A pneumatic ultra-high-speed precision seed metering device

An ultra-high-speed, seed-metering device technology, applied in the field of agricultural machinery, can solve the problems of missing filling in the seed picking stage, seed dropping in the seed transporting stage, and the impact of increased vibration on the clamping effect, so as to reduce the missed seeding rate and enhance Stability and the effect of improving seed absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

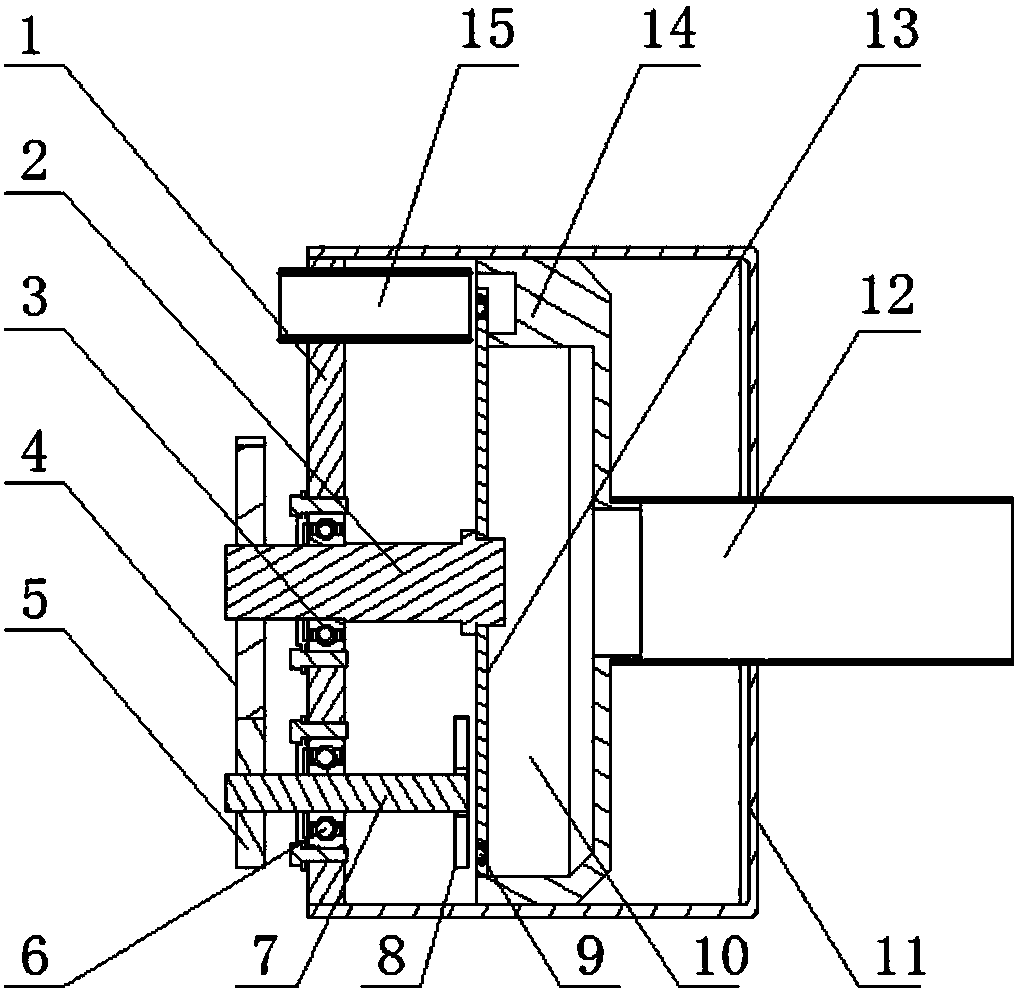

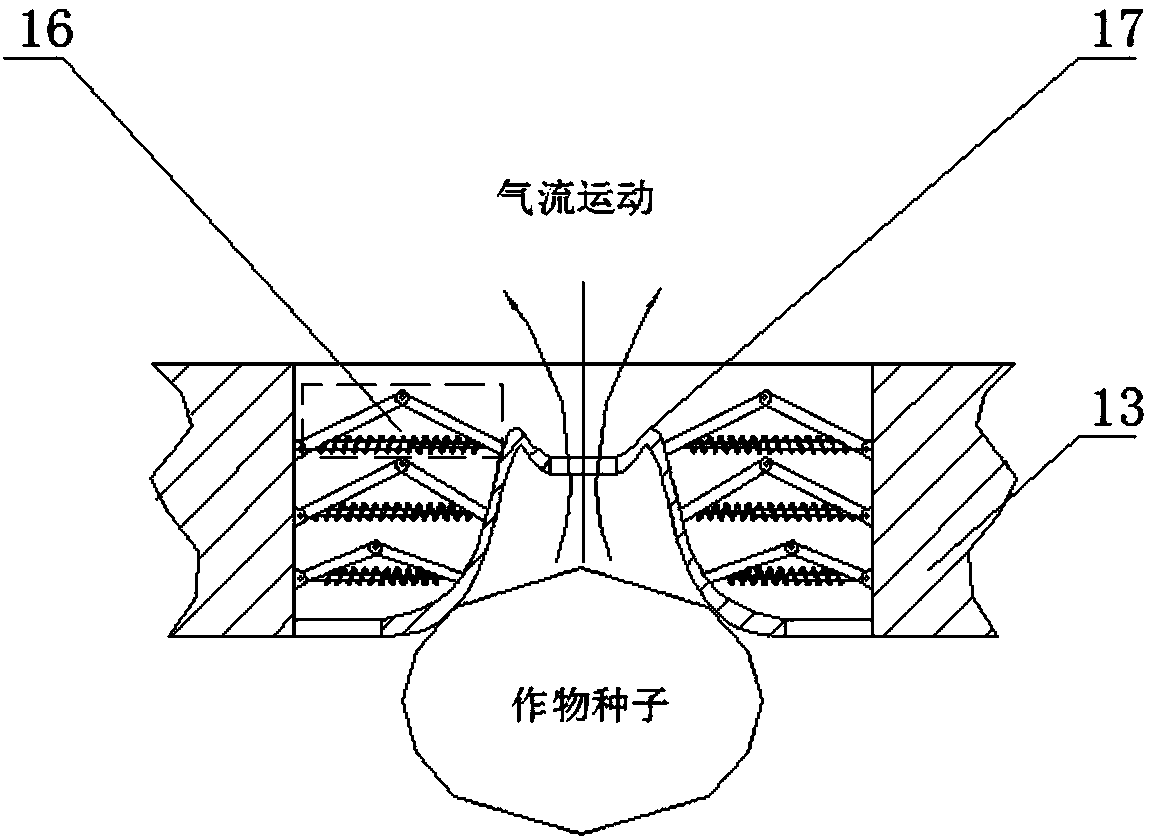

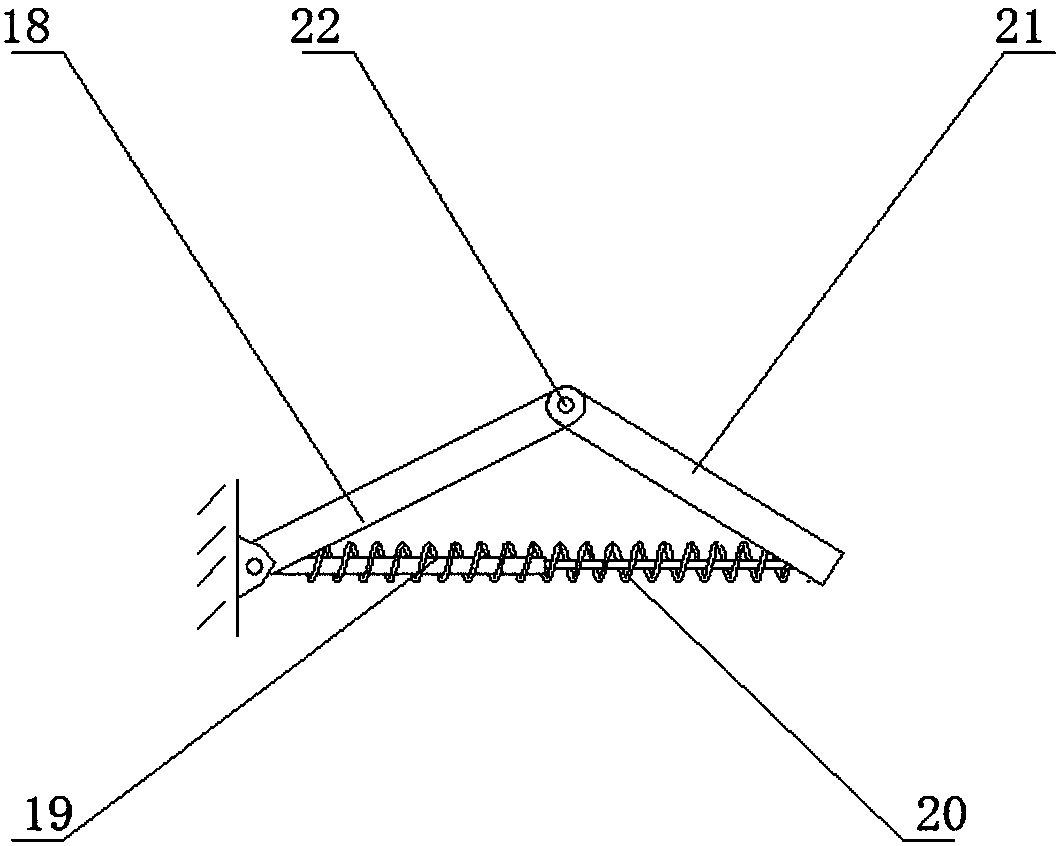

[0022] Below in conjunction with accompanying drawing, technical solution of the present invention is described in detail:

[0023] Such as Figure 1 to Figure 6 As shown, a pneumatic ultra-high-speed precision seed metering device consists of a seed metering device cover 1, a seed metering disk shaft 2, a seed metering disk bearing 3, a seed metering pipe 15, a seed suction hole 9, a bionic leech sucker 17, and a seed metering device. Disk 13, articulated transmission mechanism 16, torque sensor 19, imitation human body fingerprint structure 23, flexible extrusion wheel 8, flexible extrusion wheel shaft 7, flexible extrusion wheel shaft gear 5, seeding disk shaft gear 4, flexible extrusion wheel bearing 6 , Rubber windshield 14, airtight bellows 10, ventilation pipe 12, and housing 11 are made up. A plurality of seed-suction holes 9 are evenly distributed on the seed-discharging tray 13, and the bionic leech sucker 17 is fixed in the seed-suction hole 9 by a hinged transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com