Washing device for easy cleaning

A washing device and spraying device technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve problems such as affecting the production efficiency and market competitiveness of enterprises, reducing the washing effect of washing towers, and increasing enterprise costs. , to achieve the effect of ingenious overall structure design, low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

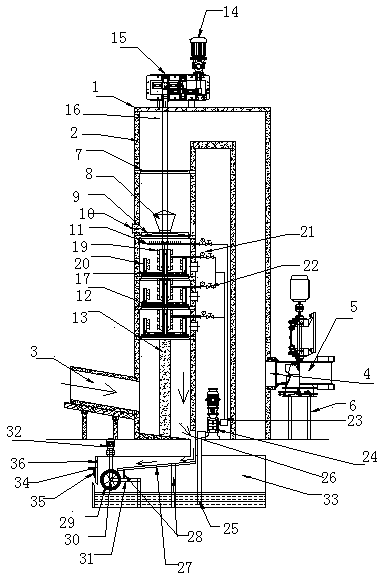

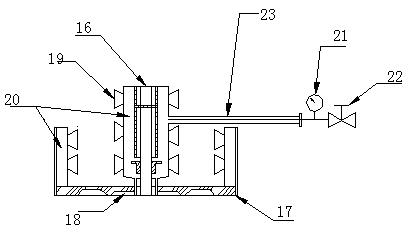

[0017] Embodiment 1: see Figure 1-Figure 2 , a washing device that is easy to clean, the washing device includes a tower assembly, a cleaning assembly, a hydraulic assembly and a filter assembly; the cleaning assembly is installed inside the tower assembly; the hydraulic assembly is installed outside the tower assembly, two The ends are respectively connected to the hydraulic cleaning assembly and the filter assembly; the filter assembly is installed under the tower body assembly. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and it is easy to maintain the product during use in the future. The tower body components include tower top 1, tower wall 2, smoke Road entrance 3, air outlet 4, induced fan 5 and induced fan support 6; the tower top and tower wall form a closed space; the flue inlet is installed on the left tower wall; the air outlet is installed on the far right On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com