Pipe gallery construction formwork jumbo control system

A formwork trolley and control system technology, applied in the field of hydraulic control, can solve problems such as affecting construction efficiency, affecting formwork efficiency, low transmission efficiency, etc., to achieve improved efficiency and accuracy, guarantee formwork efficiency, and a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

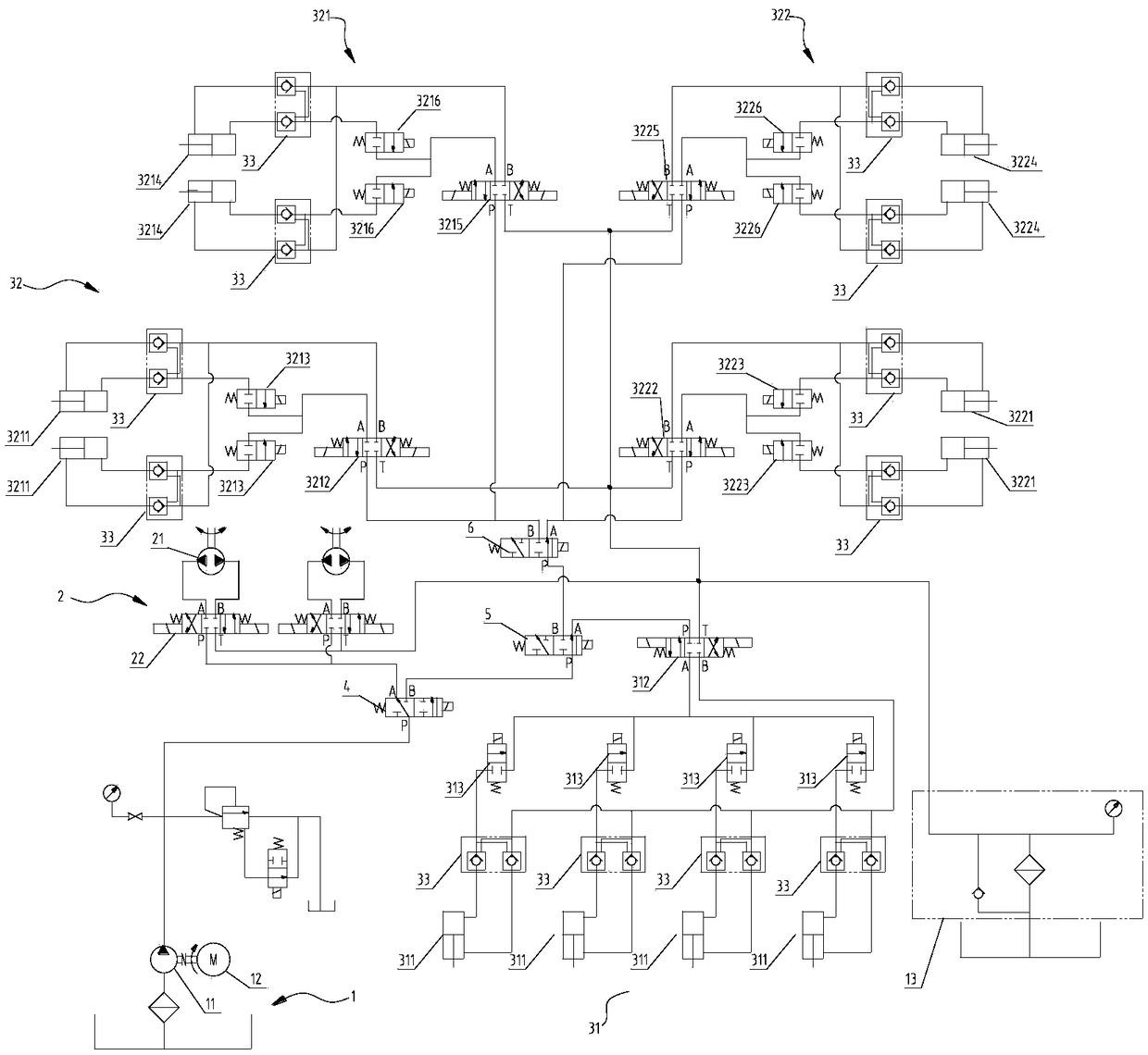

[0027] Such as figure 1 As shown, the control system of the formwork trolley for pipe gallery construction includes oil supply system 1, travel system 2, formwork support system 3 and two-position three-way valve A4;

[0028] The oil supply system 1 includes an oil pump 11 and an electric motor 12 arranged on the main oil inlet pipeline, and the electric motor 12 drives the oil pump 11 to provide hydraulic oil required by the entire control system;

[0029] The walking system 2 includes a hydraulic motor 21 and a motor reversing valve 22; the working port of the motor reversing valve 22 communicates with the corresponding oil port of the hydraulic motor 21;

[0030] One of the oil outlets of the two-position three-way valve A4 is connected to the oil inlet of the motor reversing valve 22 through the corresponding oil inlet pipeline, and the other oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com