Frequency acquisition method of butterfly plate-valve rod assembly in butterfly valve for inducing vibration of fluid

An acquisition method and butterfly plate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex force characteristics of butterfly plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

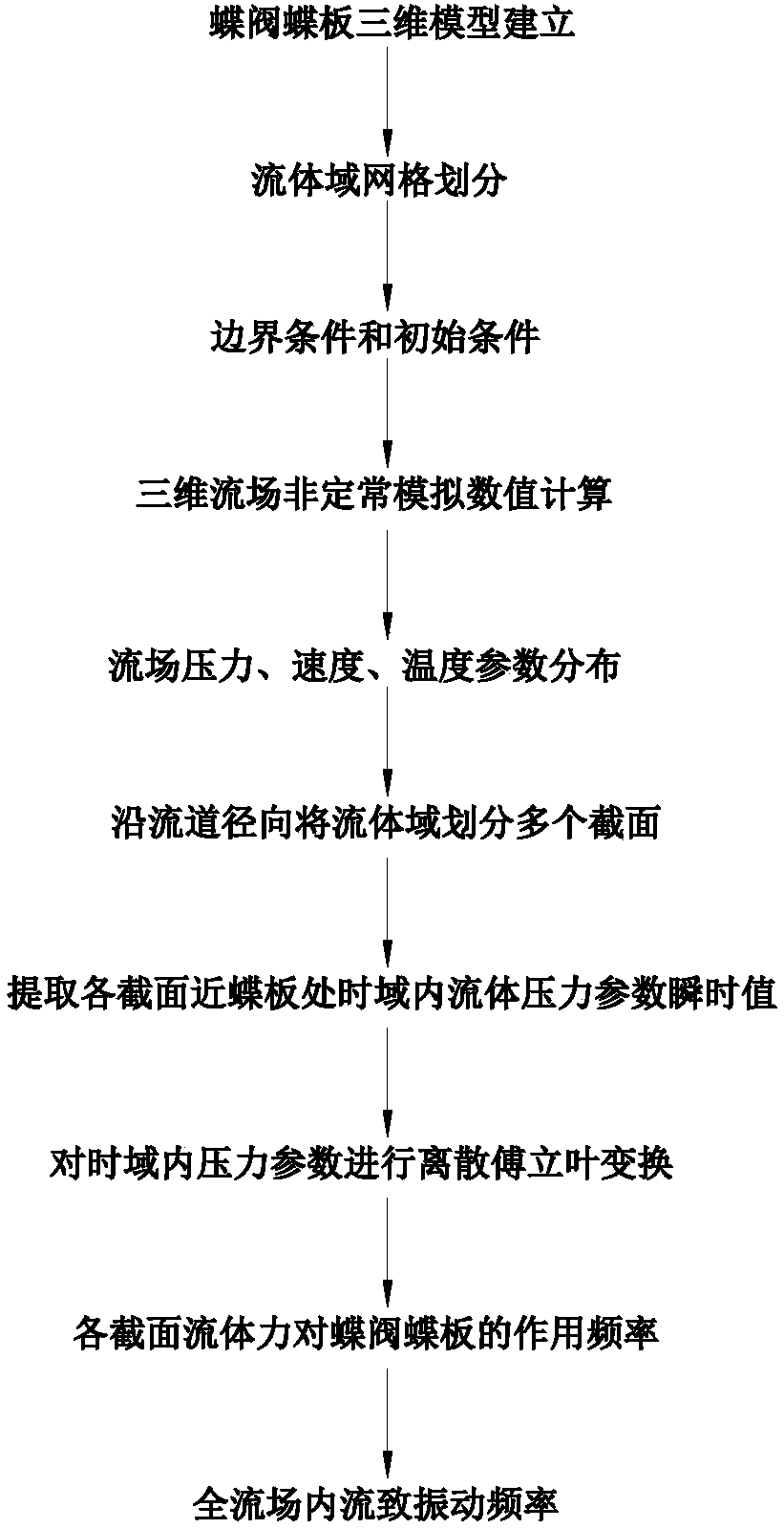

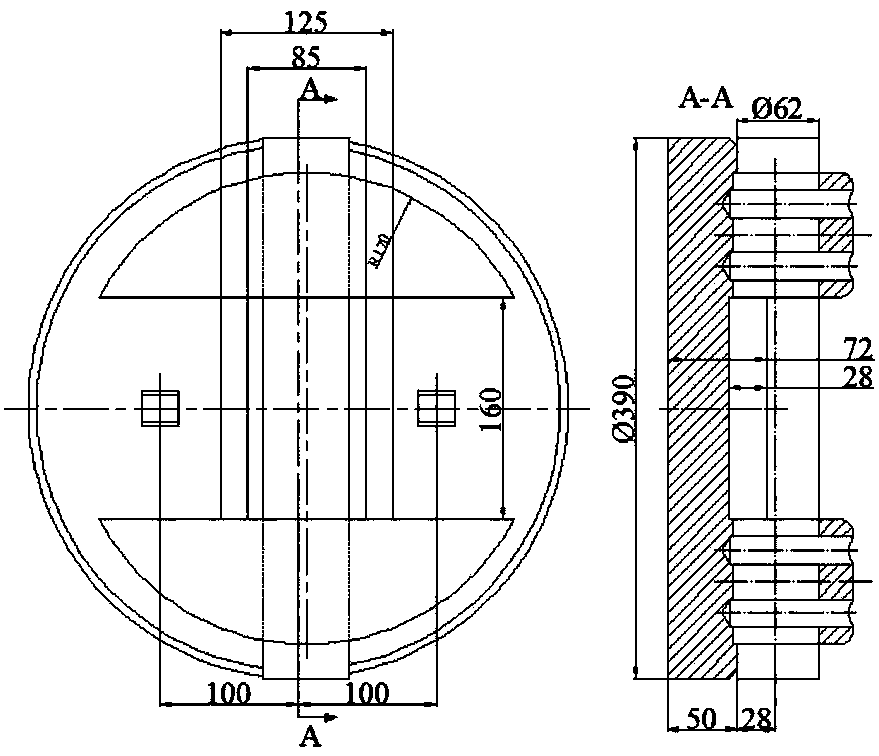

[0047] figure 1 is a schematic flow diagram of an embodiment of the present invention, figure 2 It is a two-dimensional structural diagram of the butterfly plate-valve stem assembly of the embodiment of the present invention, image 3 It is a three-dimensional structural diagram of the butterfly plate-valve stem assembly of the embodiment of the present invention, Figure 4 It is a schematic diagram of the calculation domain and the position of the butterfly plate-valve stem assembly in the calculation domain of the embodiment of the present invention, Figure 5 is the left view of the embodiment of the present invention Figure three The mesh at the eccentric butterfly plate, Figure 6 is the left view of the embodiment of the present invention Figure three Grid at the eccentric butterfly plate.

[0048] Table 1: Working condition parameter table

[0049]

[0050] Step 1, establish a three-dimensional model of the butterfly valve disc-stem assembly, see figure 2 an...

Embodiment 2

[0063] Step 1, establish a three-dimensional model of the butterfly valve disc-stem assembly, see figure 2 and image 3 . Determine the calculation domain and the position of the disc-stem assembly in the calculation domain, see Figure 4 . For the degree of mesh density and details of local mesh division near the butterfly plate and valve stem in the calculation domain, see Figure 5 and Figure 6 shown.

[0064] Step 2, using the actual working conditions of the fluid flowing through the butterfly plate-valve stem assembly shown in Table 1, the velocity and temperature values at the initial moment of the inlet of the upstream pipe section, and the pressure and temperature values at the initial moment of the outlet of the downstream pipe section are given, The three-dimensional unsteady numerical simulation calculation in the flow channel is carried out to obtain the distribution of parameters such as pressure, velocity and temperature in the flow field in the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com