Lead-free paste used for novel solar battery electrode assembly

A technology for solar cells and electrode components, applied in the direction of conductive materials, conductive materials, electrical components, etc., can solve the problems of affecting the service life of solar cell modules, large differences in linear expansion coefficients, cracking and damage of silicon plates, etc., to avoid silicon wafers Cracking phenomenon, improved electrical and thermal conductivity, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

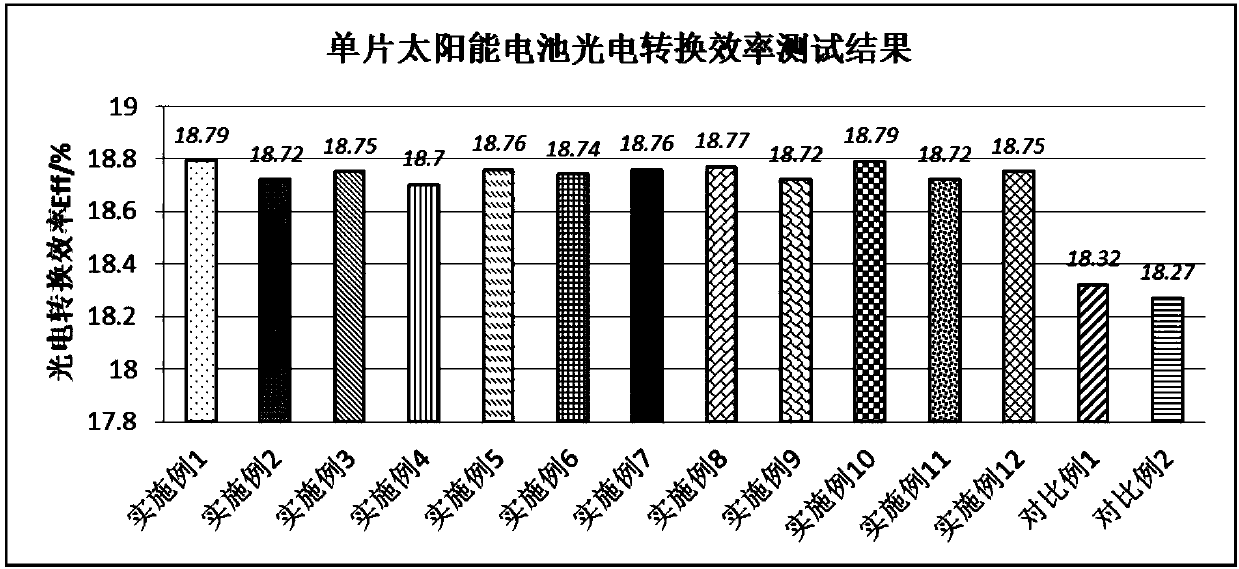

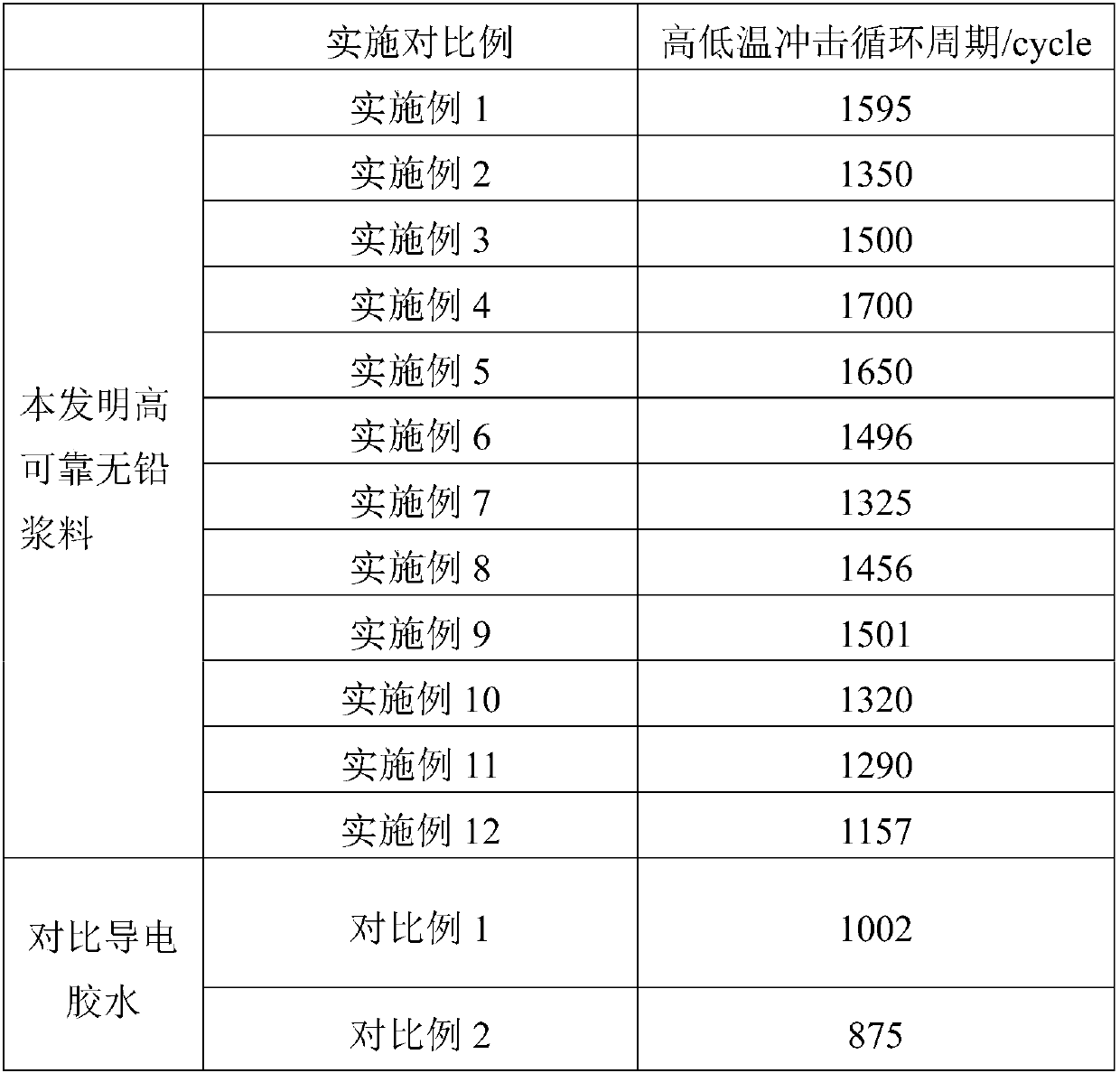

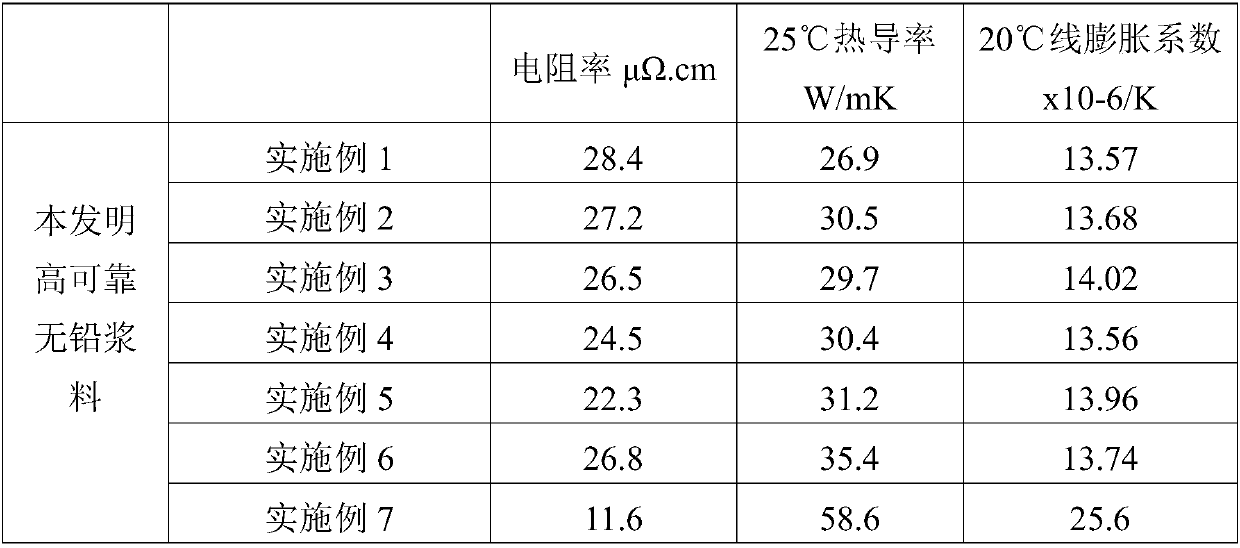

Examples

Example Embodiment

[0026] Example 1

[0027] A new type of lead-free paste for solar cell electrode components. The prepared Sn-Bi-Sb-Ni alloy powder is added with flux and stirred into a lead-free solder paste. T3 (25-45μm) type powder is selected, and the flux ratio is 11.5%. The prepared solder paste is screen-printed to the through-hole electrode lattice, heated and cured at a curing temperature of 170°C, and the curing time is 4 minutes to form a through-hole electrode, which forms an ohmic connection with the battery silicon plate, and is used to derive the nearby light output Current. The lead-free solder paste alloy powder contains: Bi 45%, Sb 2.5%, Ni 0.005%, and the rest is Sn.

Example Embodiment

[0028] Example 2

[0029] A new type of lead-free paste for solar cell electrode components. The prepared Sn-Bi-Sb-Ni-Ag-Cr alloy powder is stirred into a lead-free solder paste with flux, and T5 (15-25μm) type powder is selected. The flux ratio is 15%. Apply the prepared solder paste to the through-hole electrode dot matrix through a syringe, heat and cure at a curing temperature of 168°C, and a curing time of 4.5min to form a through-hole electrode, which forms an ohmic connection with the battery silicon plate for exporting nearby Light out current. The lead-free solder paste alloy powder contains: Bi 60%, Sb 7.0%, Ni 0.1%, Ag 2.1%, and the rest is Sn.

Example Embodiment

[0030] Example 3

[0031] A new type of lead-free paste for solar cell electrode components. The prepared Sn-Bi-Al-Ag-Cu alloy powder is added with flux and stirred into a lead-free solder paste. T3 (25-45μm) type powder and flux are selected The ratio is 8%. The prepared solder paste is screen-printed to the through-hole electrode lattice, heated and cured at a curing temperature of 175°C, and the curing time is 3.8 minutes to form a through-hole electrode, which forms an ohmic connection with the silicon plate of the battery, and is used to extract the light nearby. Out of current. The lead-free solder paste alloy powder contains: Bi50%, Al 1.8%, Cu 0.5%, Ag 1.5%, and the rest is Sn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com