Battery case strength detection equipment used for lithium battery production

A strength detection and battery shell technology, applied in the direction of secondary batteries, electrochemical generators, battery pack components, etc., can solve the problems of battery leakage, poor fixing stability, high labor intensity, etc., to reduce work intensity, fix Good stability and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

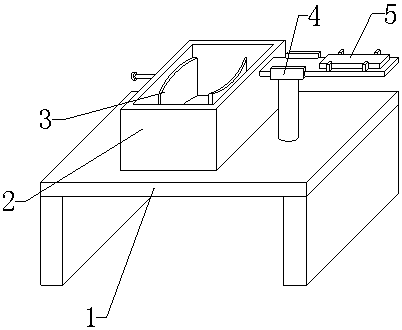

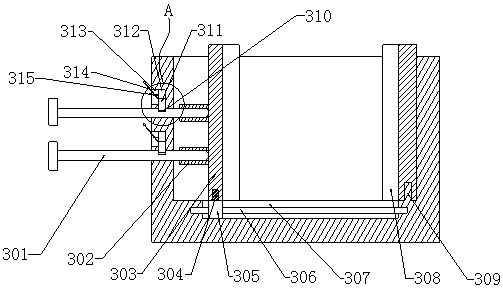

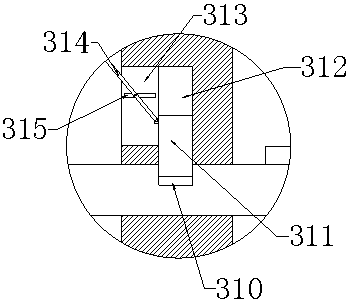

[0022] see Figure 1-Figure 4 , the present invention provides a technical solution: a battery shell strength testing device for lithium battery production, including an operating table 1, a box body 2, a clamping assembly 3, a detection and adjustment assembly 4, and a weld detector 5, and the box body 2 is fixed On the upper end surface of the console 1, the clamping assembly 3 is installed inside the box body 2, and the clamping assembly 3 includes a support rod 301, a connecting cylinder 302, a moving splint 303, a clamping boss 1 304, a ball nut seat 305, and a screw rod 306 , moving slot 307, fixed splint 308, clamping boss 2 309, clamping groove 310, clamping block 311, chute 1 312, through hole 313, pull rod 314 and chute 2 315, the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com