Machine tool inspection window with smog fire extinguishing function

An observation window and machine tool technology, which is applied in fire rescue, manufacturing tools, metal processing machinery parts, etc., can solve the problems of long time for water spray pulverization, high processing cost, poor pulverization effect, etc., and maintain visual clarity. , high safety, good fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

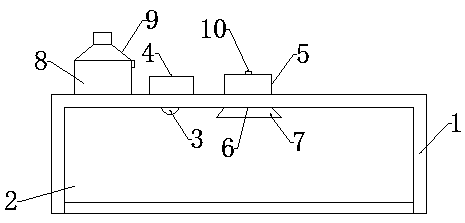

[0021] Such as figure 1 As shown, a machine tool observation window with smoke and fire extinguishing function includes a groove-shaped aluminum alloy bracket 1 for covering the machine tool, and a transparent observation plate 2 is embedded on the side and top of the aluminum alloy bracket 1, and the observation plate 2 is provided with a smoke sensor 3 located in the groove of the aluminum alloy bracket 1, the smoke sensor 3 is connected to a controller 4, and a foam fire extinguisher 5 is provided above the top observation board 2, and the switch of the foam fire extinguisher 5 is controlled by the controller 4. The ejection port 6 of the foam fire extinguisher 5 communicates with the top observation board 2 . Through the transparent observation board 2, the process of parts processing on the machine tool can be clearly observed and supervised, and it can prevent the possible occurrence of electric sparks splashing and parts falling off during the processing, which may caus...

Embodiment 2

[0023] This embodiment is further defined on the basis of the above-mentioned embodiments, the connection between the foam fire extinguisher 5 and the observation panel 2 is provided with a spray cover 7 with the opening facing downward. The spray cover 7 can make carbon dioxide better enter the groove of the aluminum alloy bracket 1 .

[0024] Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0026] This embodiment is further defined on the basis of the above-mentioned embodiments. The top of the observation board 2 is provided with a smoke extraction device. The smoke extraction device includes a gas collection hood 8 communicated with the observation The air suction pump 9 at the top, the switch of the air suction pump 9 is connected with the controller 4. When the smoke sensor 3 senses that the smoke concentration reaches a certain value, the controller 4 turns on the switch of the air pump 9, and the smoke in the aluminum alloy bracket 1 will be discharged from the air pump 9 through the gas collecting hood 8, so that the groove of the aluminum alloy bracket 1 Keep the visibility of the air inside.

[0027] Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap