technical problems, the present invention proposes a new type of electric propulsion device, which can effectively improve the electrothermal and electromagnetic acceleration impulse, thrust, total impulse and overall thrust efficiency of the plasma formed by propellant ablation, and finally improve Performance of electric propulsion units.

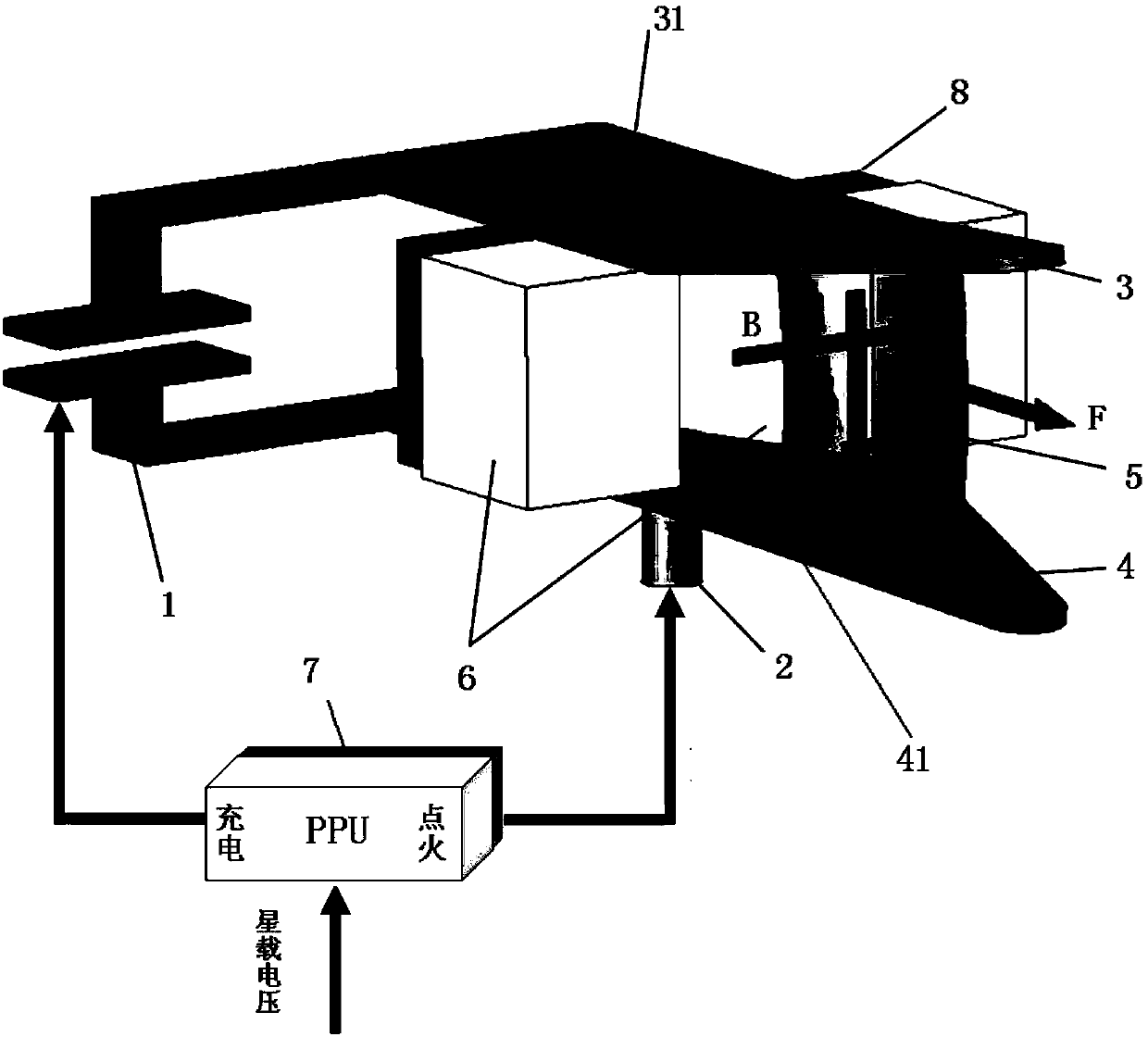

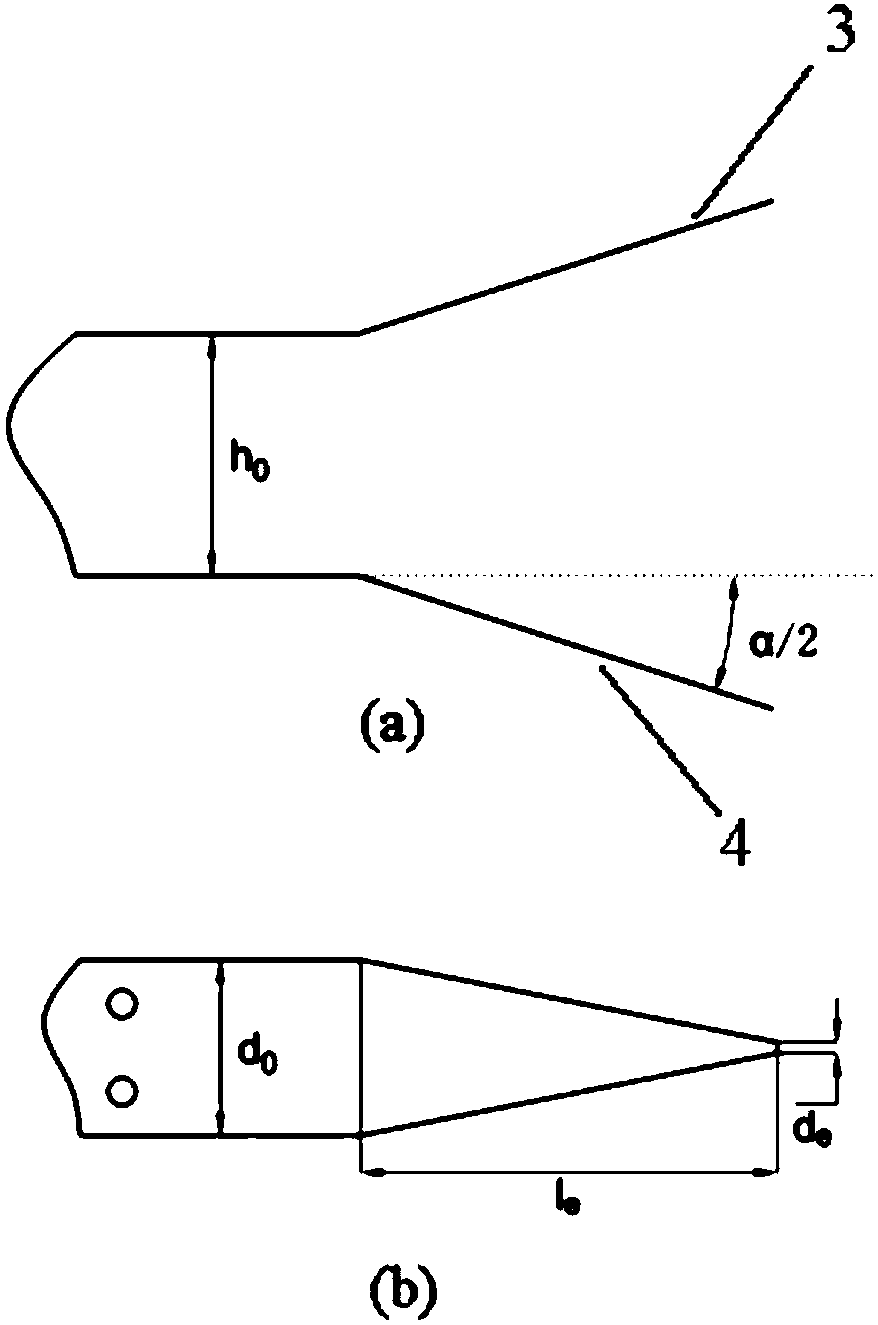

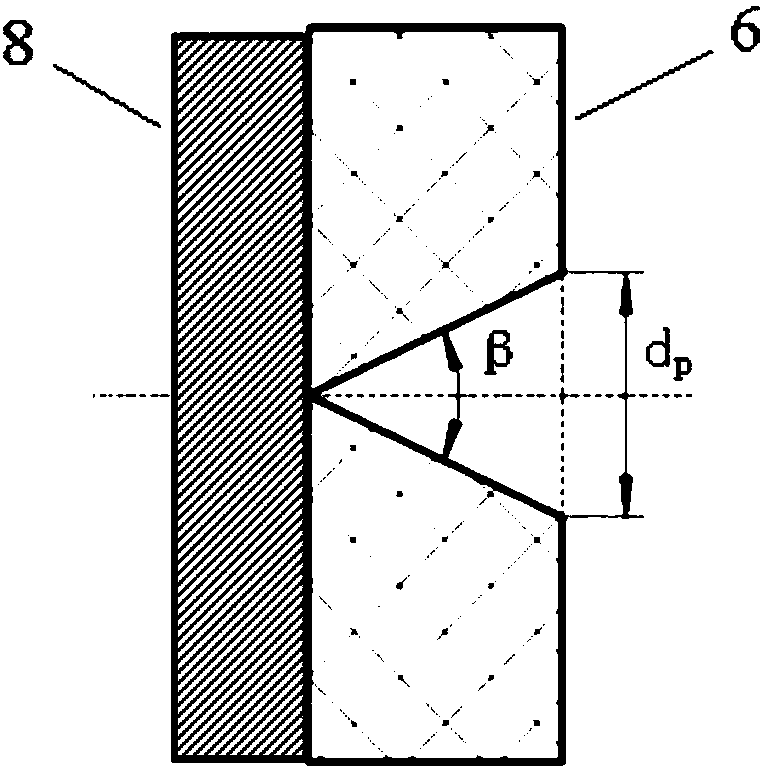

[0026] like figure 1 As shown, the device of the present invention includes an energy storage capacitor 1 , a spark plug 2 , an anode 3 , a cathode 4 , a propellant block 6 , a power processing unit PPU 7 , an insulating material 8 , an anode conductive plate 31 and a cathode conductive plate 41 . The anode 3 is connected to the anode of the energy storage capacitor 1 through the anode conductive plate 31, the cathode 4 is connected to the cathode of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com