Reducing wheel and transmission chain

A technology of variable diameter wheel and transmission chain, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced reliability, increased manufacturing cost, complex transmission mechanism structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] Drive chain embodiment of the present invention is as follows in conjunction with accompanying drawing:

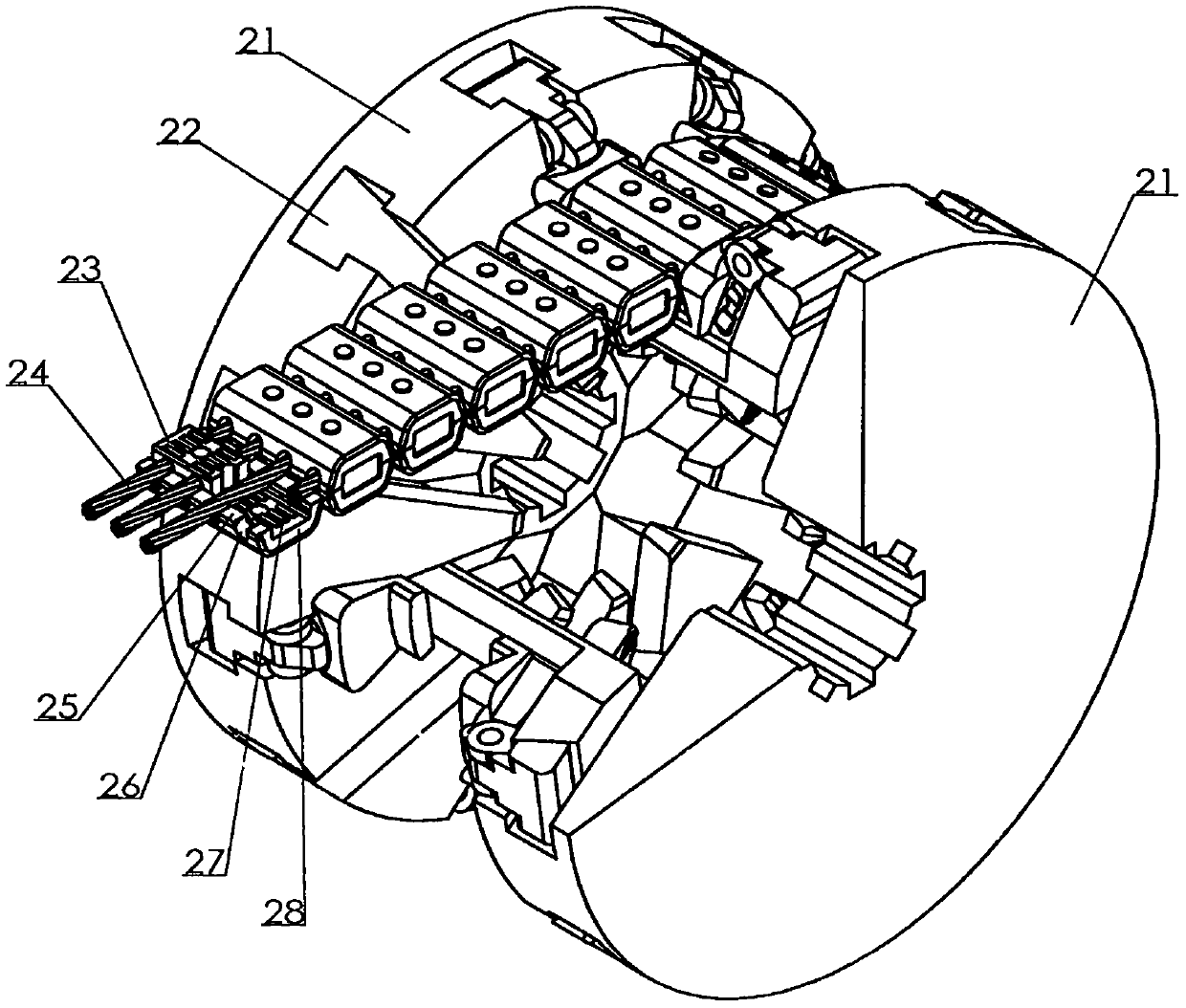

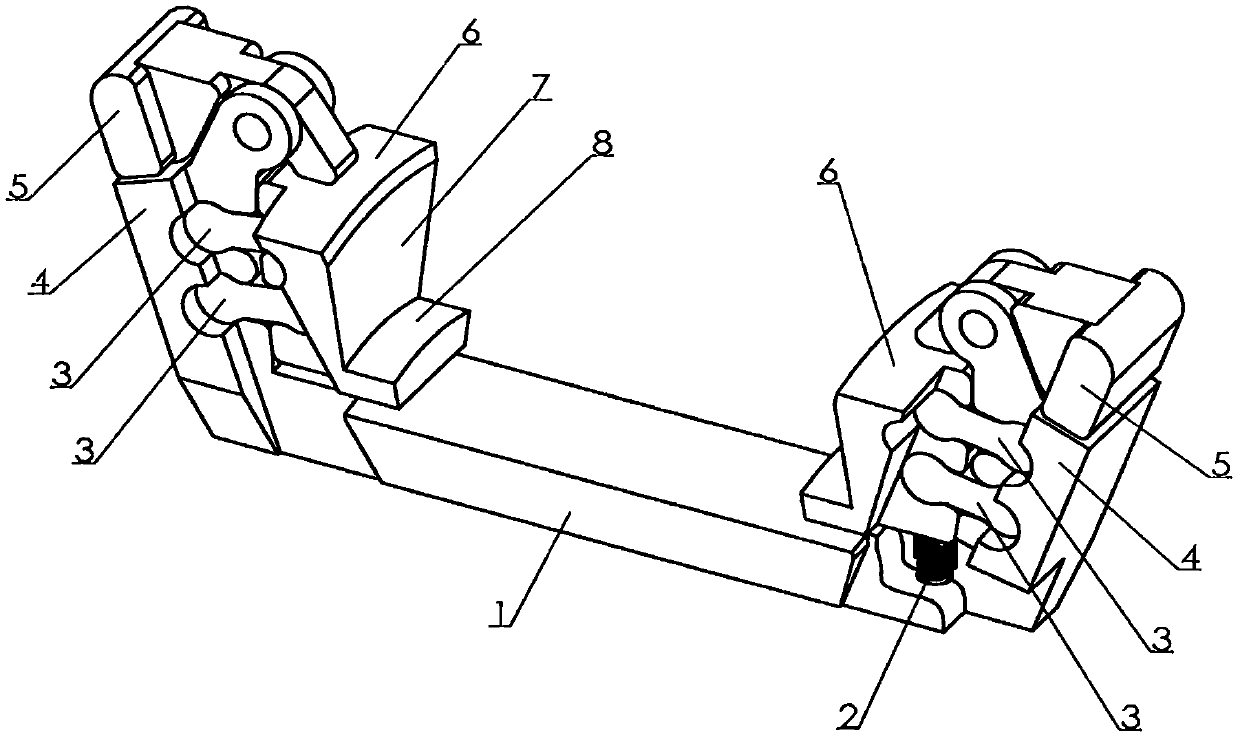

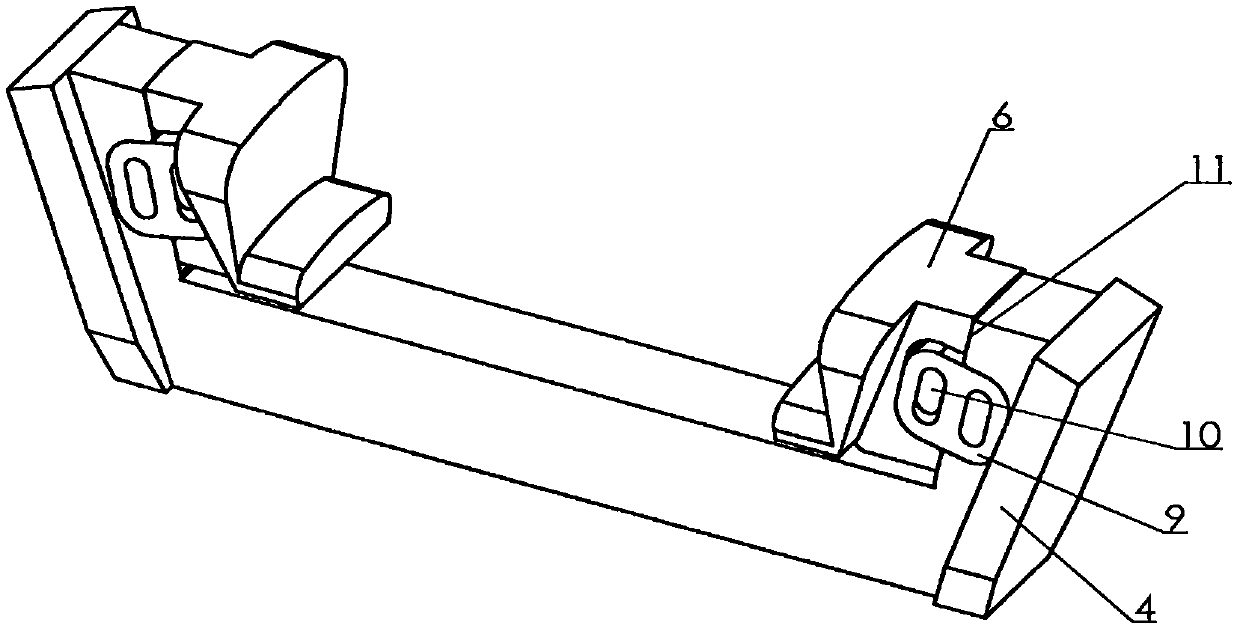

[0022] see figure 1 , the transmission chain of the present invention is formed by connecting a steel wire rope 24 with a compression block 23 and a chain link, and the chain link includes two mold boxes 25 up and down, and a plurality of protruding teeth 27 are arranged in the mold box 25, and the material of the compression block 23 is more than that of the mold The box 25 is soft. When the steel wire rope 24 passes through the pressing block 23 and is placed in the mold box 25 for end-to-end connection, the upper and lower mold boxes 25 are compressed to form a transmission chain. The use of riveting or welding processes can prevent the upper and lower mold boxes from The box 25 is separated, and the two sides 28 in the width direction of the mold box 25 can be ground with a surface grinder to form a surface contact transmission with the variable diameter wheel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com