Fire-fighting equipment

A fire extinguishing equipment and frame technology, applied in fire rescue and other directions, can solve the problems of loss, difficult fire control, and difficulty in transporting fire water to high places, etc., to achieve the effect of increasing coverage and more rescue time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

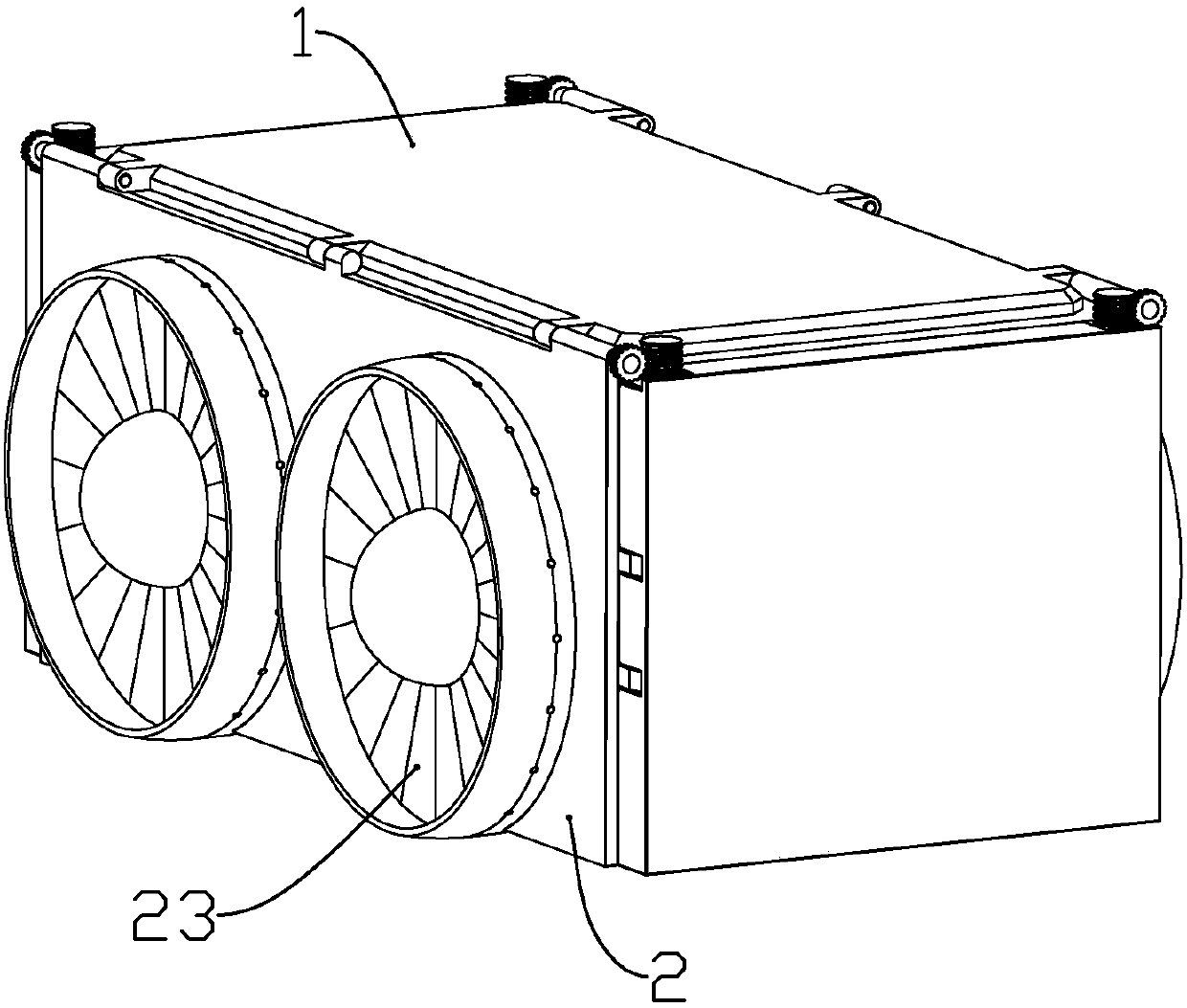

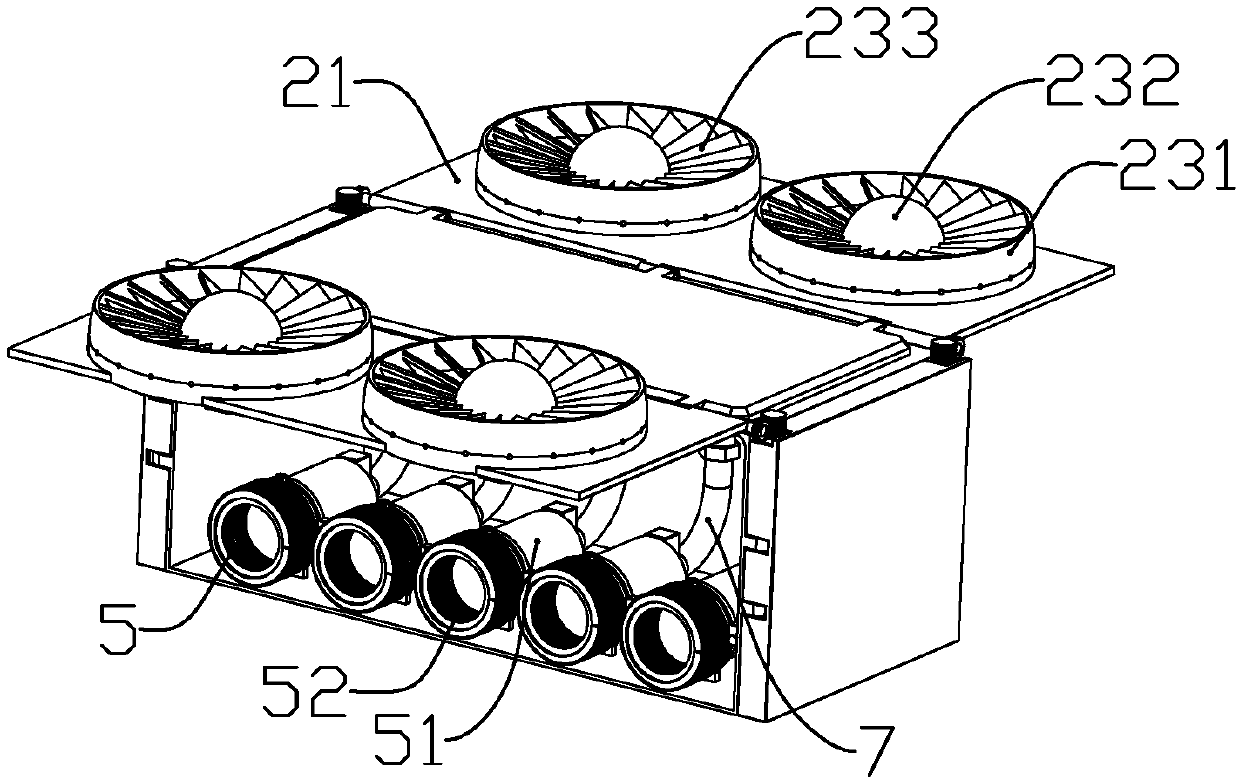

[0035] according to Figure 1 to Figure 8 As shown, this embodiment is a kind of fire extinguishing equipment, which includes a frame body 1 penetrating through the left and right sides, side plate assemblies 2 installed on the left and right sides of the frame body, a plurality of air injection pipes 7 installed in the frame body, and A plurality of guide assemblies 5 are respectively fixedly connected to one end of the jet pipe.

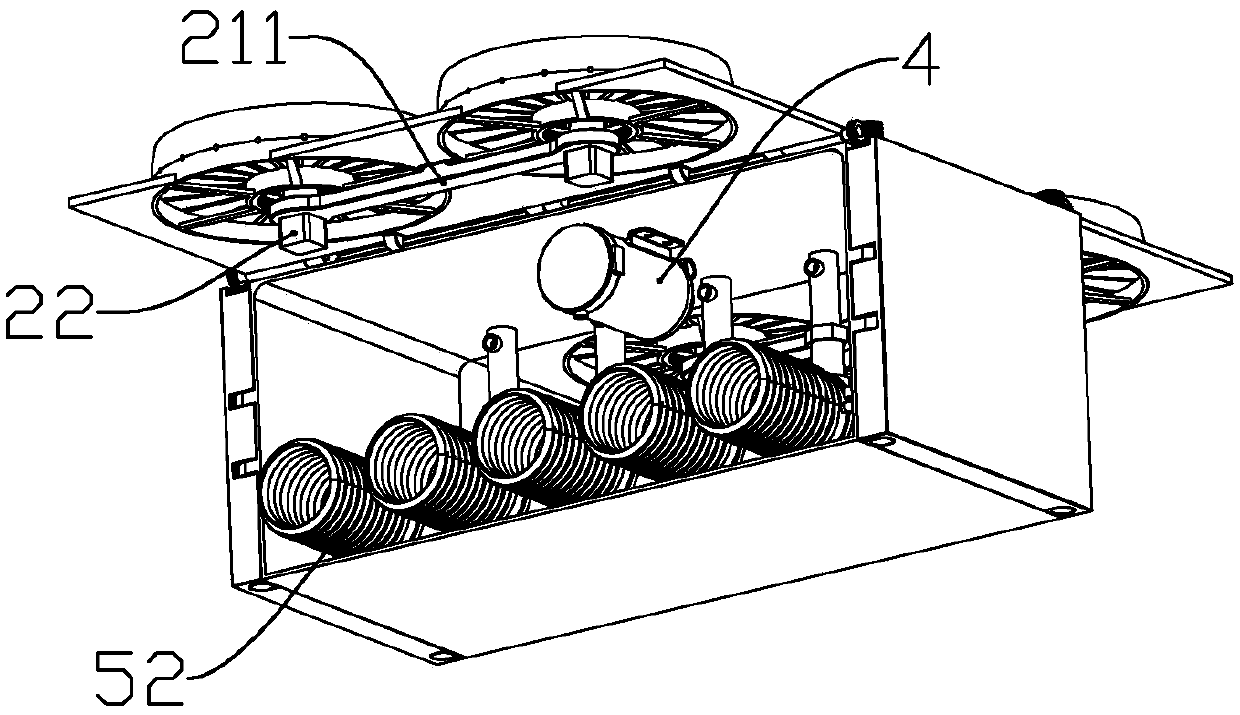

[0036] The side plate assembly includes a rotating plate 21 rotatably connected to the upper end of the frame and a fan assembly 23 mounted on the rotating plate; The mounting plate 211 of the assembly; the drive motor 22 for driving the fan assembly to rotate is installed on the mounting plate corresponding to the rotating shaft of the fan assembly; the outer edge of the fan assembly protrudes out of the rotating plate; The drive motor drives the entire fan assembly to rotate.

[0037] The fan assembly includes an inner ring 232 and an outer rin...

Embodiment 2

[0053] according to Figure 9 to Figure 11 As shown, this embodiment makes the following improvements on the basis of embodiment 1: the two ends of the rotating blades are respectively inserted into the inner ring and the outer ring; when all the rotating blades rotate to the same plane, the inner The ring is closed with the outer ring; the end of each rotating blade located in the inner ring is fixedly connected with a fourth gear 2331 .

[0054] An annular ultrasonic motor 234 coaxial with the fan assembly is installed in the inner ring; one end of the rotor of the annular ultrasonic motor faces each of the fourth gears; an annular disc is fixedly connected to the rotor of the annular ultrasonic motor 341 ; the end surface of the annular disc is formed with gear teeth meshing and drivingly connected with each of the fourth gears. Each of the rotating blades drives the fourth gear to rotate through the annular ultrasonic motor so as to rotate synchronously.

[0055] The rin...

Embodiment 3

[0058] This embodiment makes the following improvements on the basis of embodiment 1 or embodiment 2: the lower end of the frame body is detachably installed with electric grippers for grabbing high-pressure water guns or water pipes; connect. When encountering a fire, after installing the electric gripper, operate multiple devices to clamp the high-pressure water gun and the water pipe through the electric gripper and lift it up to spray the fire point to extinguish the fire. At the same time, it can also use the fire extinguishing ball to cooperate with the fire. The present invention can be controlled by only one person when extinguishing a fire, which reduces the input of personnel, so that more firefighters can participate in the rescue of the wounded; at the same time, by setting electric grippers, the equipment can spray fire extinguishing balls or pass fire Carry a high-pressure water gun for auxiliary fire extinguishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com