Split type water-permeable brick

A permeable brick, split technology, applied in roads, buildings, gutter/curbstone, etc., can solve the problems of high cost, high price, waste of materials, etc., and achieve the effect of low manufacturing cost and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

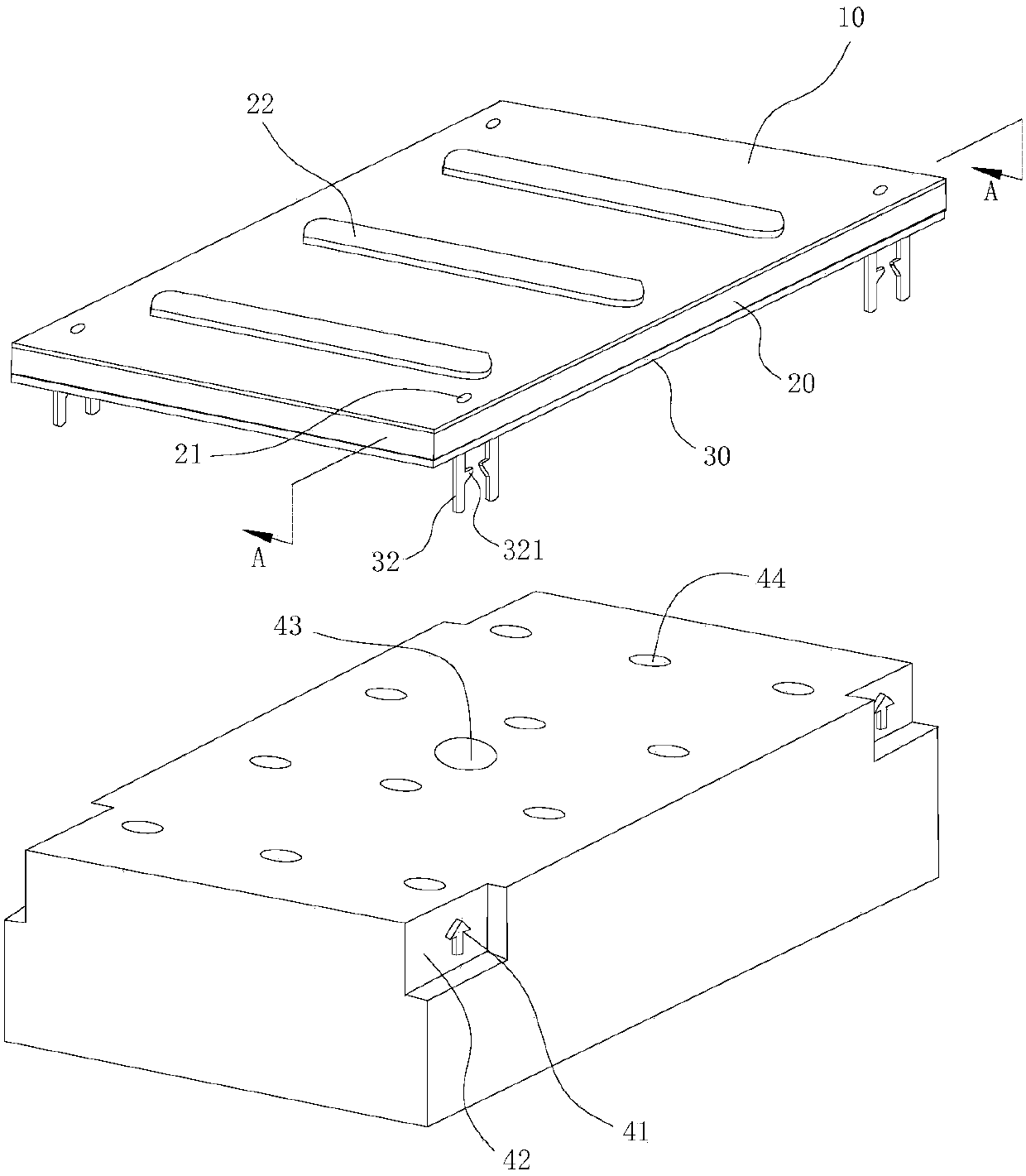

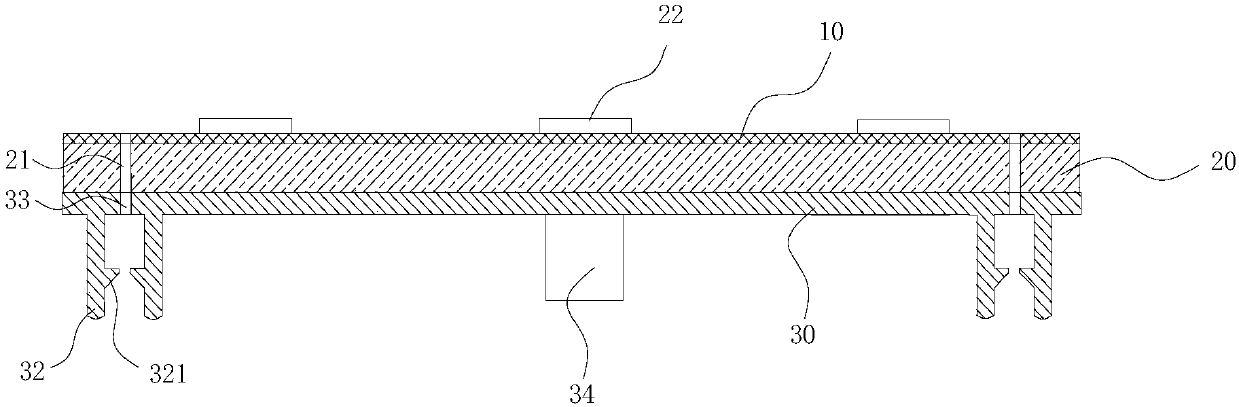

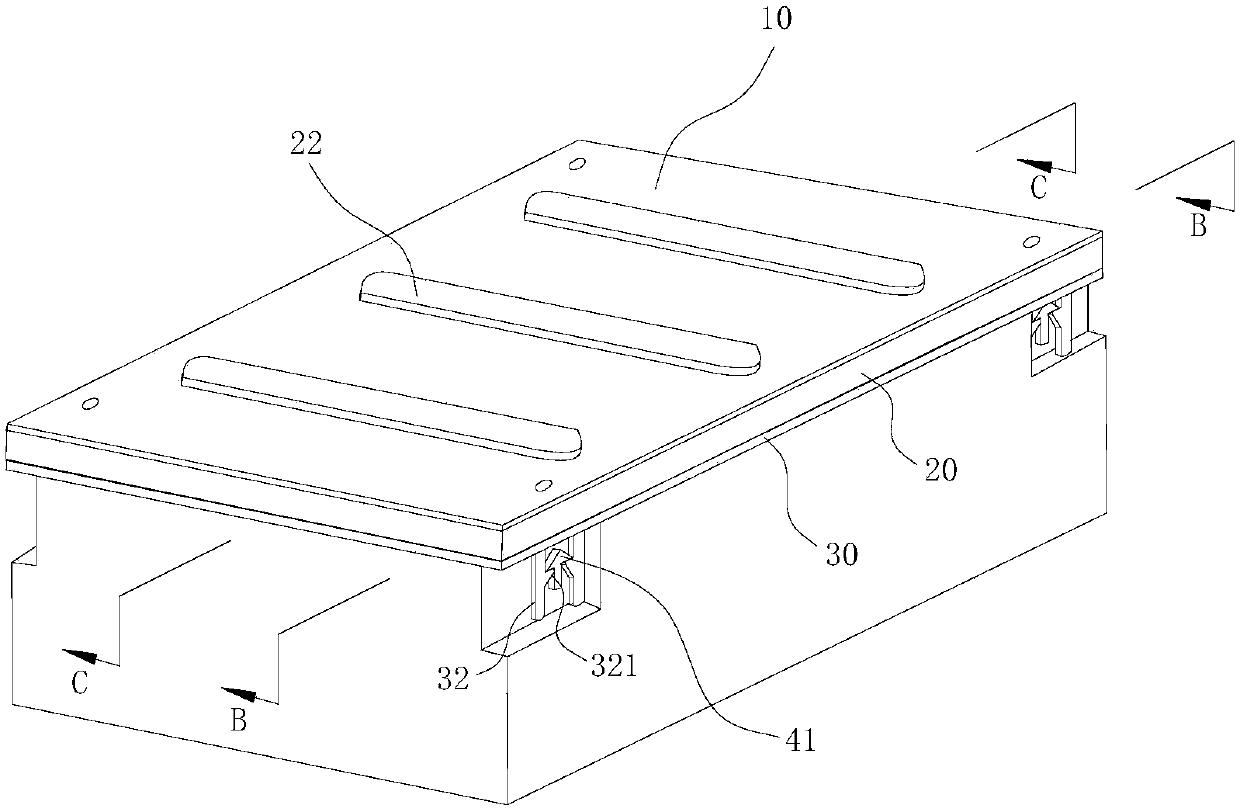

[0024] Such as Figure 1 to Figure 6 As shown, the present invention provides a split type permeable brick, comprising a non-permeable concrete layer 40 and a permeable concrete layer 20 covered on the non-permeable concrete layer 40, the impermeable concrete layer 40 is provided with water flow channels running through its upper and lower surfaces 44. The thickness of the permeable concrete layer 20 is smaller than the thickness of the impermeable concrete layer 40. The plastic bearing plate 30 has a plurality of strip-shaped buckles 32 extending vertically downwards and a plurality of disassembly buttons for tools to insert into the toggle buckles 32. The hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com