Permanent magnet transmission torque converter double-input-shaft drive device

A permanent magnet transmission, dual input shaft technology, applied in transmission, gear transmission, transmission parts, etc., can solve the problems of friction plate temperature rise, body vibration, teeth rattle and other problems, to achieve torque adjustment can be achieved. Guaranteed controllability, avoiding slippage and damage, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

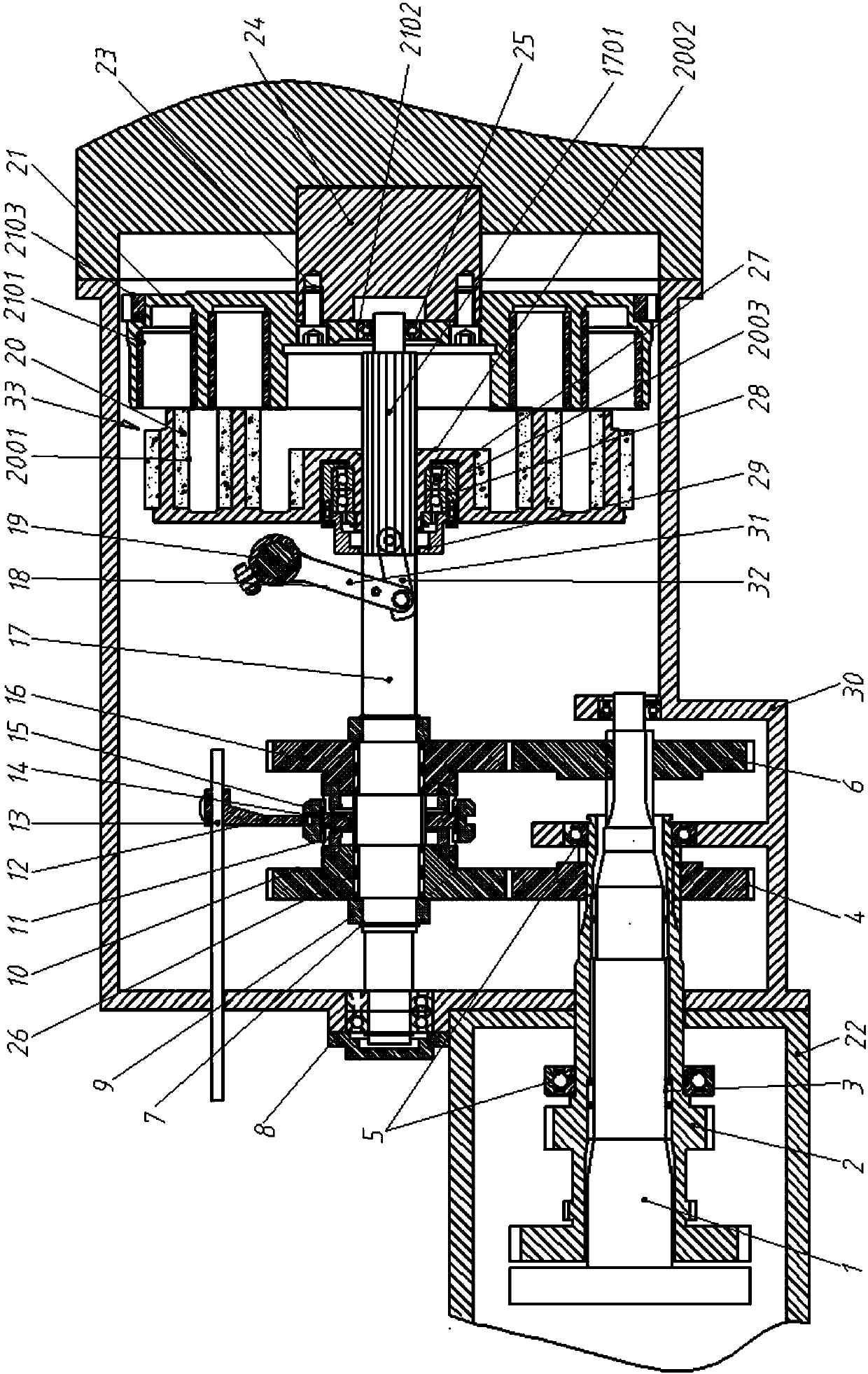

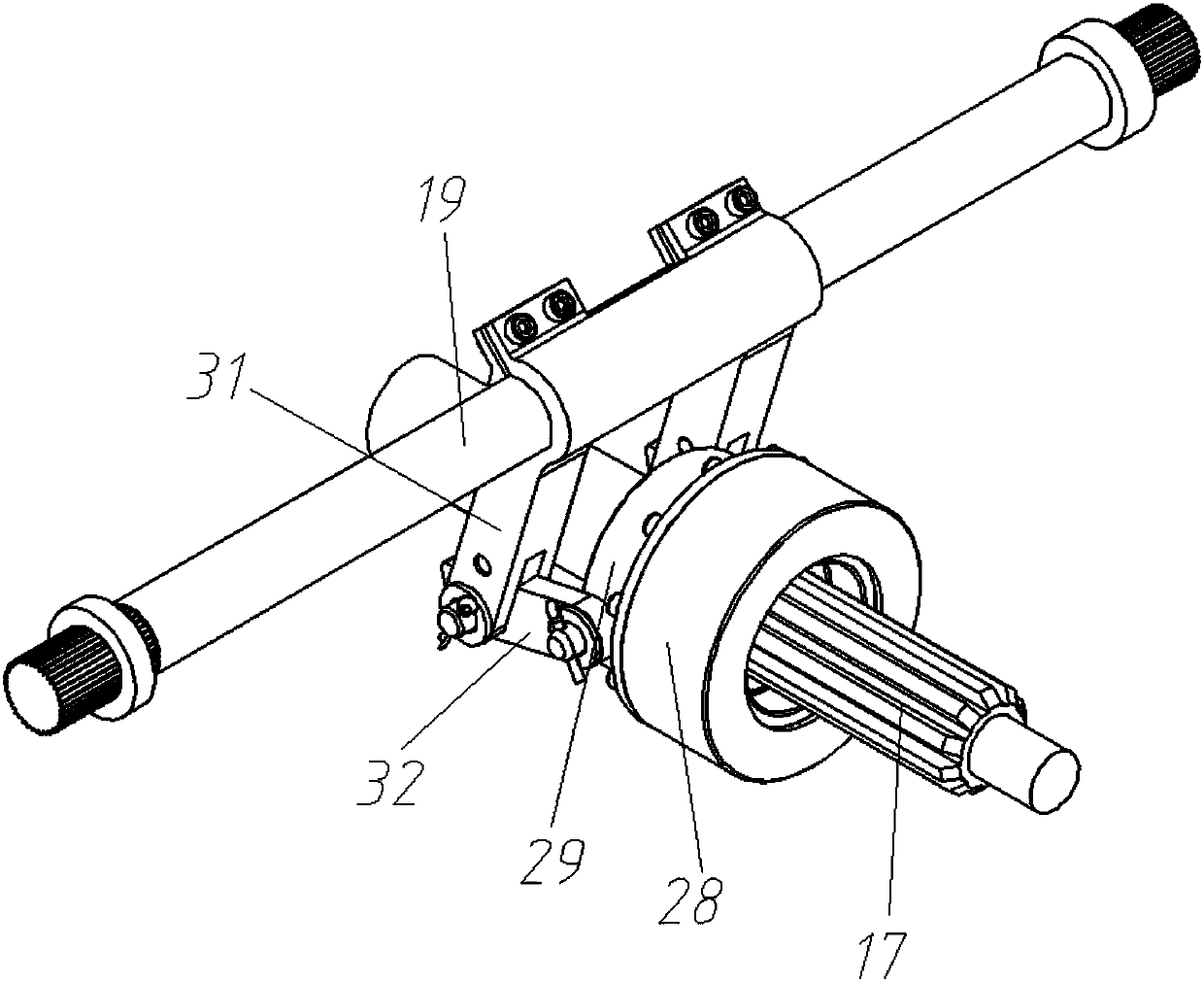

[0017] Attached below Figure 1-2 Embodiments of the present invention are described.

[0018] Permanent magnet transmission torque converter dual input shaft drives such as figure 1 As shown, it includes a housing 30 and an input shaft I1 and an input shaft II2 connected to the input end of the gearbox. The input shaft II2 is a hollow structure, and one side of the housing 30 is connected to a connecting housing 22. The input shaft II2 is supported in the casing 30 and the connection casing 22 through the bearing VI5, the input shaft I1 is rotatably supported in the inner cavity of the input shaft II2 through the bearing V3 and one end extends out of the input shaft II2, and is also rotatably supported in the casing 30 and the transmission shaft 17 between the crankshaft 24 of the engine.

[0019] One end of the transmission shaft 17 close to the engine crankshaft 24 is provided with a permanent magnet transmission torque conversion device 33, specifically, the permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com