Ultrasonic cleaning device capable of drying workpiece

A cleaning device and ultrasonic technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of inability to carry out thorough cleaning, increase labor, reduce work efficiency, etc., to improve cleaning effect and reduce product waste. rate, good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

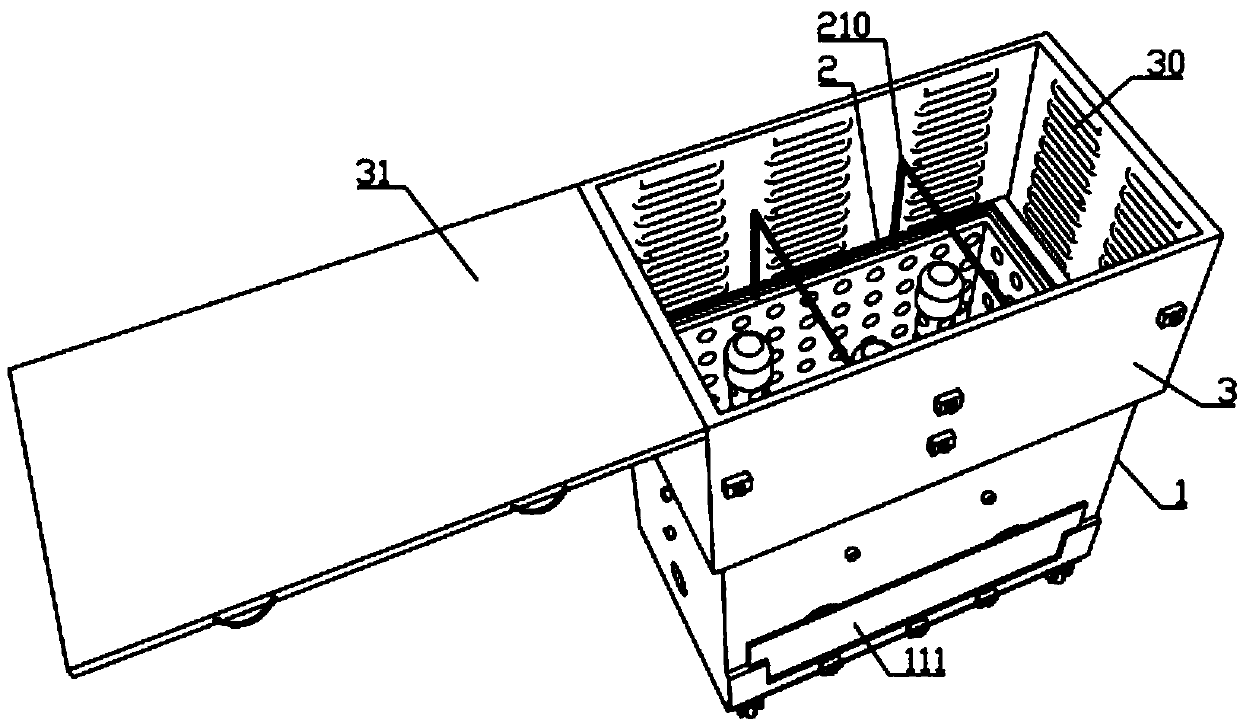

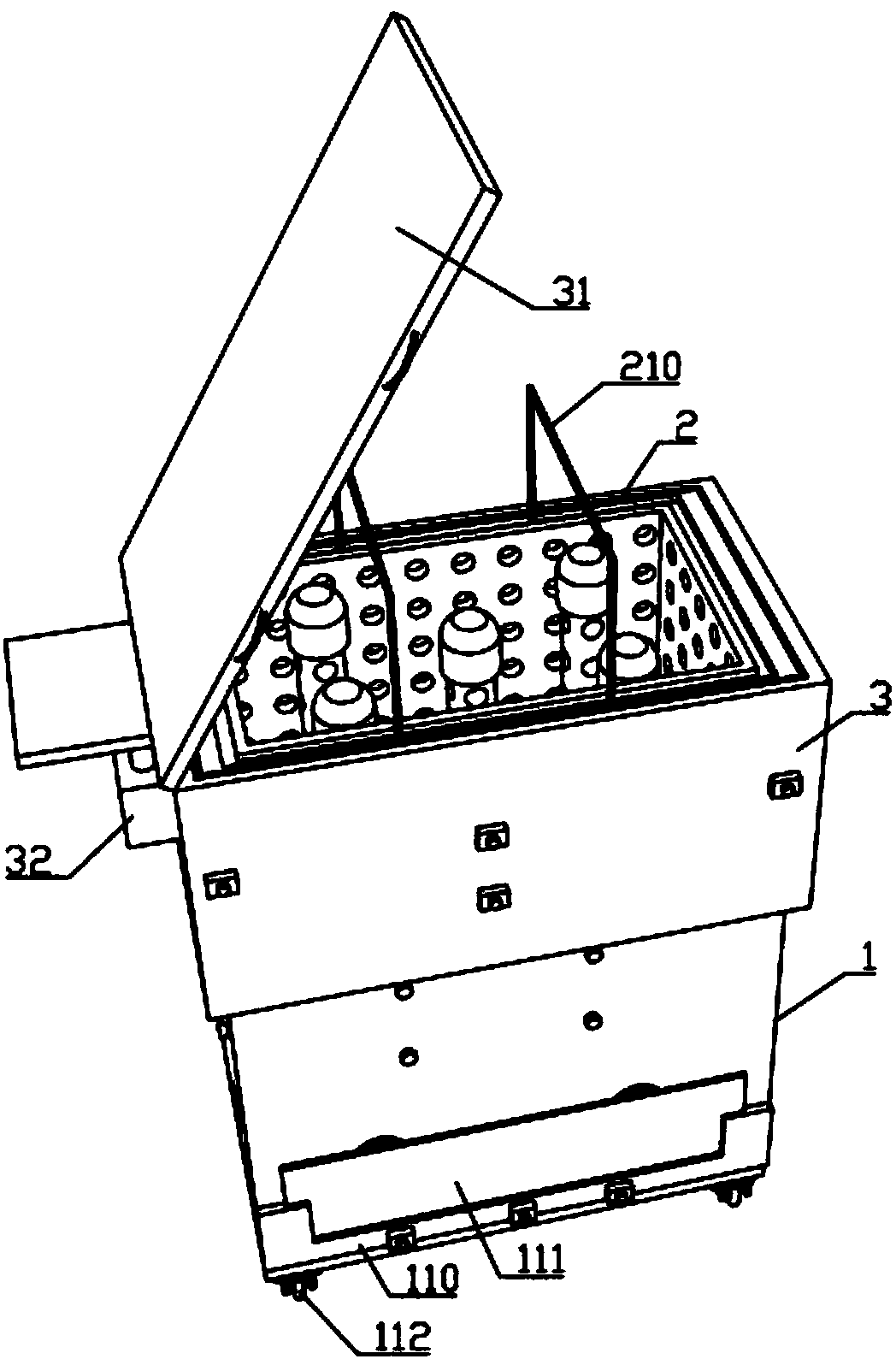

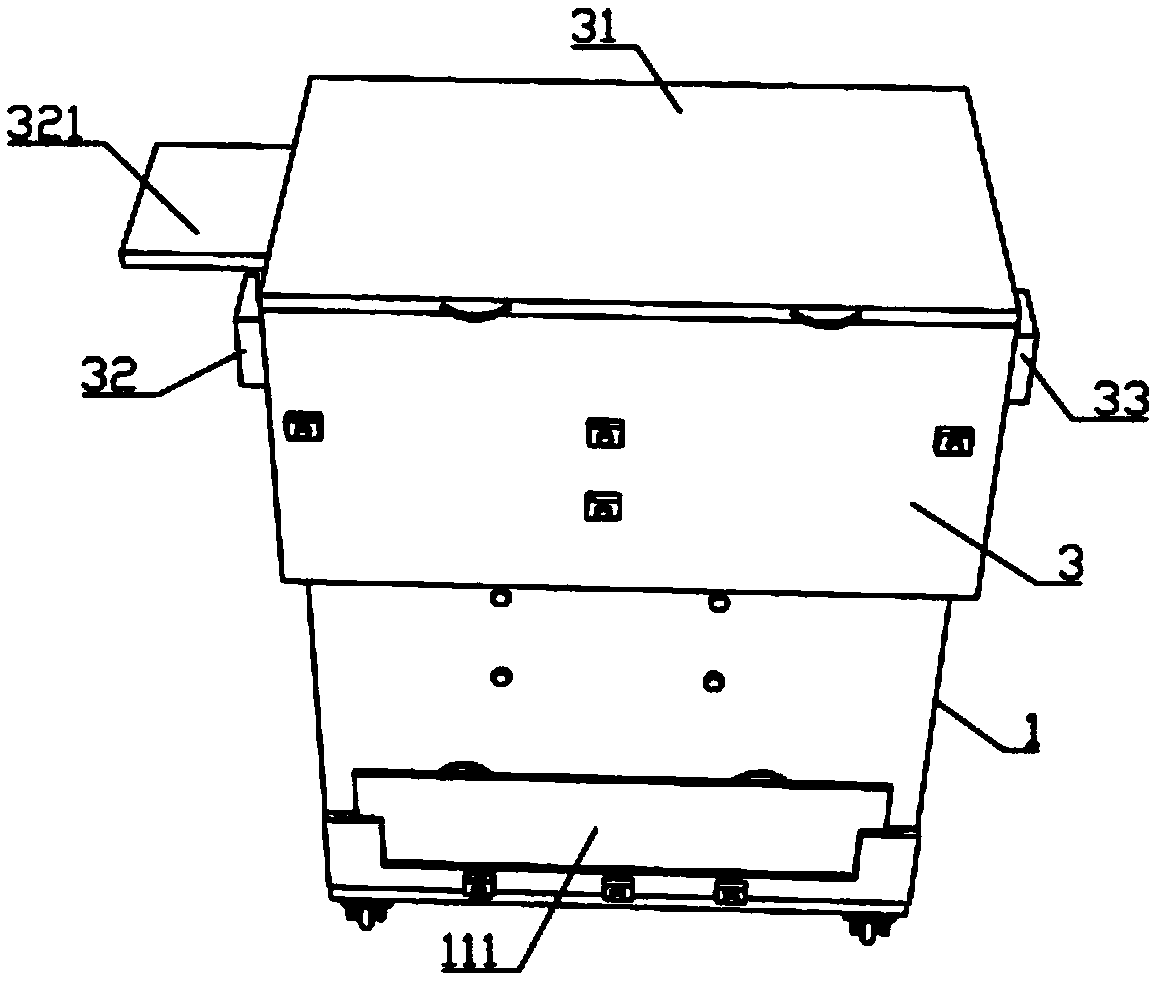

[0031] Such as Figure 1 to Figure 12 As shown, an ultrasonic cleaning device capable of drying workpieces of the present invention includes a cleaning tank 1 and a basket 20 in the shape of a cuboid with an open top. The front wall, rear wall, left wall, and right wall of the basket 20 are Both the bottom and the bottom are provided with a plurality of second through holes, and also include a drying box 3;

[0032] The cleaning tank 1 is integrally formed by an upper box body 10 and a lower box body 11, the top of the upper box body 10 is open, the basket 20 can be stuck in the upper box body 10, the upper box body 10 can be filled with cleaning liquid, and the lower box body 11 Both the top and the front part of the upper box are open, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com