Low-cost high-reliability position detecting device of permanent-magnet synchronous motor

A permanent magnet synchronous motor and detection device technology, applied in the direction of electronic commutator, etc., can solve the problems of increasing the difficulty of fault judgment, increasing sensor faults, etc., and achieve the effects of improving work reliability, reducing failure probability and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

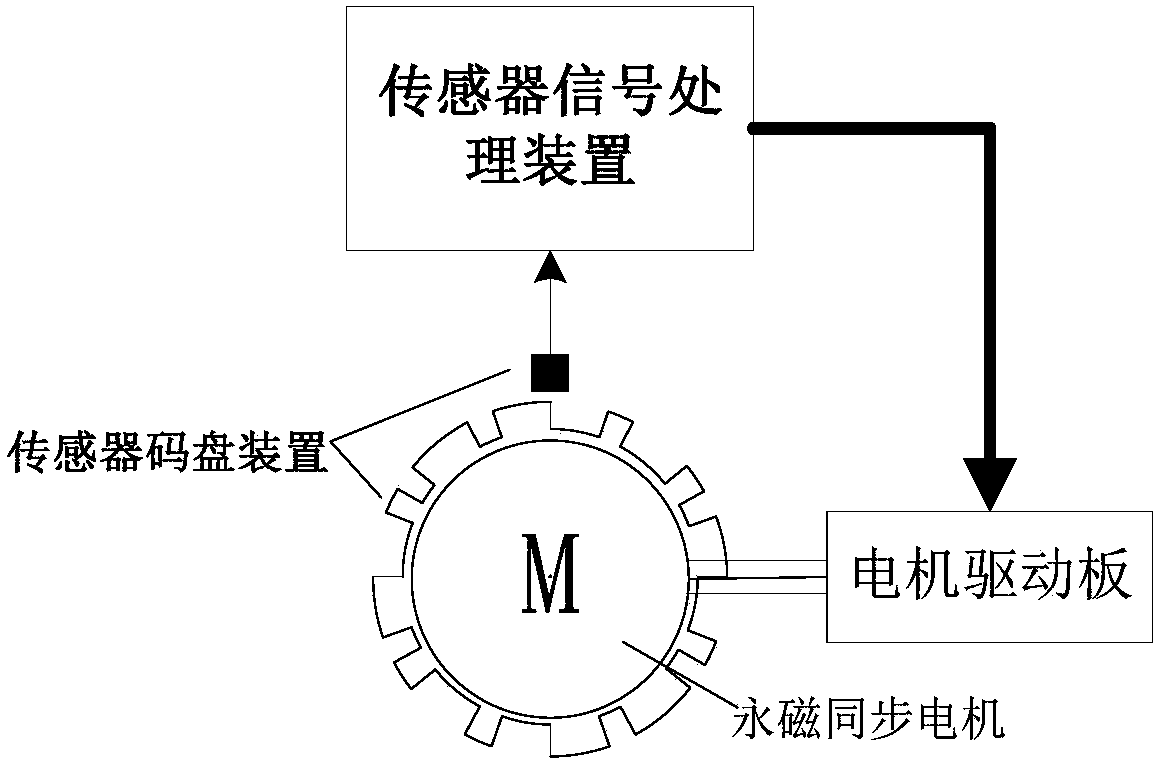

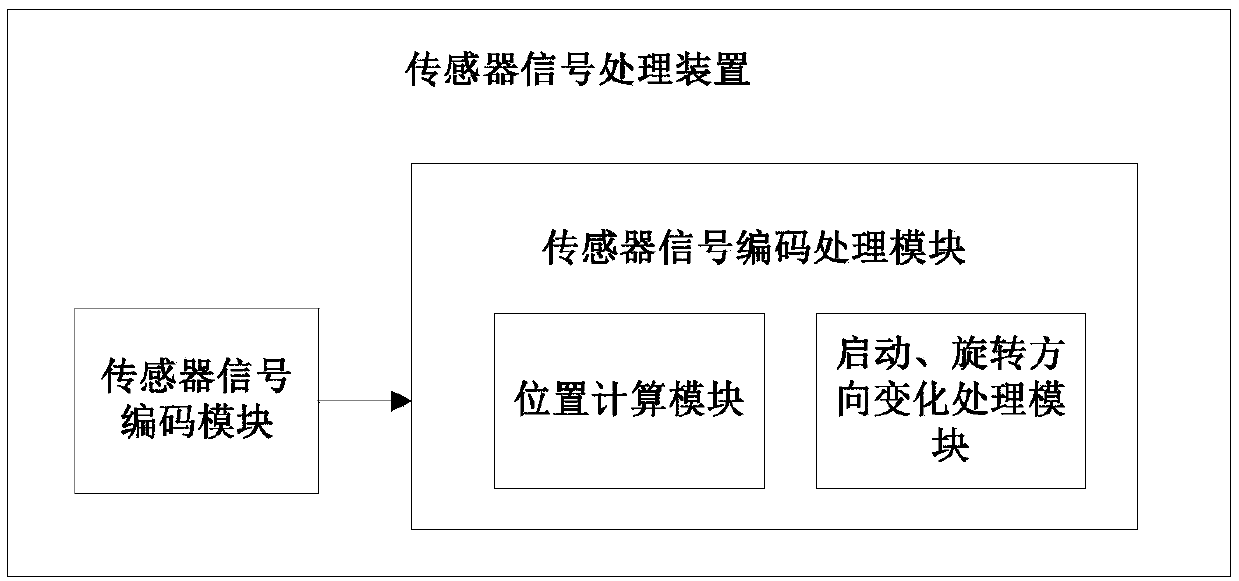

[0036] Such as figure 1 As shown, a low-cost and high-reliability permanent magnet synchronous motor position detection device in this embodiment includes a detection part that rotates synchronously with the motor, and is coupled with the detection part and outputs high and low levels according to the position state of the detection part. A single sensor, and a sensor signal processing device that receives the detection signal of the sensor and calculates the position information of the motor rotor.

[0037] In this embodiment, the detection part uses a suitable code disc to detect the position information of the rotor of the motor through a single sensor.

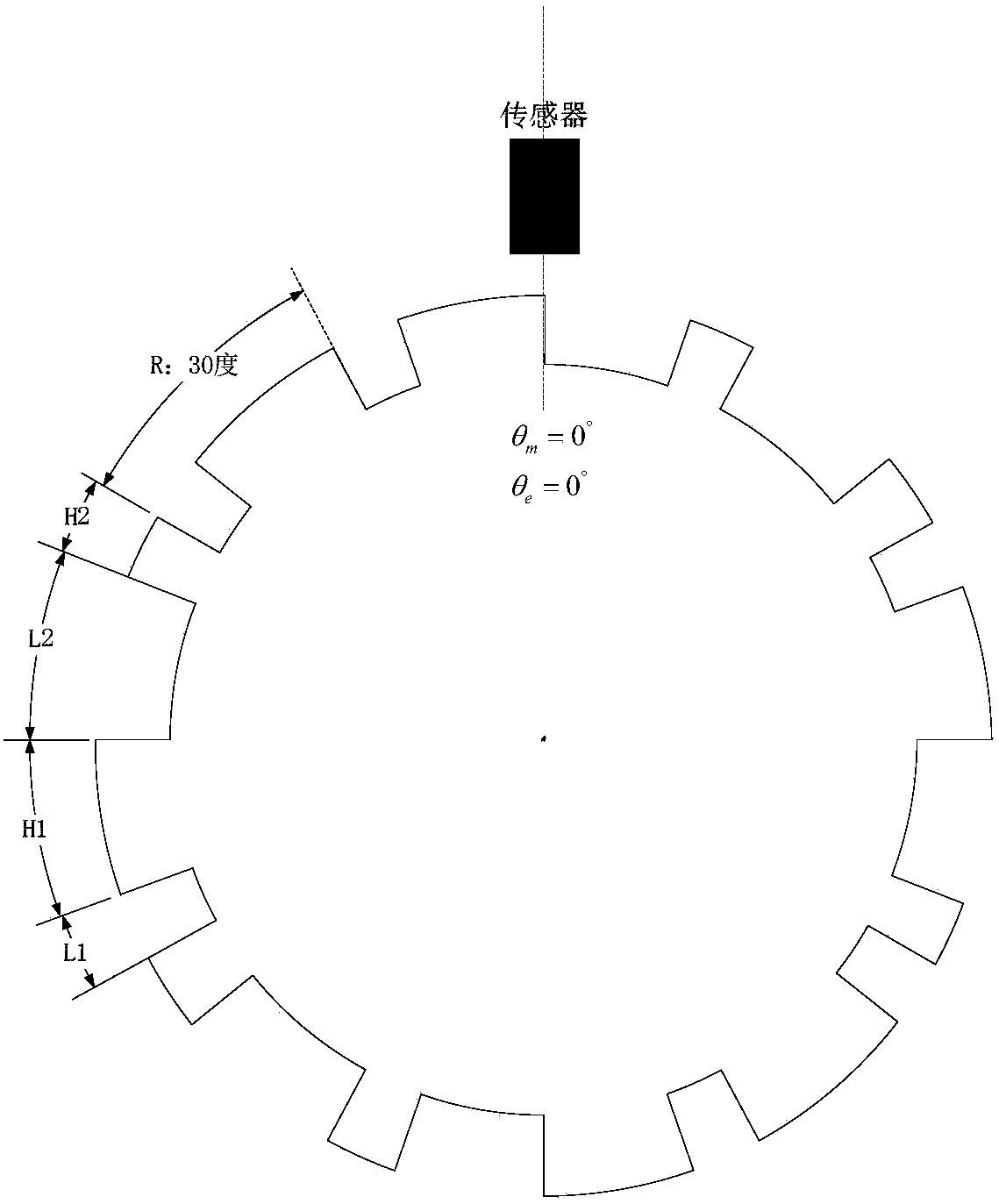

[0038] Such as image 3 A single sensor is shown and detects the corresponding code wheel. The code disc is a code disc matching a three-phase permanent magnet synchronous motor with 12 slots and 4 poles, and the code disc is coaxially fixed with the rotor of the motor. The convex part of the code wheel is indicated by ...

Embodiment 2

[0074] A low-cost and high-reliability permanent magnet synchronous motor position detection device in this embodiment includes a single sensor device and a sensor signal processing device. Compared with the first embodiment, this embodiment does not use a code disc, and the detection part uses the magnetic poles of the motor rotor. The sensor outputs a corresponding high-level or low-level detection signal according to the N magnetic pole or the S magnetic pole of the motor rotor. When the motor rotates, the sensor device outputs a series of square wave signals with the same width and width, which are input to the sensor signal processing device, and the position information is obtained after processing.

[0075] Such as Figure 12 As shown, the number of sensors in this embodiment is one, which is installed in a three-phase permanent magnet synchronous motor with 12 slots and 4 poles to detect the polarity change of the 4-pole rotor.

[0076] The sensor in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com